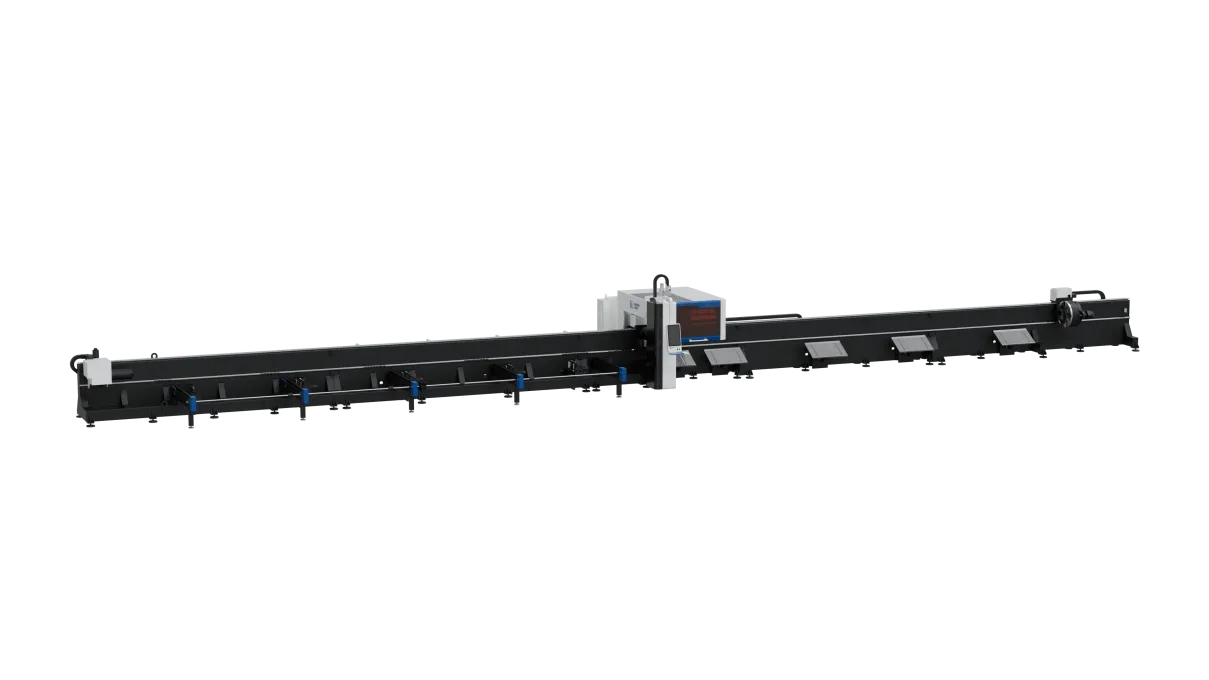

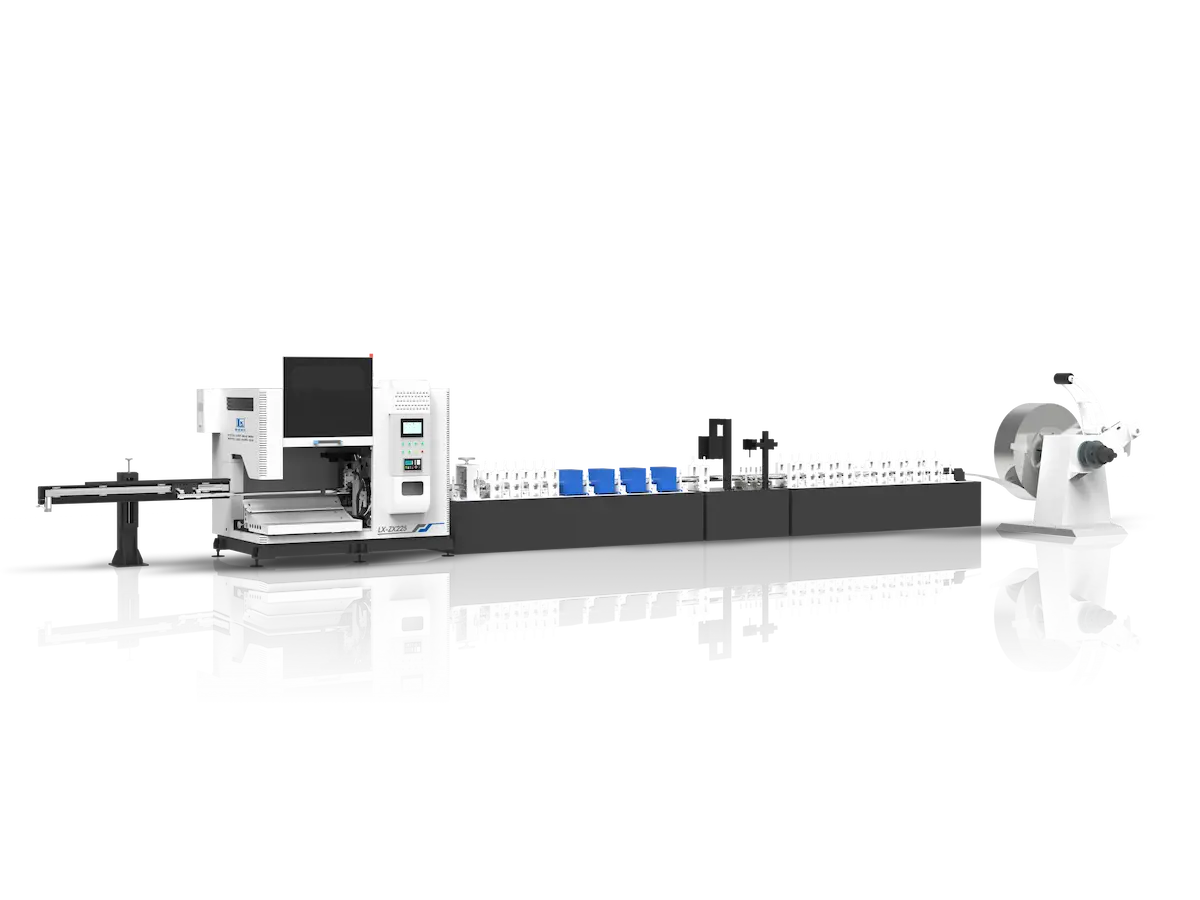

Pipe Forming and Cutting Production Line

LX-ZX225

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

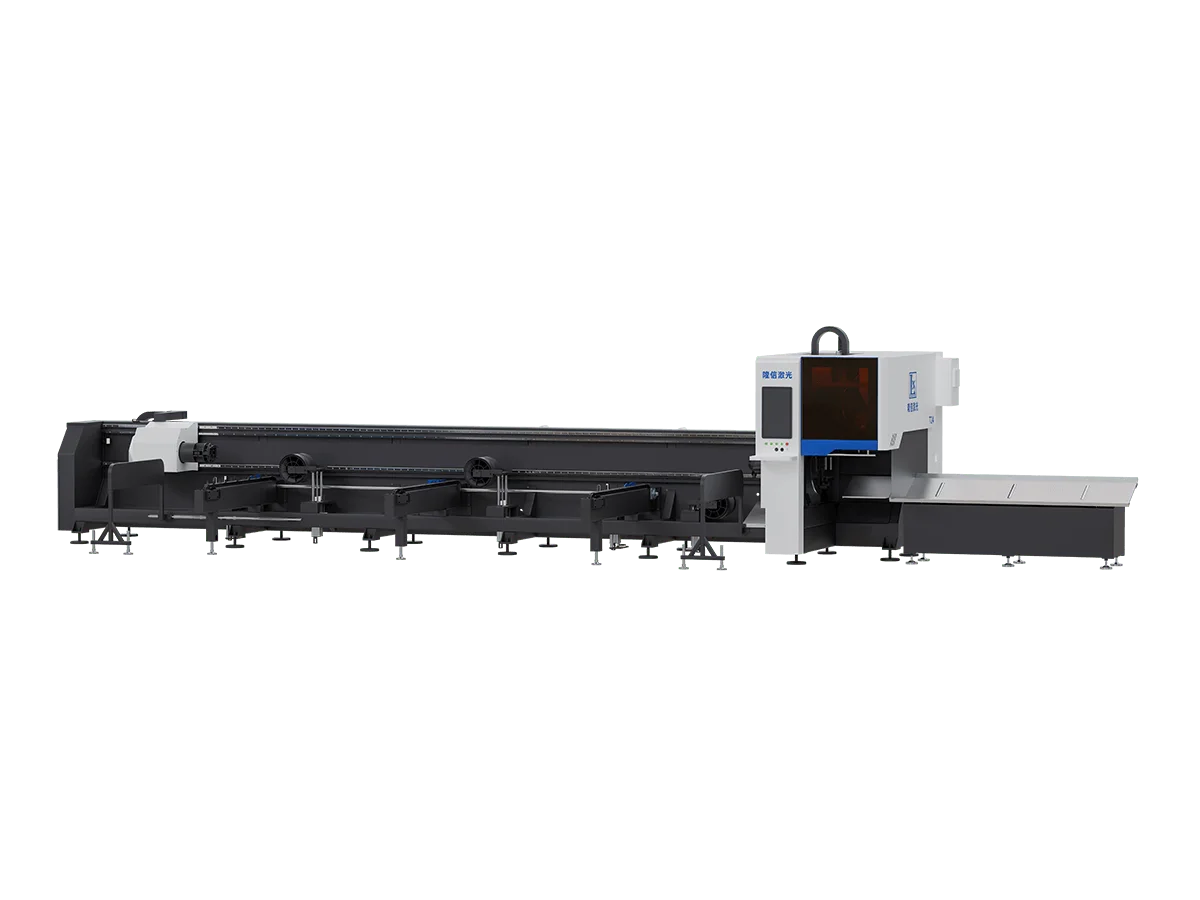

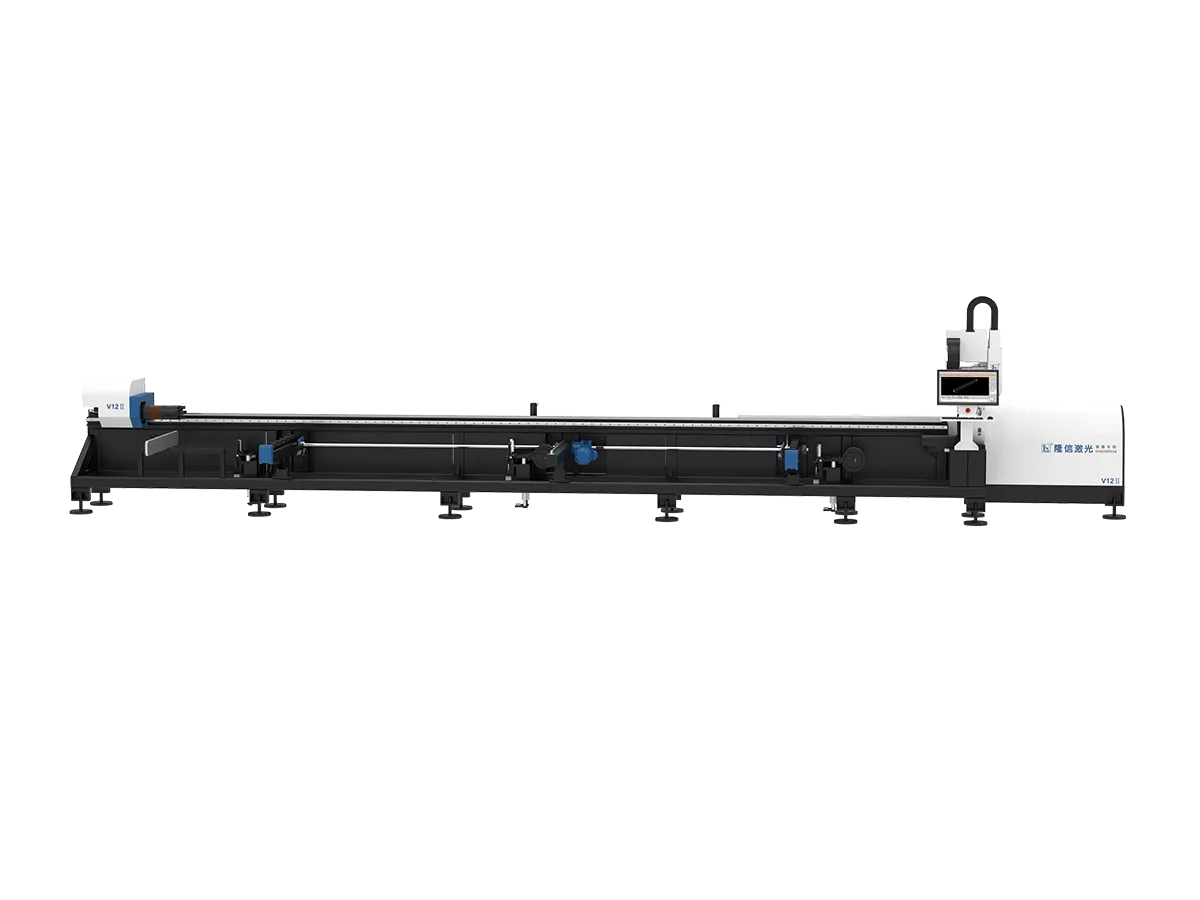

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

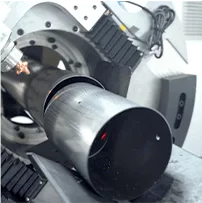

Excellent Stability and High Cutting Quality

The ZX225 model boasts a stable mechanical structure that ensures no deformation or burrs at the cut ends. It can operate continuously for 24 hours, eliminating the need for secondary processing of the cut pipes.

Internal Residue Removal Function

For keeping the interior of the pipes clean, making the materials suitable for a wider range of industries.

Adjustable Feeding Rate

The material feeding rate is adjustable to maintain synchronization with pipe production efficiency.

Multiple Size Options

ZX225 comes in various size versions, allowing you to select the one that best suits your needs, capable of cutting pipes ranging from 40 to 350 in size.

Cutting Samples

Success Stories