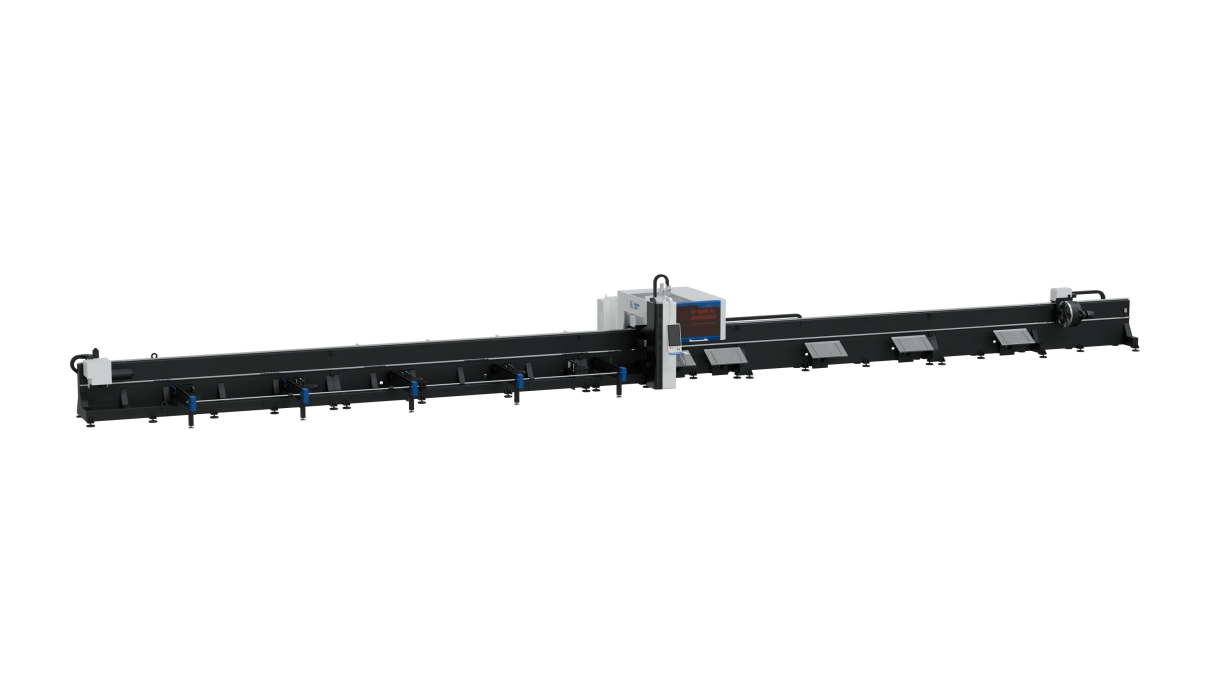

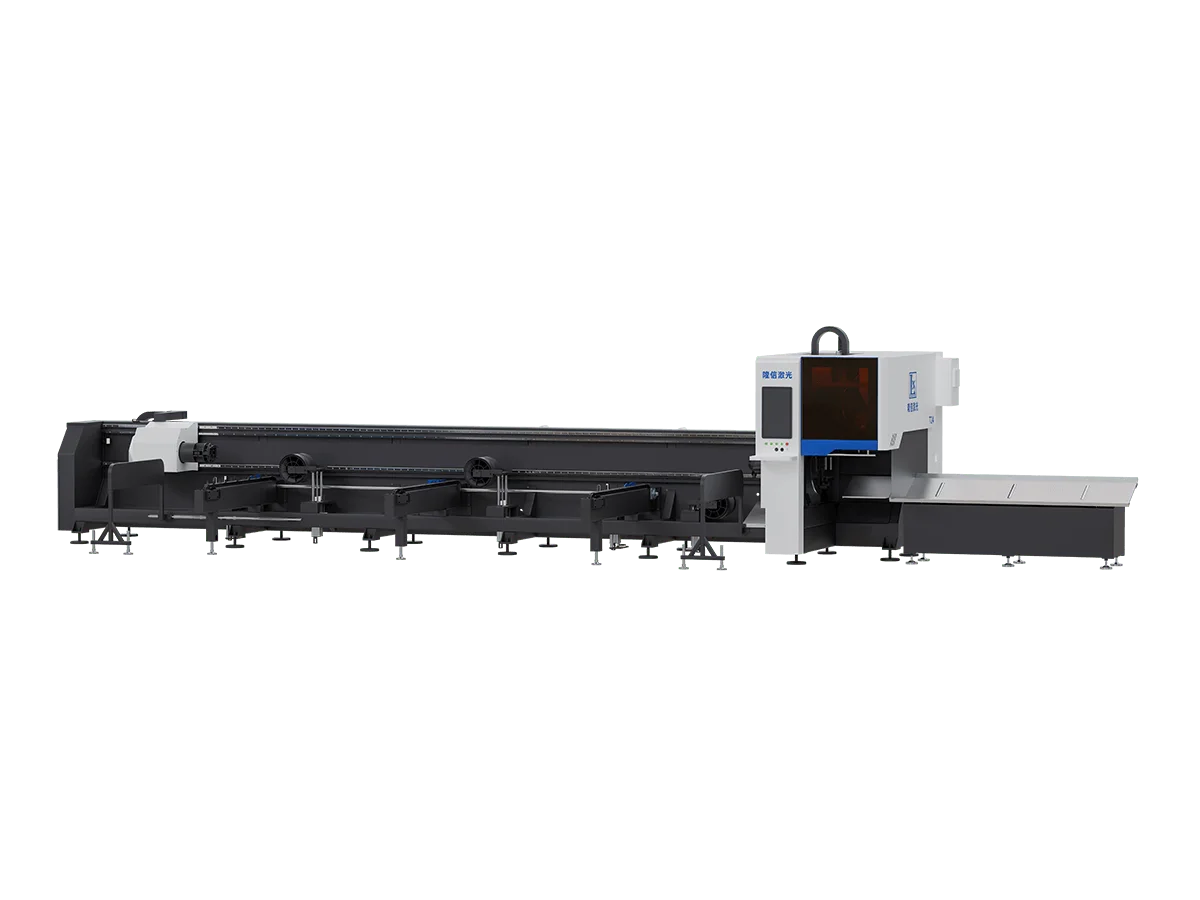

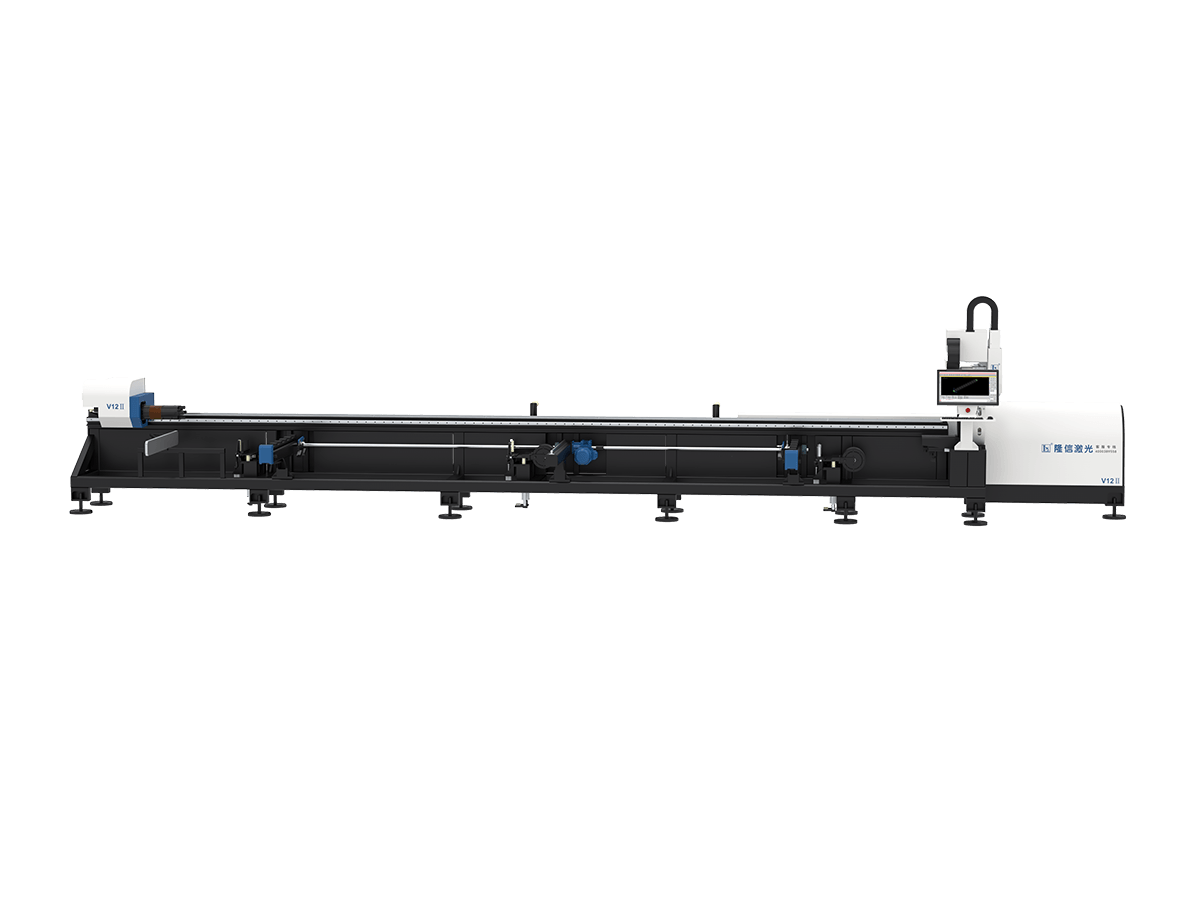

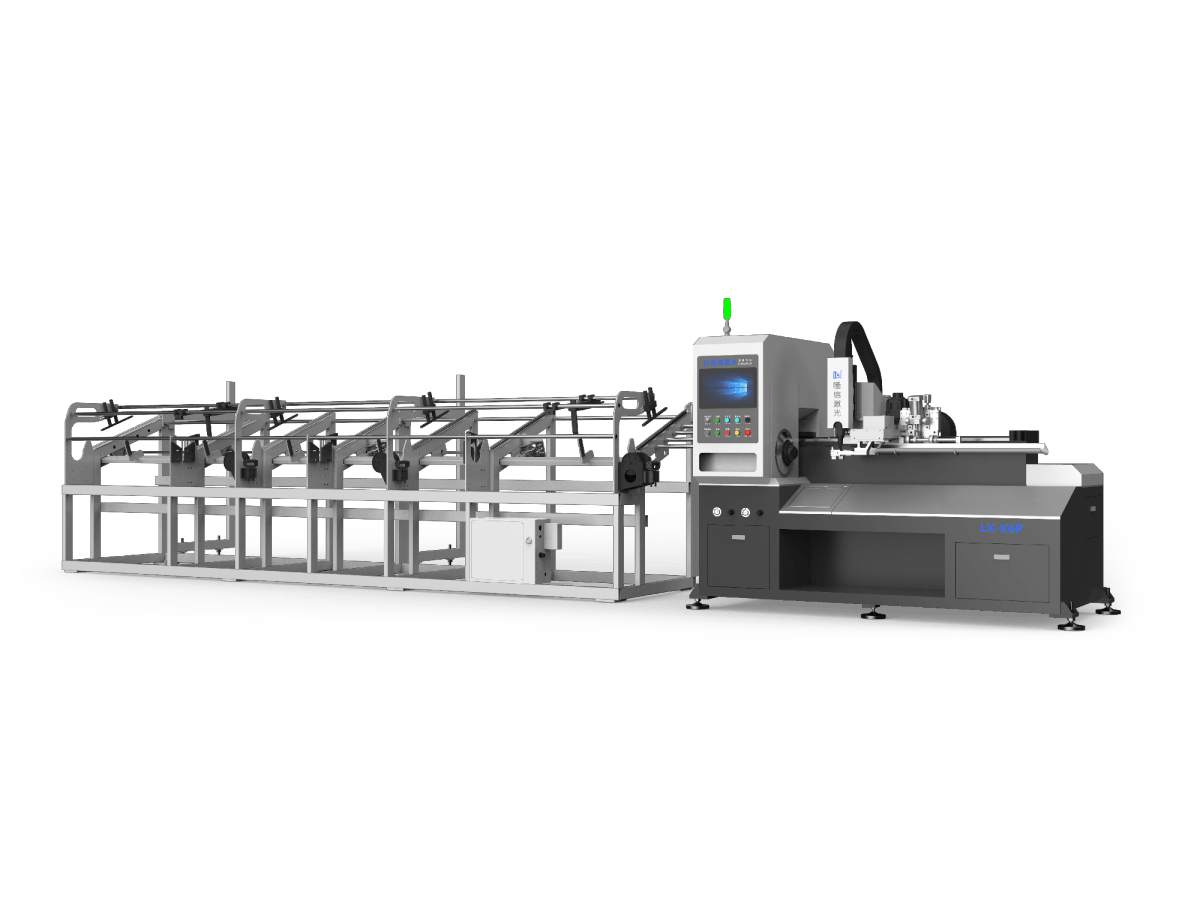

Semi-automatic cnc tube laser cutting machine

LX-K6P

- Customer-centric, combined with customer needs, fully independent research and development of hardware and software, mastering core technologies

- High-strength bed, fast speed, good stability

- Short tail material: ≥40mm

- Strong scalability, support for personalized customization

- High cost-effectiveness, fully automatic production

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Video

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

1.5G High Speed Storm Cutting

With a 1.5G acceleration, it operates 50% faster than typical laser pipe cutting machines available in the market.

Multi-tube type can be cut

Suitable for cutting various pipe materials, including round pipes, square pipes, and rectangular pipes.

Self-Developed CNC Control System

LX-proprietary Controller ensures ease of use. No prior experience required, and proficiency in cutting is achieved with minimal training.

High Cost-Effectiveness

Affordable pricing, high performance, and quick return on investment.

.png.webp)