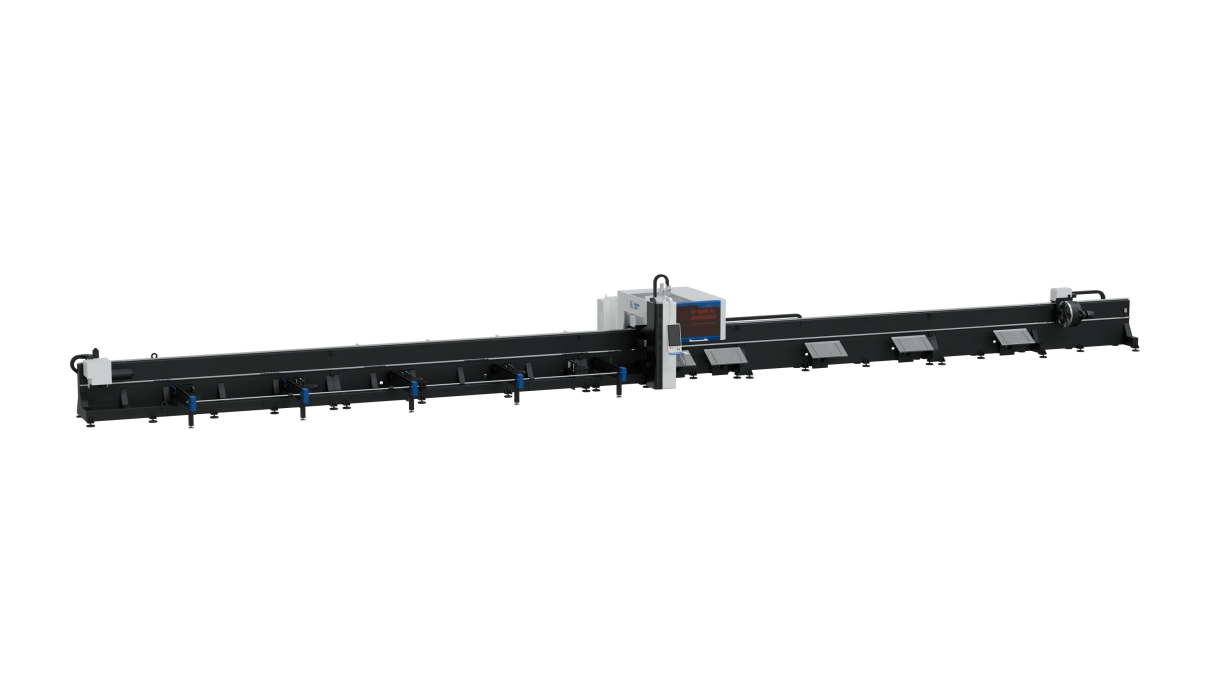

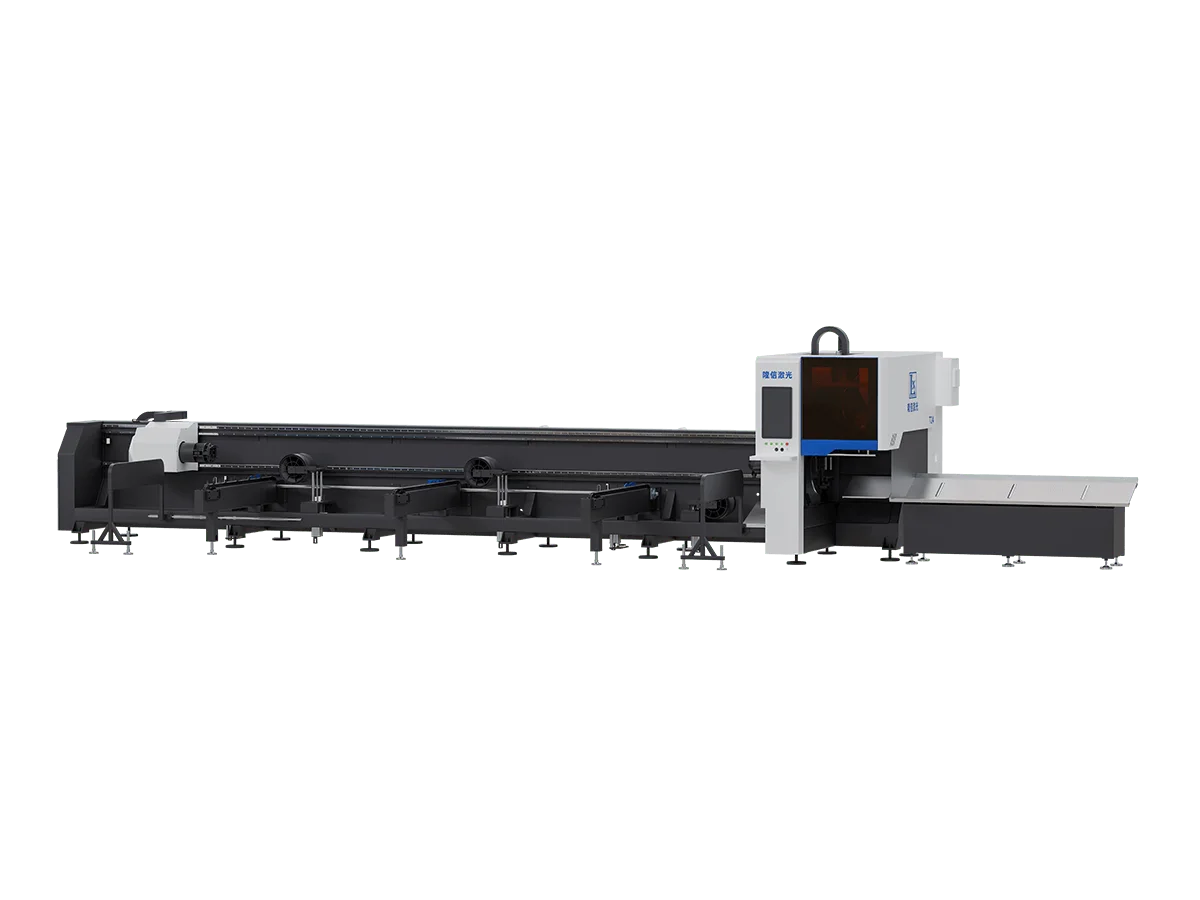

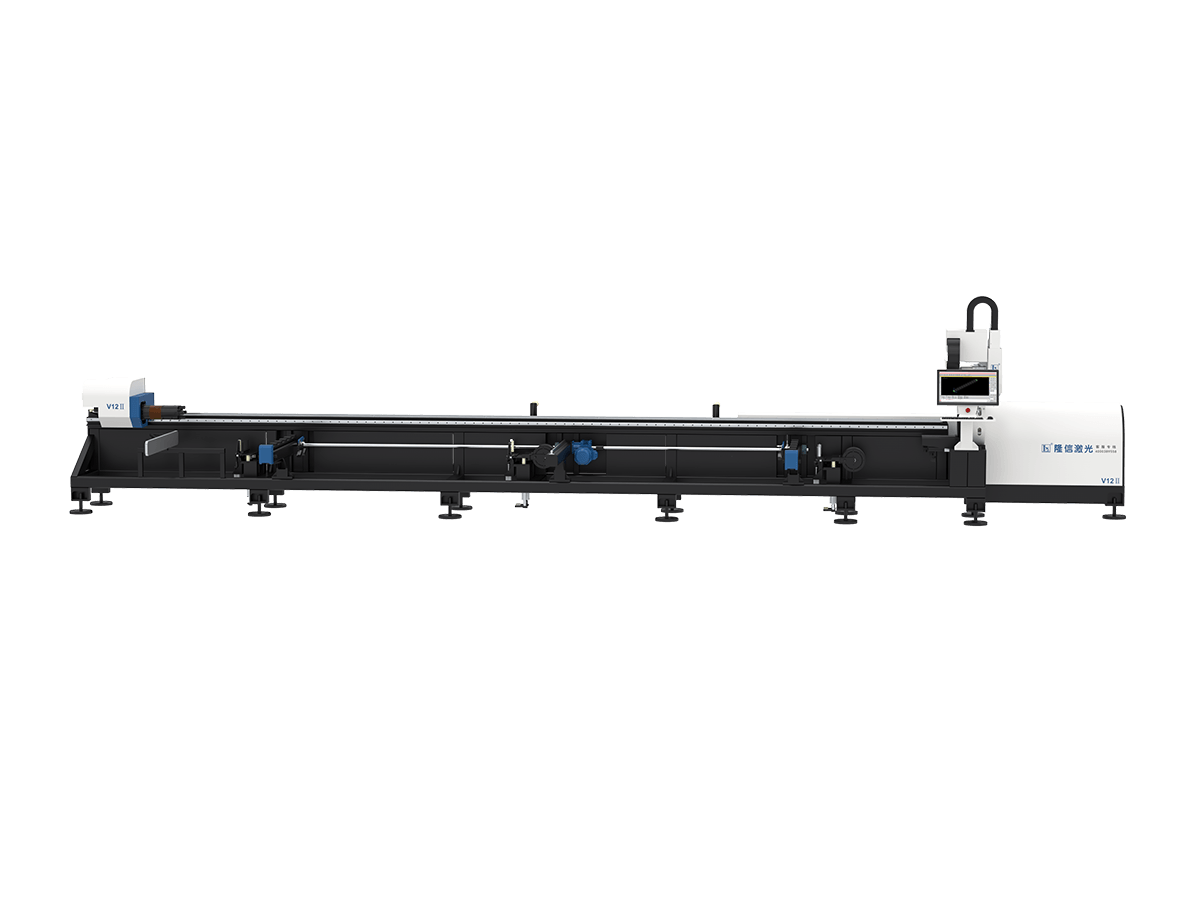

