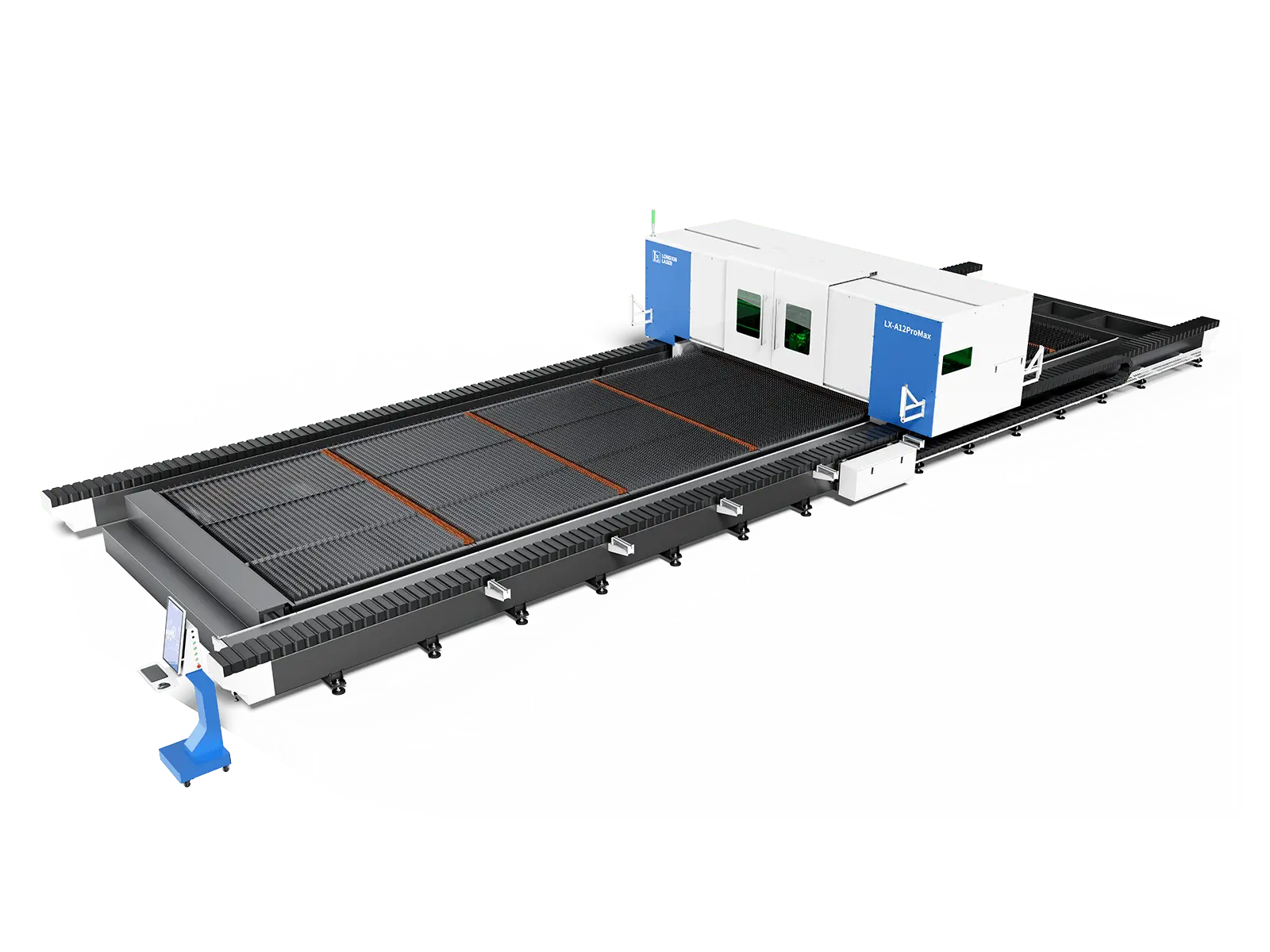

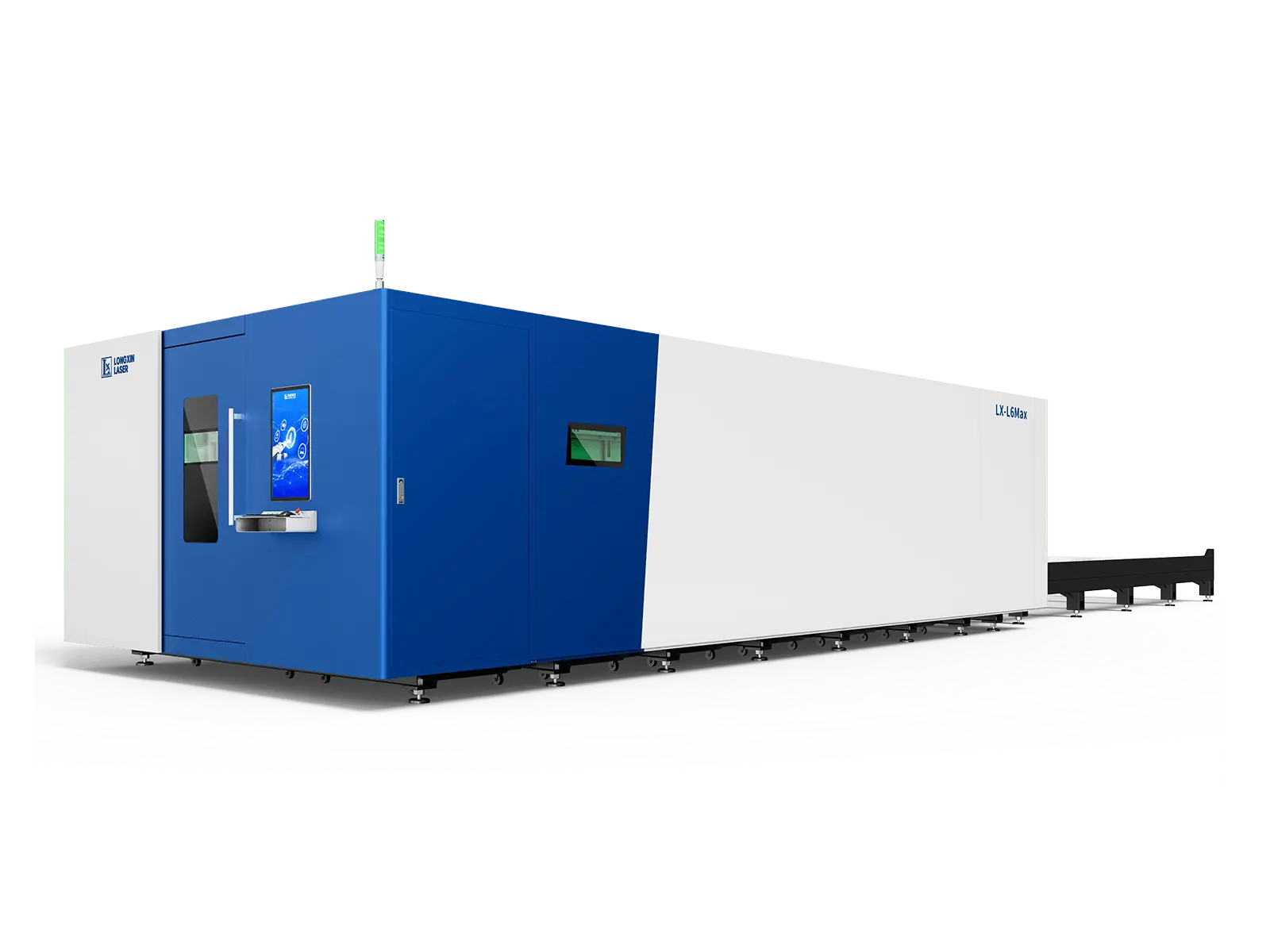

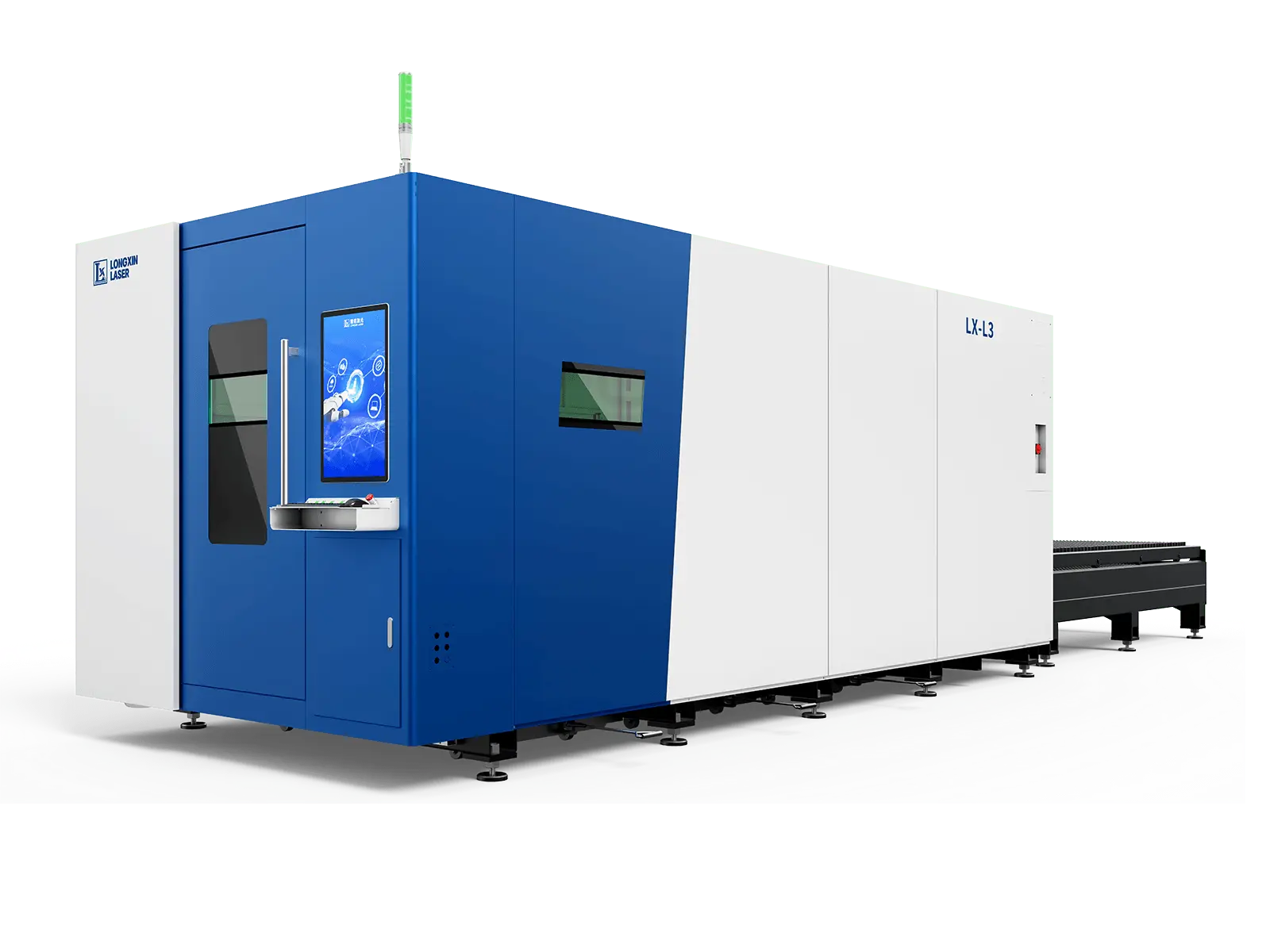

Single-Platform Fiber Laser Cutting Machine

LX-G4

- Unmatched Dynamic Performance: High-performance bus servo system delivers industry-leading acceleration and precision, outpacing traditional setups by 30%.

- Aerospace-Grade Lightweight Beam: Heat-treated aluminum crossbeam boosts cutting speed 20%+ while maintaining heavy-duty strength.

- Full-Power Firebrick Insulation: Molded firebricks prevent bed deformation from heat transfer, ensuring reliability in high-output runs.

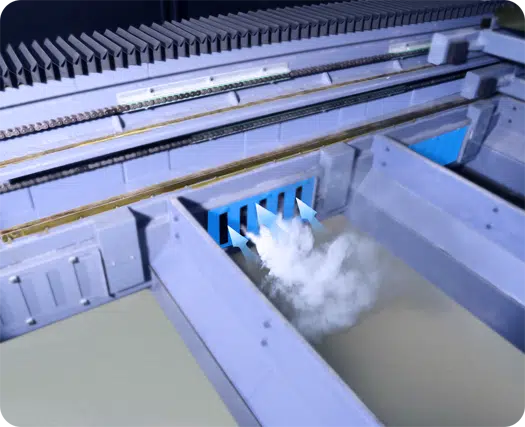

- Adaptive Laser Head Protection: Dynamic shield blocks smoke and debris, extending head life by 30% and slashing replacement costs.

