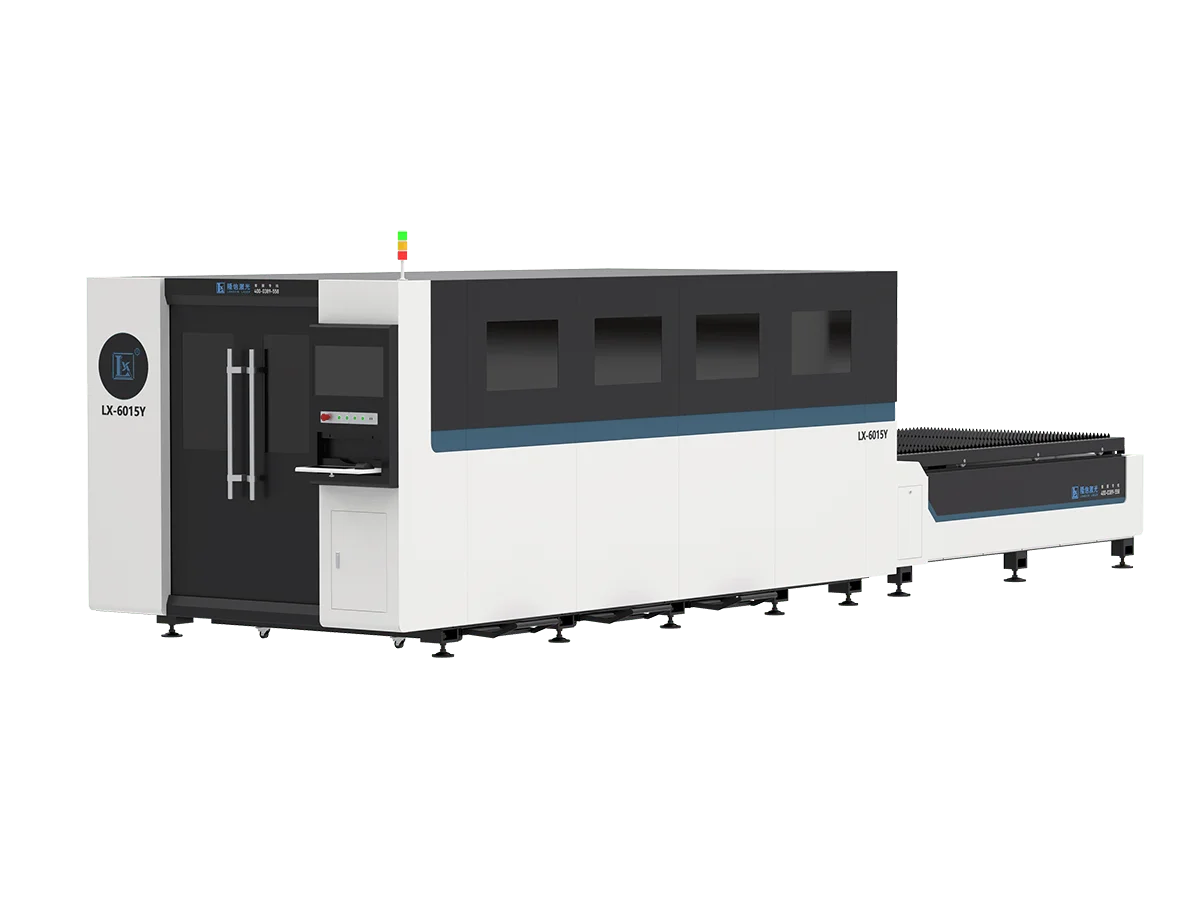

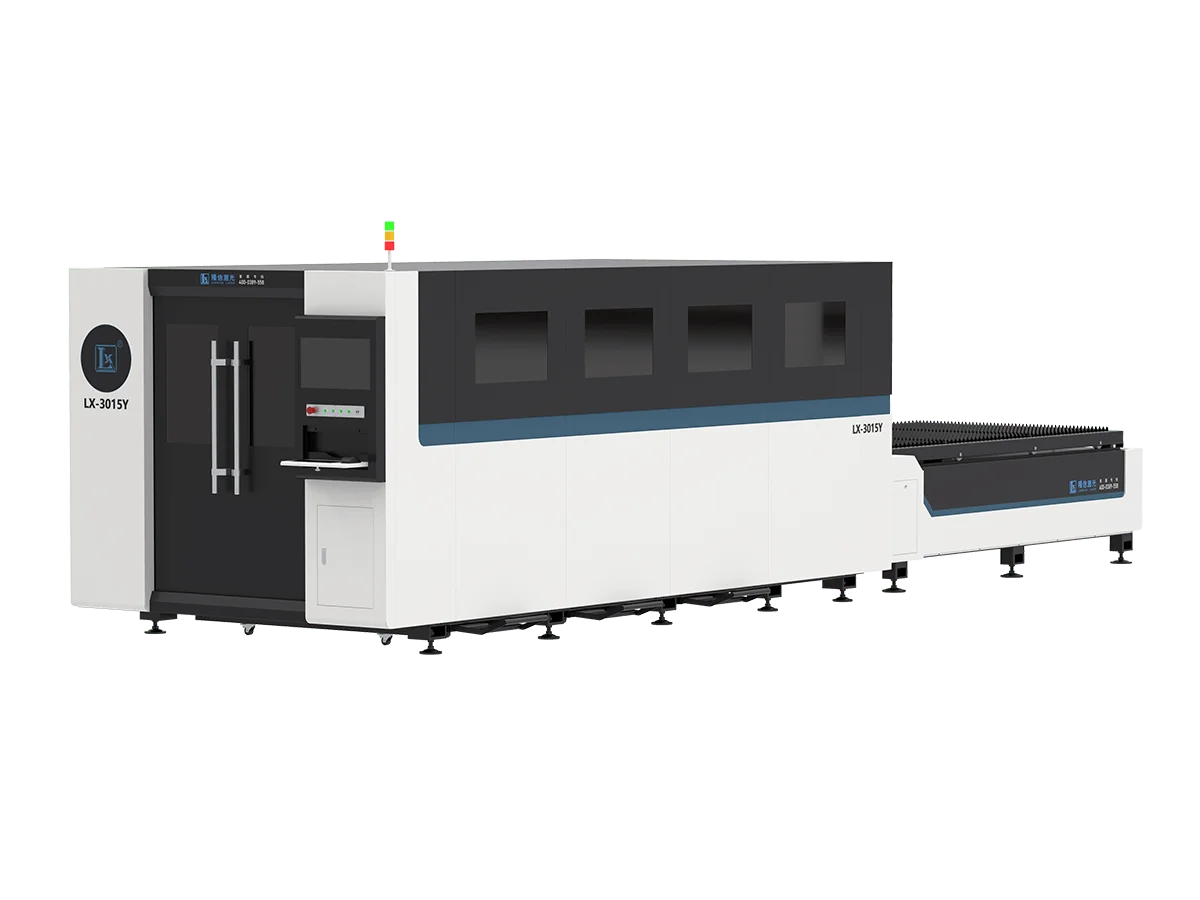

Sheet laser cutting machine

LX-3015Y

Video

Technical Parameters

- Model:

- Laser power:

- Working sheet

- X-Axis Travel

- Y-Axis Travel

- Z-Axis Travel

- XY motion accuracy

- Repeat Position Angle

- Working speed

- Acceleration

- Power demand

- Machine weight

- Apparent size

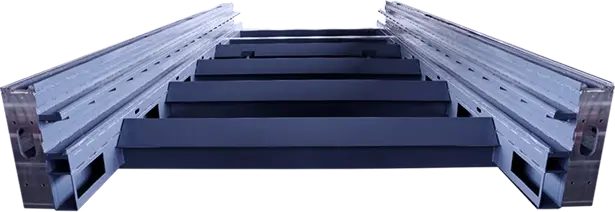

RAGID AND STABLE MACHINE BED

- Stress-relieved frame treated at 600°C, ensuring stability and preventing deformation, allowing it to operate reliably for 20 years.

- Heavy-duty machine bed with thicker materials, guaranteeing stability and vibration reduction during high-speed cutting operations.

