มุมมองภาพรวม

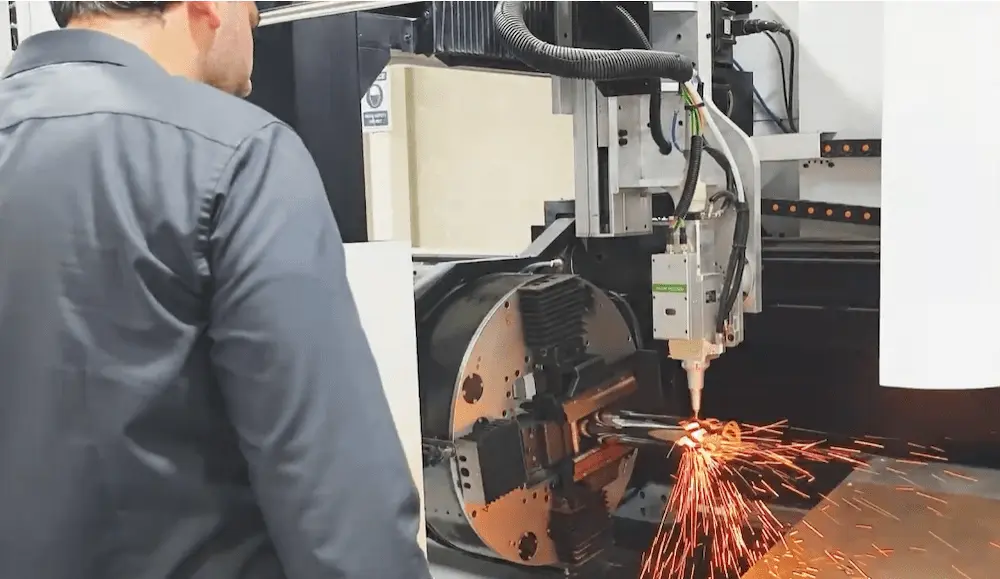

A leading automotive parts manufacturer in Türkiye modernized its round‑tube processing to achieve higher throughput, consistent quality, and minimal manual labor. Longxin delivered a turnkey, fully automated line to meet these goals.

Challenge

-

High Volume: Thousands of tubes per shift needed processing.

-

Tight Tolerances: Dual‑end chamfering had to meet ±0.05 mm accuracy for assembly.

-

Labor & Time: Manual cutting and deburring were slow, inconsistent, and costly.

Solution

Longxin’s 2.0G High‑Speed Circular Pipe Cutting Machine was integrated into a fully automated line featuring:

Automatic Conveying & Lifting

- Hands‑free feeding, measurement, and positioning.

- Precision lift aligns each tube for cutting.

High‑Speed Cut‑Off Module

- 2.0G cutting speeds cut cycle times by over 40%.

- Optimized blades for steel and aluminum alloys.

Dual‑End Chamfering Station

- Simultaneous chamfering of both ends for uniform edge quality.

- Adjustable angles for various fittings.

Centralized Control System

- PLC interface for recipe management and real‑time monitoring.

- Data logging for quality traceability.

Results & Benefits

-

Throughput +55% – Easily handles peak order volumes.

-

Precision ±0.05 mm – Consistent dimensional accuracy.

-

Labor –70% – Automation cut manual hours by more than two‑thirds.

-

Enhanced Safety – Enclosed stations protect operators.