- Zero-Gap Follow-Suction (Optional): Path-tracking dust extraction cuts pollution dramatically, meeting stringent eco-standards.

Product Features

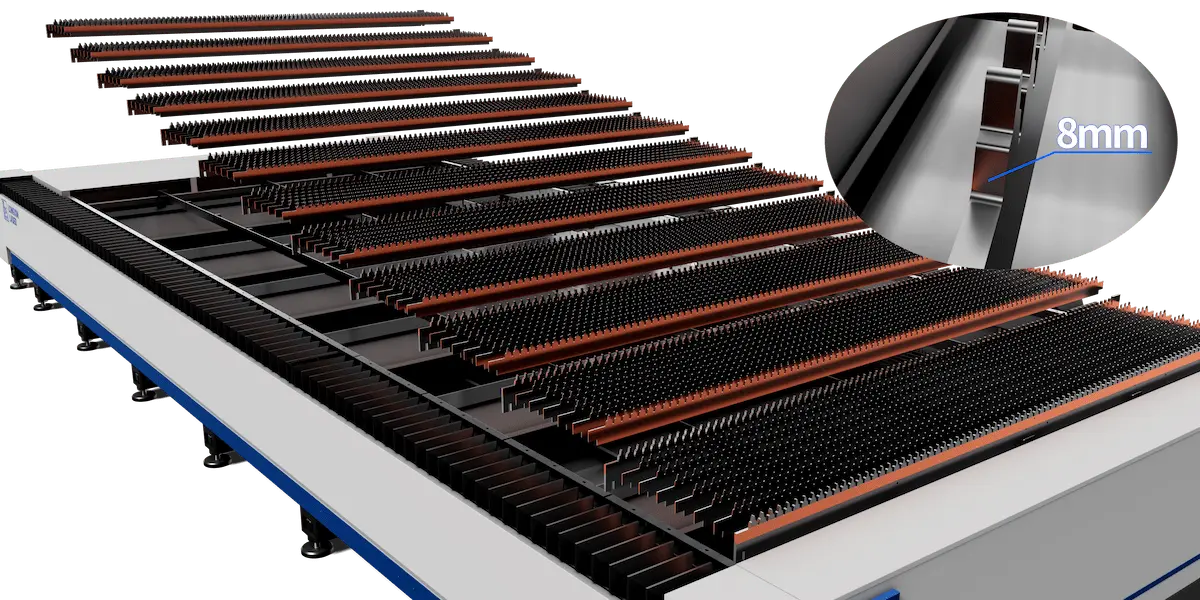

Refractory Bricks for All Power Options

Molded fire-resistant bricks provide excellent thermal insulation, effectively preventing heat transfer and bed deformation during high-power cutting.

High-Strength Aluminum Beam

The beam is integrally machined from aerospace-grade aluminum profiles and reinforced through heat treatment and other processes, delivering high structural strength with a lightweight design for faster cutting.

Heavy-Duty Frame-Type Slats

Featuring a thick 8 mm slat frame design, engineered to support heavy loads.