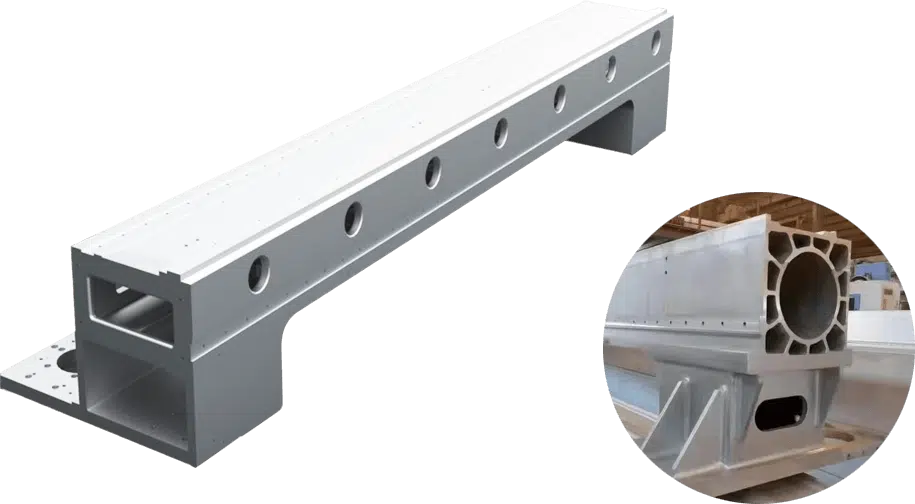

CAST ALUMINUM BEAM

- The machine utilizes a cast aluminum beam known for its excellent rigidity, high strength, and lightweight properties.

- Weighing only half as much as traditional cast iron beams, it enables fast and efficient operations.

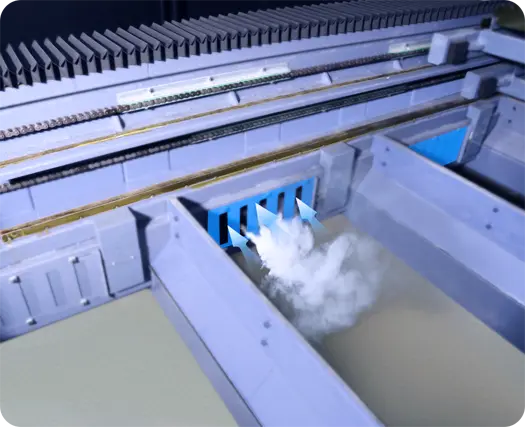

ZONED VENTILATION SYSTEM

- Patented design, time-sharing, zoning, segmented dust extraction structure.

- Pipeline air volume through special design, professional wind speed instrument detection.

- For truly smoke-free cutting in the cutting area.

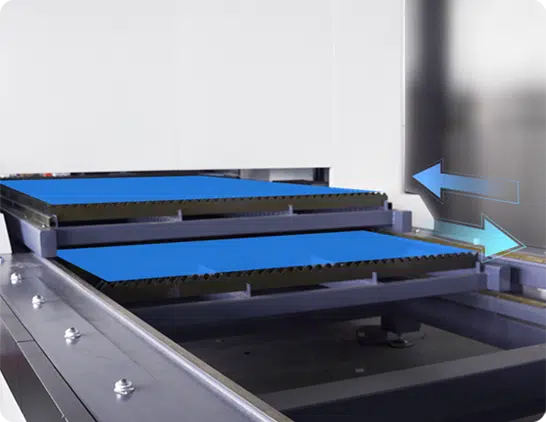

DUAL-DRIVE EXCHANGE WORKTABLE

Equipped with a dual-drive exchange worktable, enabling seamless transition and quick exchange between two different sheets. This feature maximizes efficiency and productivity.