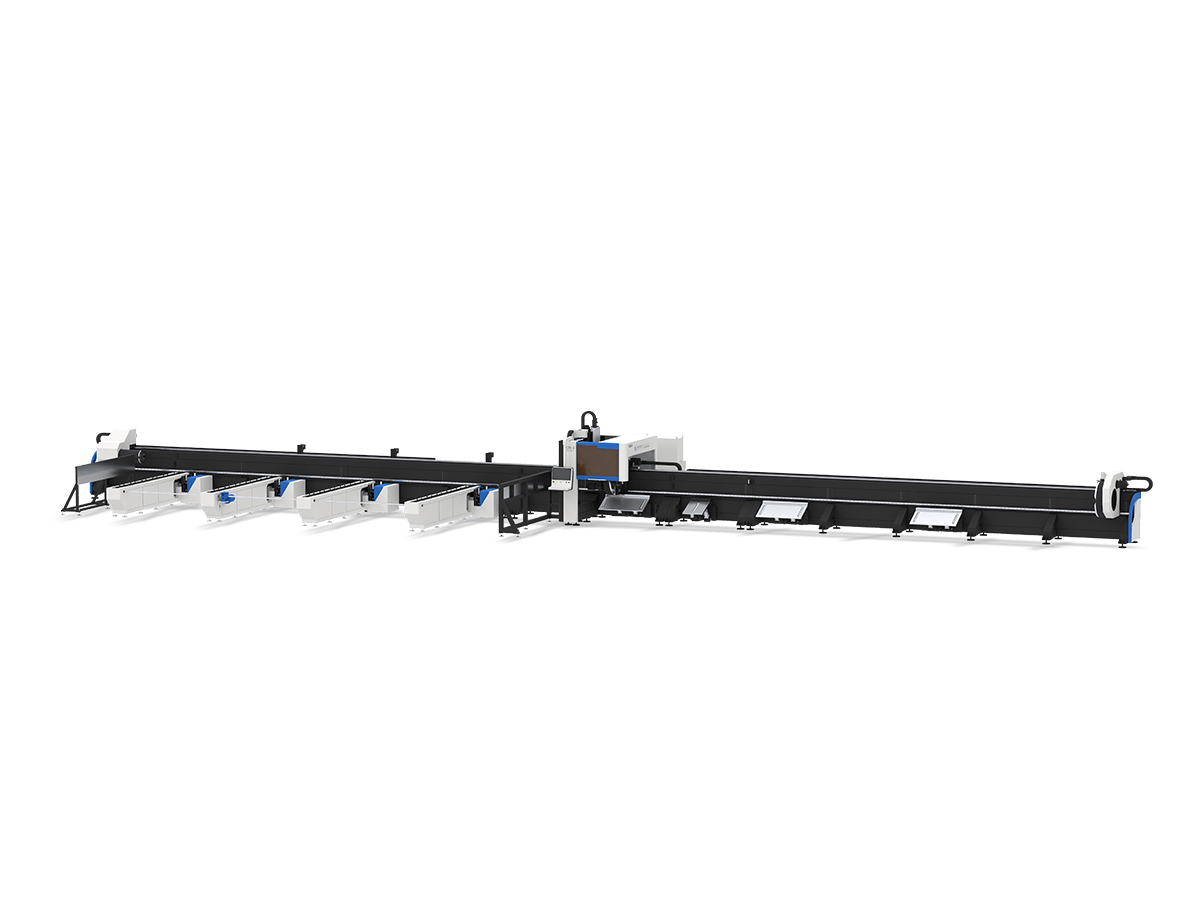

3 chucks heavy duty fiber laser pipe cutting machine

LX-K35-3

- Side-mounted bed frame for stability and efficiency

- Precision square-hole chuck: Expands square tube processing range (optional standard chuck available)