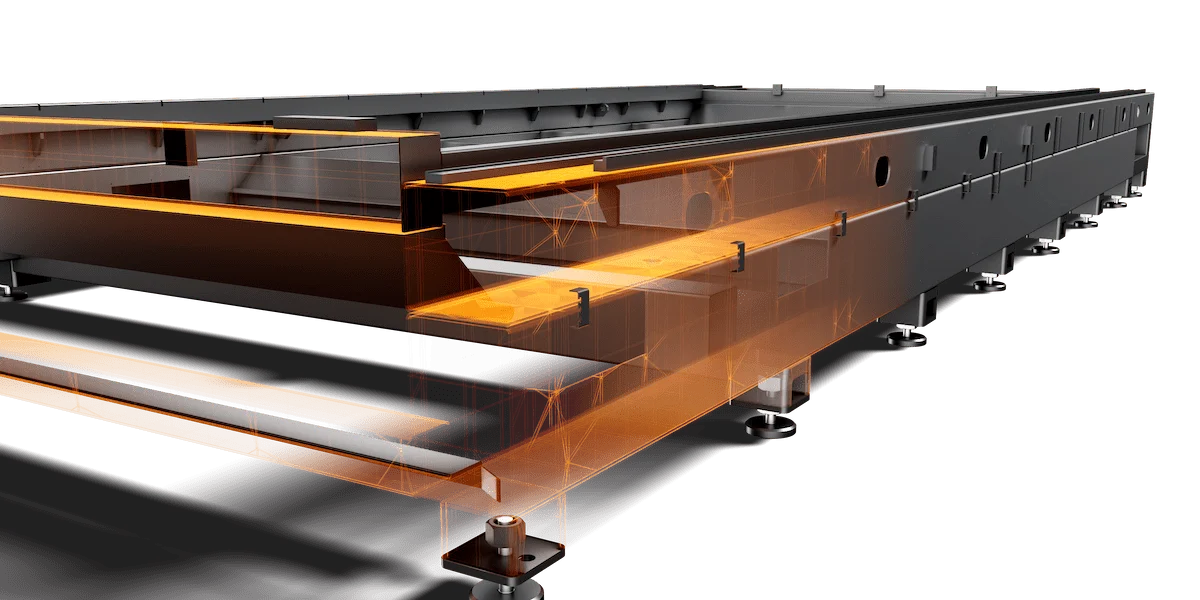

Ragid And Stable Machine Bed

Stress-relieved frame treated at 600°C, ensuring stability and preventing deformation, allowing it to operate reliably for 20 years. Heavy-duty machine bed with thicker materials, guaranteeing stability and vibration reduction during high-speed cutting operations.