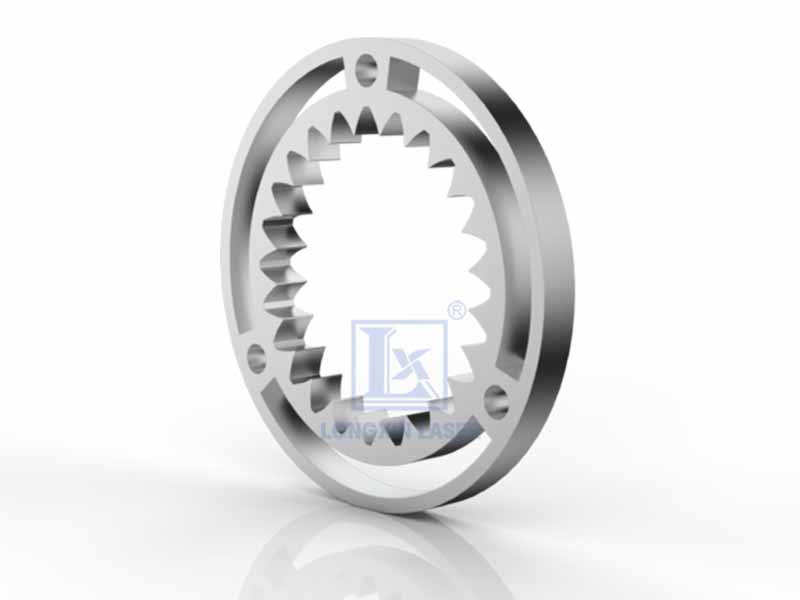

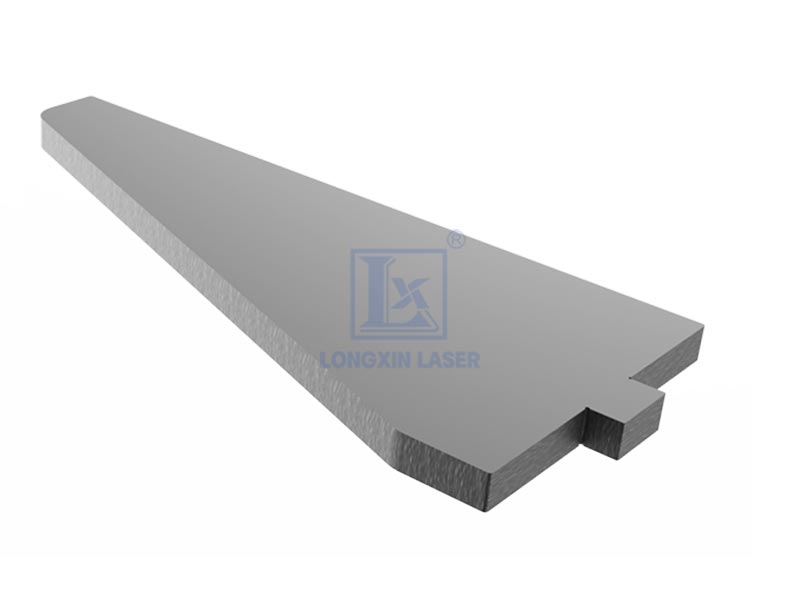

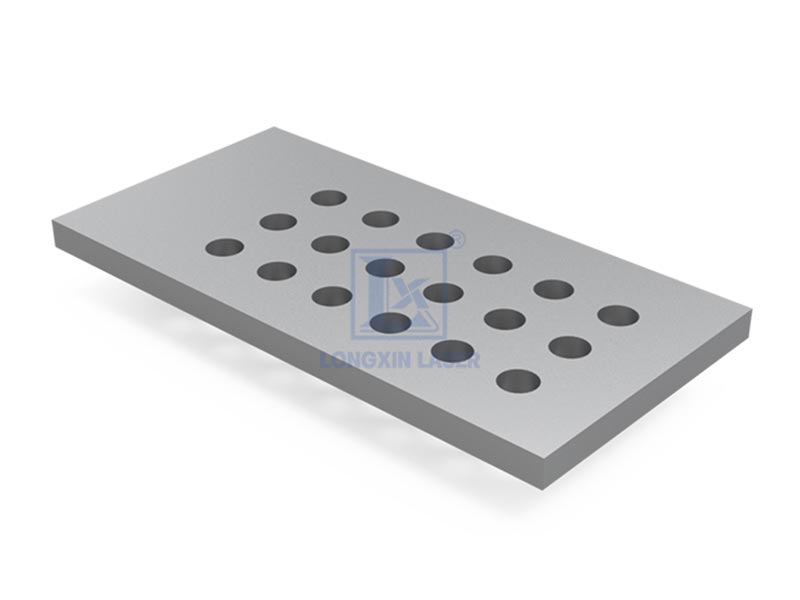

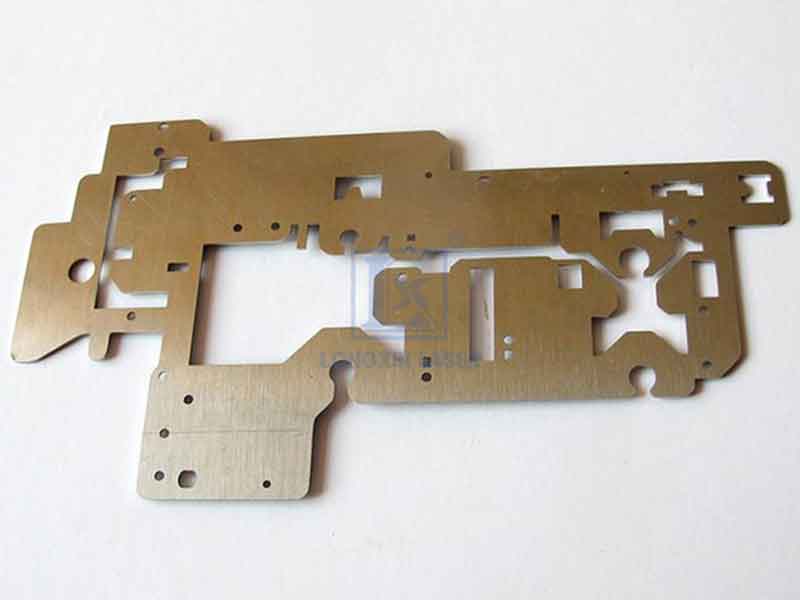

Cutting Samples

Customer Case

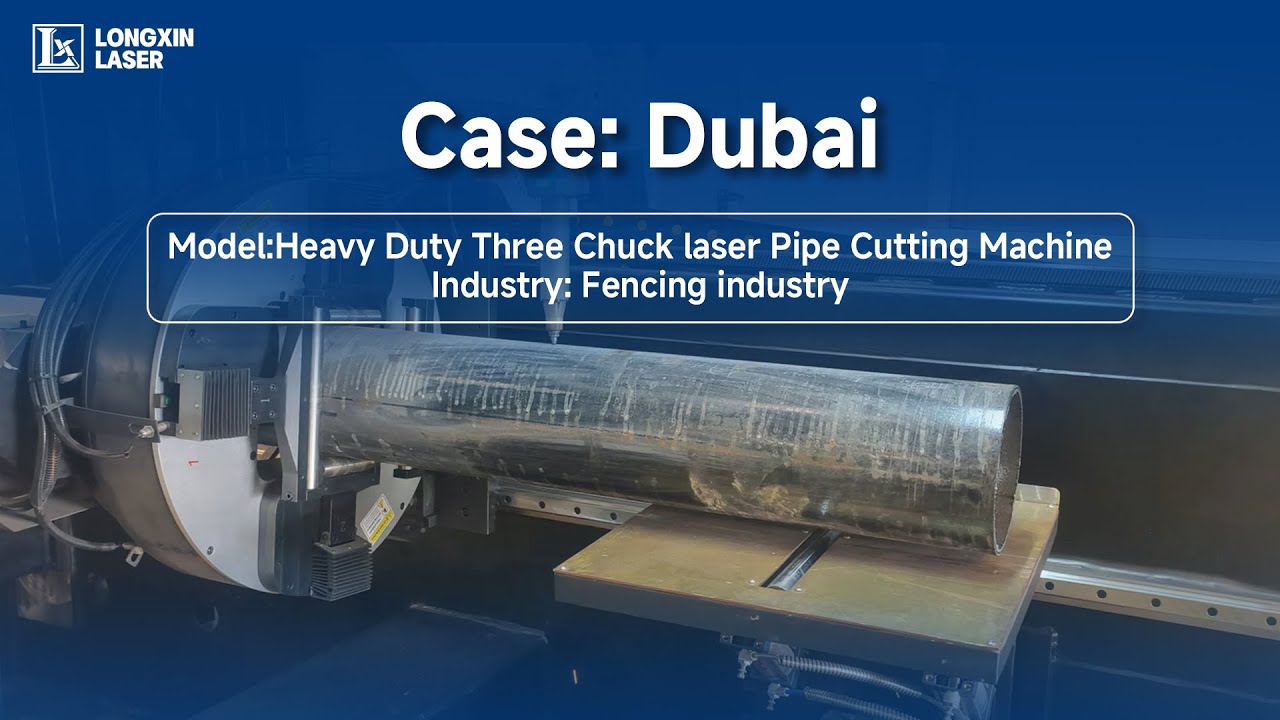

Customer Case: Dubai – High-Power Tube Laser Cutting for the Fencing Industry

Automated High‑Speed Tube Cutting & Chamfering in Türkiye

Longxin Laser Pipe Cutting Machine K9max Helps Indonesia’s Metal Pipe Industry Upgrade Automation

Racing Ahead: Transforming Bracket Manufacturing – Longxin laser

Longxin laser tube cutting machine helps Turkish customers complete furniture production

Streamlining Automotive Parts Production with Longxin Laser Technology

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Order Process for Laser Cutting Equipment

Related Products

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.