Rohrlaser are highly versatile for metal fabrication. They process a wide range of tube shapes, profiles and most common metal materials with high precision and fast cycle times.

Tube shapes and profiles that can be cut

Modern tube laser cutting machines can process a wide range of tube shapes and structural profiles. From standard round and square tubes to complex open sections and custom extrusions, laser cutting enables precise contours, holes, and bevels in a single setup.

| Tube Shape / Profile | Typical Applications |

|---|---|

|

Round tubes (Ø20–600 mm)

|

Pipelines, furniture frames, bicycle frames, medical equipment |

|

Square & rectangular tubes

|

Building columns, machine frames, warehouse racking |

|

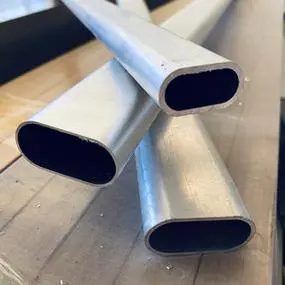

Oval & elliptical tubes

|

Fitness equipment, exhaust systems, decorative structures |

|

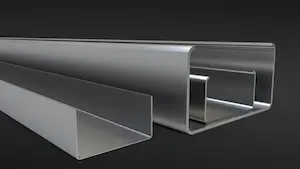

Open section profiles (C, U, L)

|

Brackets, trusses, support structures |

|

|

Shipbuilding, bridges, heavy machinery |

|

Special extruded sections

|

Agricultural machinery, architectural components |

Deep processing of structural profiles and heavy-duty shapes

Modern industrial demands have extended beyond closed-section tubes to complex structural profiles. H-beams, I-beams, angle steel, and channel steel form the backbone of construction and heavy industry, where processing quality directly impacts structural safety.

Traditional processing workflows typically involve multiple machines—saws, drilling presses, and milling machines—requiring material handling between stations. Integrated tube laser systems consolidate these operations into a single setup, dramatically improving efficiency and accuracy.

Processing open-section profiles presents unique challenges:

- H-beam processing requires the laser head to navigate between flanges and webs while maintaining consistent focal point positioning and executing collision-avoidance algorithms

- Angle and channel steel demand adaptive centering systems to compensate for asymmetric cross-sections and prevent dimensional errors during rotation

- Custom extruded profiles with complex cross-sections benefit from 3D scanning feedback and six-axis control systems, enabling millimeter-level precision alignment

Maximum processing capabilities typically include:

- Rohr Durchmesser: up to 530-600mm

- Length: up to 12 meters (depending on machine configuration)

- Weight capacity: up to 1.5 tons for heavy-duty four-chuck systems

Materials that can be cut by tube laser cutter

Tube laser cutting machines are primarily designed for metal processing. Different materials respond differently to laser energy depending on absorption, reflectivity, and thermal conductivity.

- Kohlenstoffstahl is the most commonly cut tube material. It offers high laser absorption and fast cutting speeds, making it suitable for a wide range of industrial applications.

- Edelstahl is widely used for tube laser cutting and delivers clean, oxide-free edges when nitrogen assist gas is applied, especially for decorative or visible parts.

- Aluminum alloys can be cut efficiently with higher laser power and proper gas control. Due to their high reflectivity and thermal conductivity, stable optical protection is required.

- Copper and brass are more challenging materials because of their extremely high reflectivity. With modern high-power fiber lasers and anti-reflection systems, thin to medium wall thicknesses can be processed reliably.

- Galvanized steel tubes can be laser cut, but zinc vapor management and effective fume extraction are essential to protect both equipment and operators.

- Titanium alloys are typically used in high-value applications. Laser cutting is feasible when high-purity inert gas is applied to maintain edge quality and prevent oxidation.

The maximum thickness of tube can be cut

| Material | Typical Production Thickness |

|---|---|

| Kohlenstoffstahl | 3–12 mm |

| Edelstahl | 2–8 mm |

| Aluminum alloys | 2–6 mm |

| Copper & brass | 2–4 mm |

| Verzinkter Stahl | 1–6 mm |

| Titanium alloys | 2–6 mm |

Tubes that cannot be cut

Not all tube materials are suitable for laser cutting. Some materials may cause serious safety hazards, equipment damage, or poor cutting quality.

Materials that should NOT be laser cut include:

-

Toxic gas–releasing plastics

Such as PVC, PTFE, and vinyl. These materials release corrosive or highly toxic gases during laser cutting, which can damage equipment and pose serious health risks. -

Highly flammable plastics and foams

Materials like polystyrene foam and thick polycarbonate ignite easily and may cause uncontrolled burning. -

Fiber-reinforced composites

Carbon fiber and fiberglass tubes release hazardous fumes and suffer from poor edge quality due to uneven laser absorption. -

Transparent materials

Glass and clear acrylic do not absorb fiber laser energy effectively and cannot be cut. -

High-oil natural materials

Oily wood tubes are extremely flammable and contaminate optical components.

Recommended alternatives include mechanical sawing, waterjet cutting, CO₂ lasers (for some plastics), or specialized composite cutting tools.

Important safety notes:

- PVC and chlorine-containing materials are the absolute “red line” in laser cutting. The hydrochloric acid produced corrodes machine rails, ball screws, precision lenses, and CNC systems, causing permanent damage

- ABS cutting releases hydrogen cyanide gas, threatening operator life even at low concentrations

- Verzinkter Stahl requires careful processing as zinc vapor can contaminate optics and pose respiratory hazards

Material thickness limitations:

Even suitable materials have practical limits:

- Thick copper/aluminum(>10mm) may exceed cutting capacity of lower-power systems

- Kohlenstoffstahl beyond 25-40mm requires ultra-high power lasers (10kW+)

- Rohr Durchmesser exceeding chuck capacity (typically >530-600mm) cannot be processed

Making the right investment:

Success with tube laser cutting requires matching machine capabilities to your specific material portfolio, geometric complexity, production volume, and automation requirements. Consult with equipment manufacturers to configure systems that align precisely with your application needs, ensuring optimal return on investment and long-term competitive advantage.