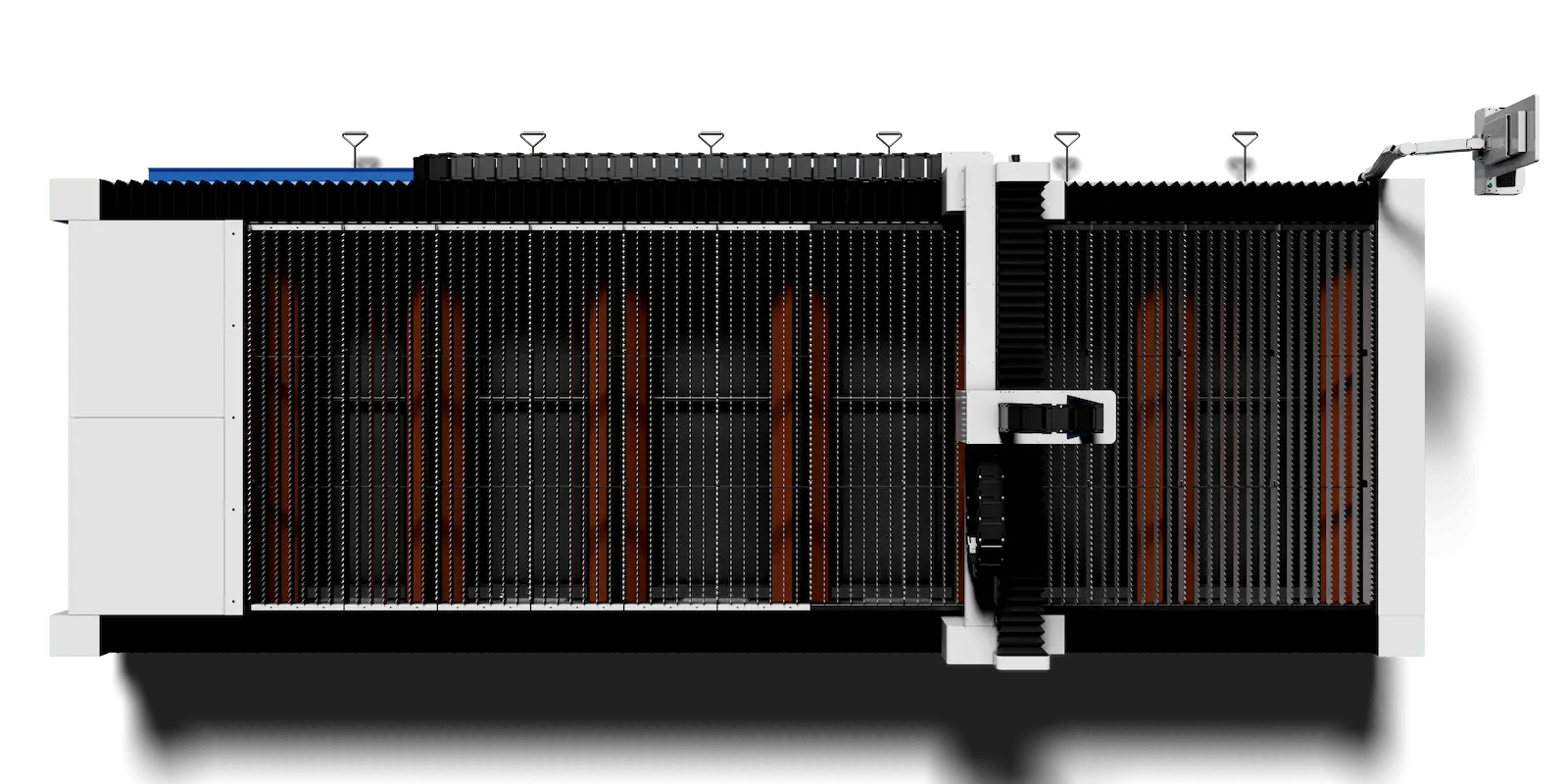

Zoned Ventilation System

Patented design, time-sharing, zoning, segmented dust extraction structure. Pipeline air volume through special design, professional wind speed instrument detection. For truly smoke-free cutting in the cutting area.

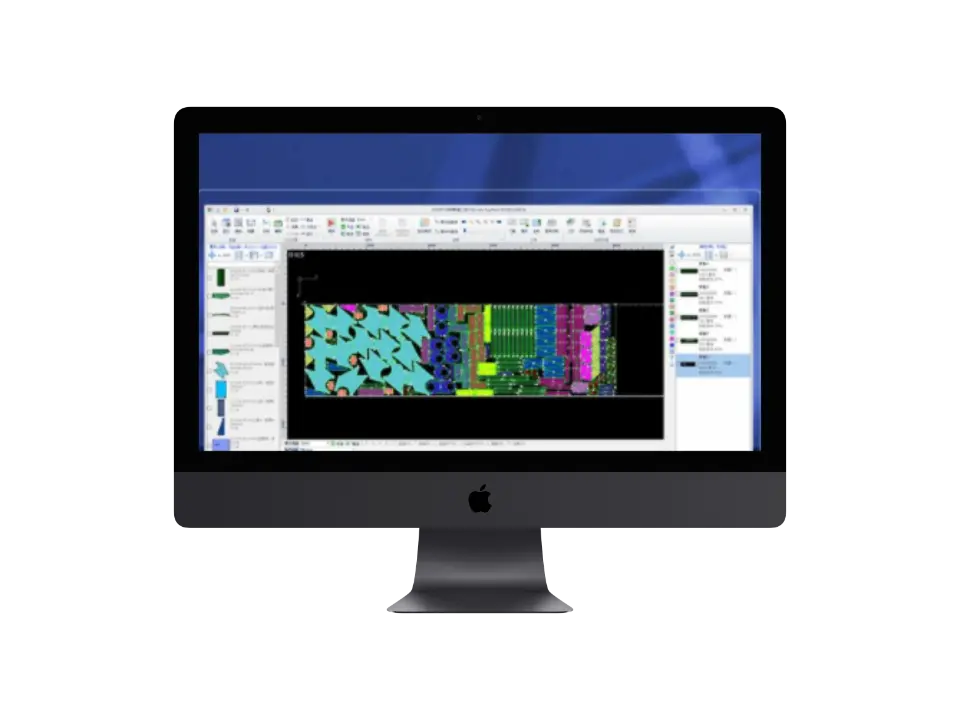

Intelligent Cutting System

The Intelligent Cutting System is a high-end solution designed for fiber laser cutting, offering stability, reliability, easy deployment, and excellent performance. It supports modular, customizable, and automated solutions, featuring functions like multi-level perforation for thick plates, intelligent tool retraction for smooth cuts, automatic edge detection for precise positioning, flying cutting for increased speed, and intelligent nesting to reduce material waste. This makes it one of the most advanced and efficient laser cutting systems available.