- Follow-up support: Effectively prevents workpiece deformation caused by tube sagging, improving cutting accuracy

- Zero tail material under applicable cutting conditions

- Ideal for large tube processing: Round tube: ∅40-350mm, Square tube: □40×40-350×350mm; Single tube load capacity: 1000kg

- Bevel cutting head (optional)

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Video

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

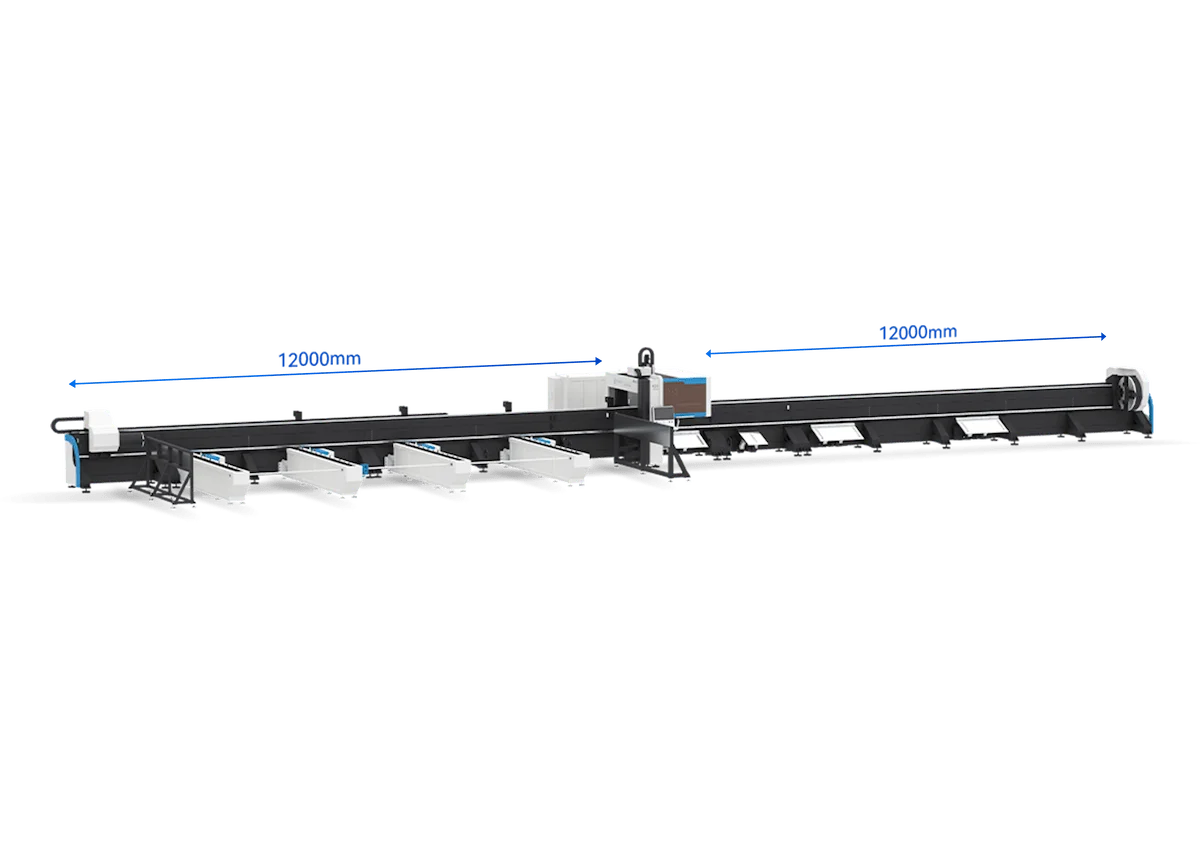

Loading range

Loading range: 12000mm, Unloading range: 12000mm. One time loading pipe: ≤3pcs.

Segmented side-mounted bed design

According to the factory floor space and the actual production needs of free choice of loading and unloading. Length of the optional specifications of the upper material: 6 metres, 9 metres, 12 metres; optional specifications of the lower material: 3 metres, 6 metres, 9 metres, 12 metres.

Fully automatic tube loading in rows

Automatic push tube loading loading, greatly improve the loading efficiency

Full stroke three chuck clamping

The three-chuck system in laser tube cutting machines enhances precision and stability for large, heavy tubes, enabling zero-tailing cuts, superior material utilization, high efficiency, deformation correction, and versatile handling of diverse tube shapes, boosting productivity and quality.