Technical Parameters

- Model:

- Laser power:

- Working sheet

- X-Axis Travel

- Y-Axis Travel

- Z-Axis Travel

- XY motion accuracy

- Repeat Position Angle

- Working speed

- Acceleration

- Power demand

- Machine weight

- Apparent size

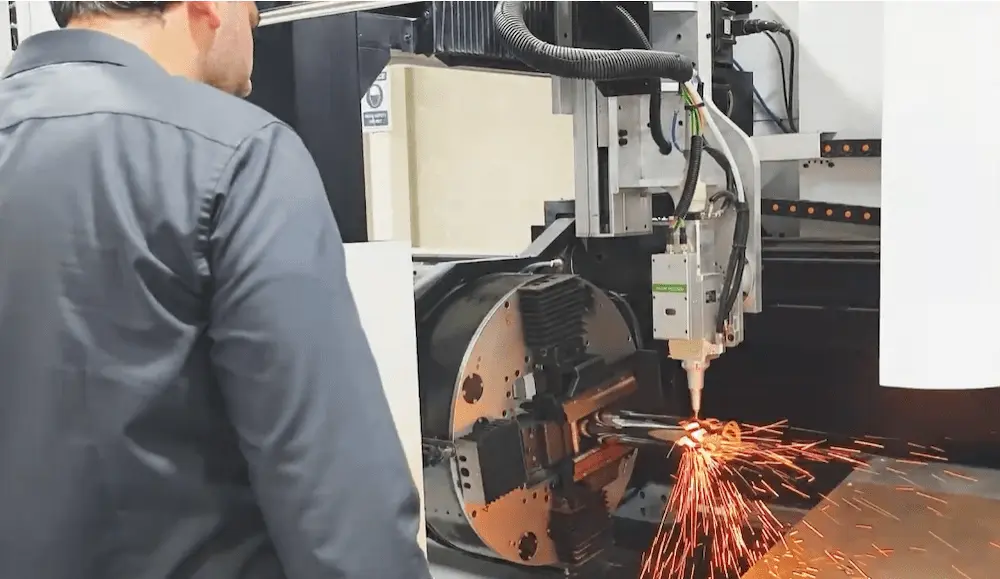

Cutting Samples

Customer Cases

Korea’s Leading Steel Structure Manufacturer Upgrades Production with Longxin Laser LX-T35 Three-Chuck Bevel Tube Cutting Machine

How Longxin LX-K24 3D Laser Tube Cutting Machine Boosted Jinjia Building Materials’ Productivity by 20%

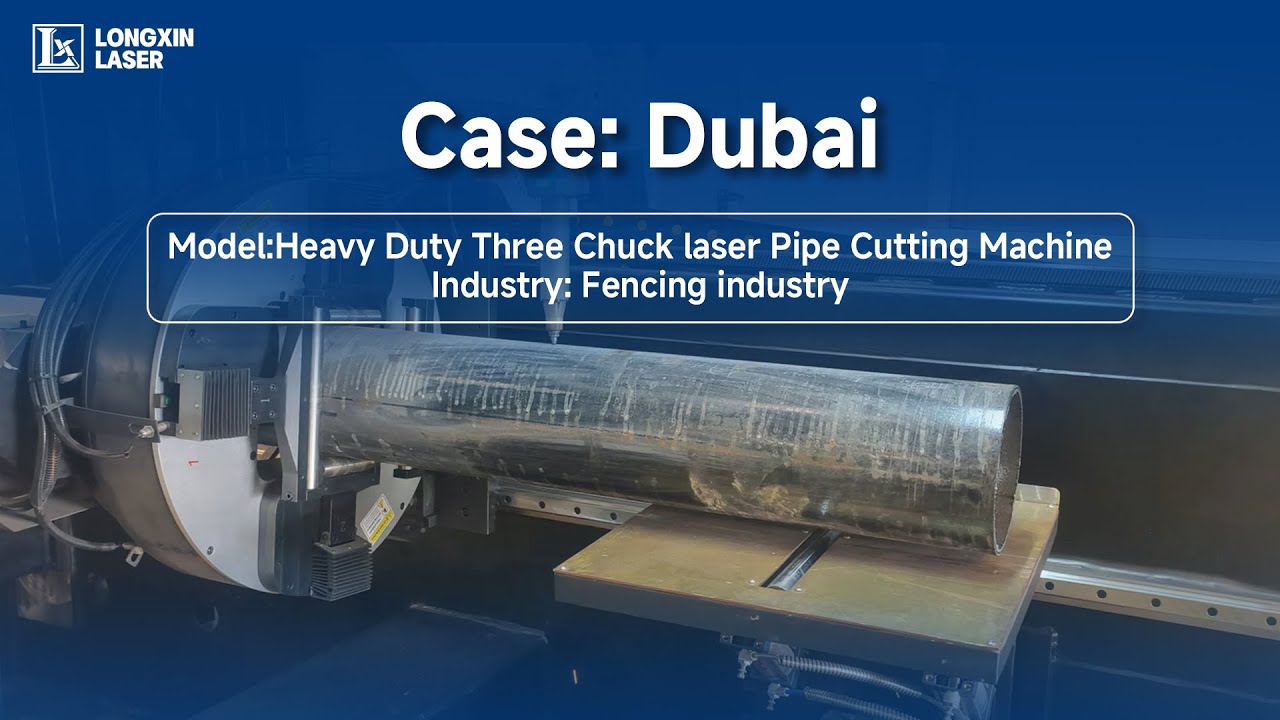

Dubai Construction Client Boosts Productivity with Longxin LX-K28 Three-Chuck Laser Tube Cutting Machine

Longxin Laser Machine LX-K6 in South Africa

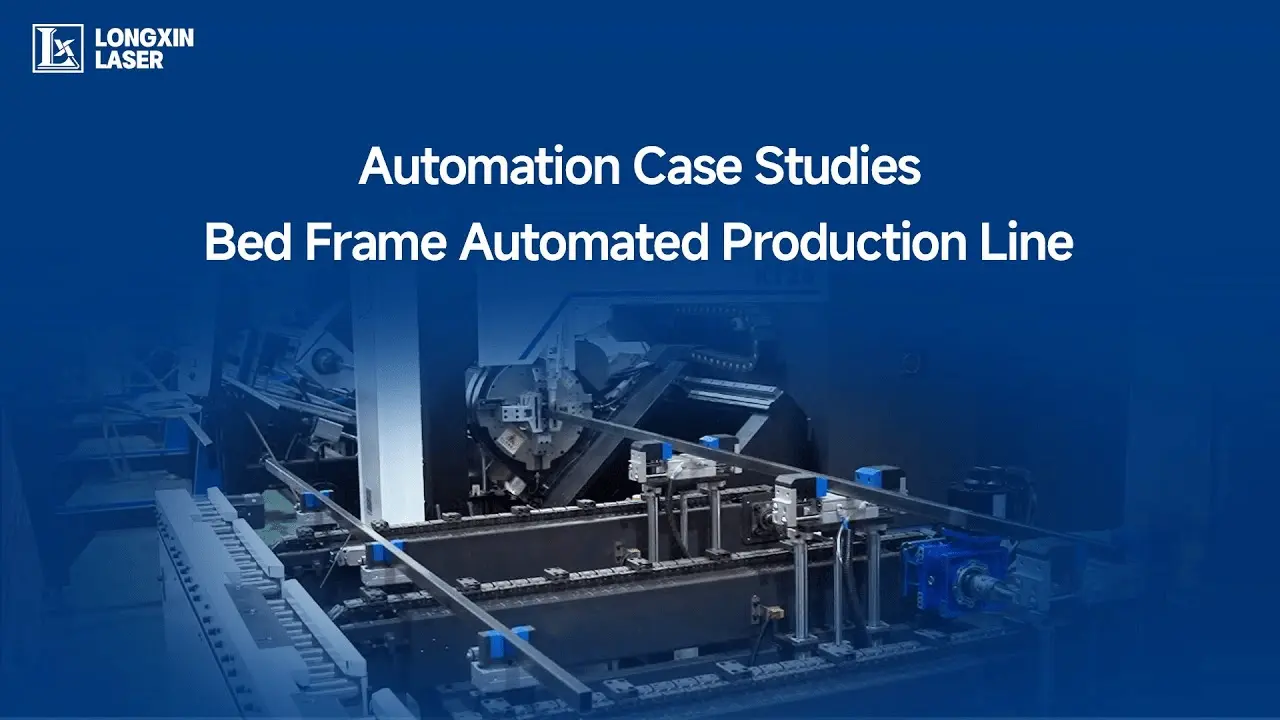

Bed frame laser pipe cutting machine production line case study

Customer Case: Dubai – High-Power Tube Laser Cutting for the Fencing Industry

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Related Products

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.