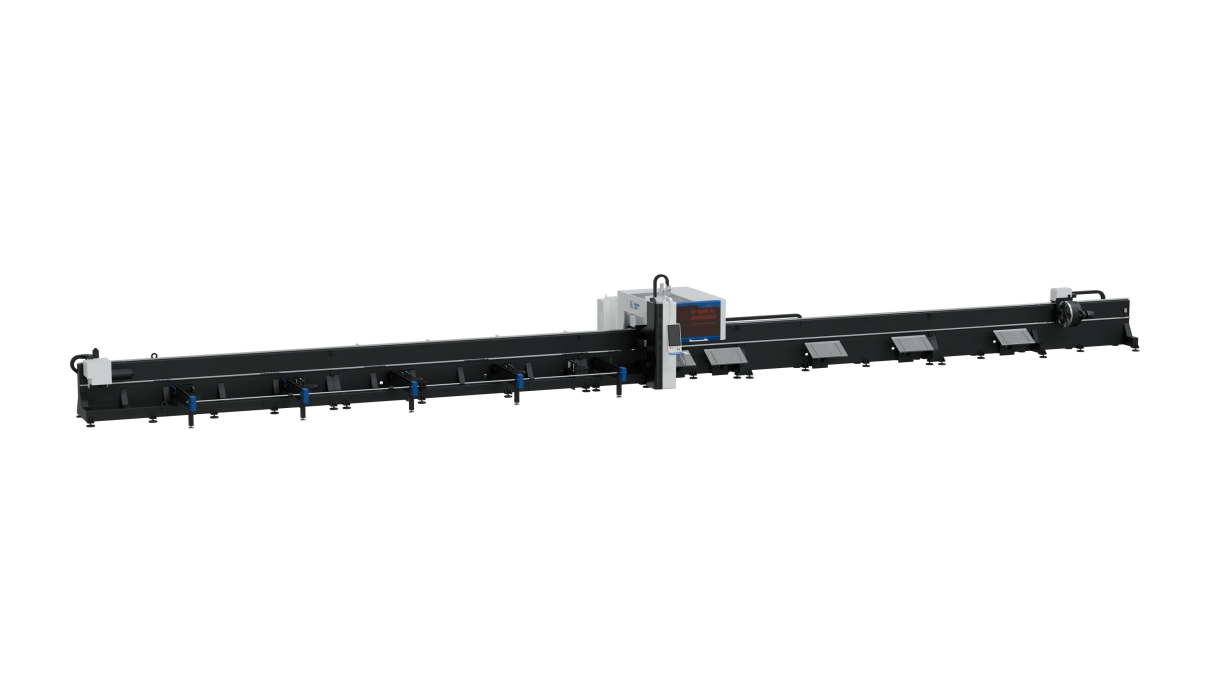

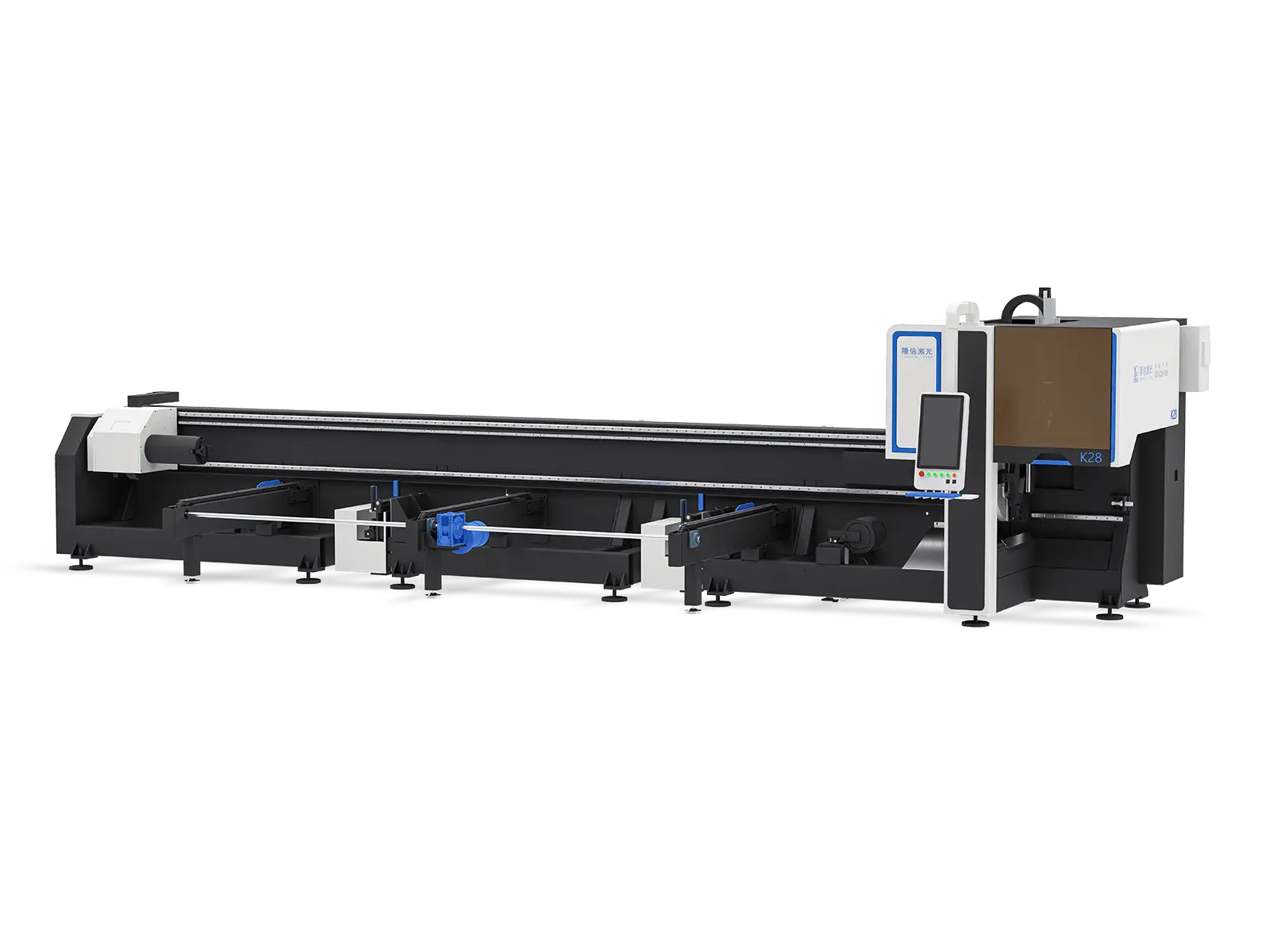

3D laser pipe cutting machine

LX-K28

- Side-mounted chuck, ultra-short tail

- Large processing size, high cost performance

- High production efficiency, stable operation

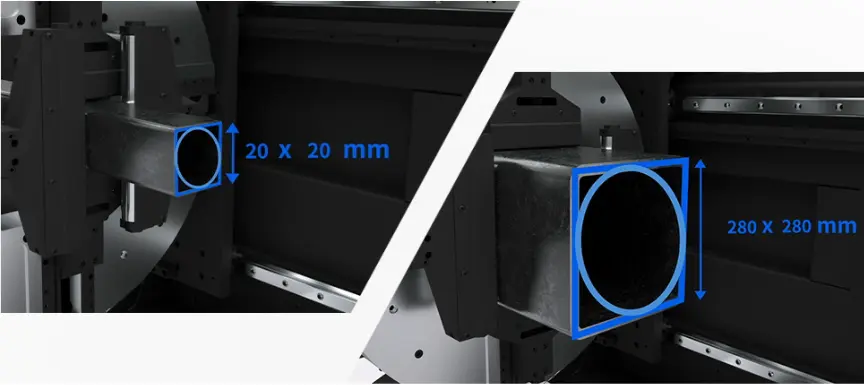

- Processing range: Round tube: ∅20-280mm Square tube: □20*20-280*280mm

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Video

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

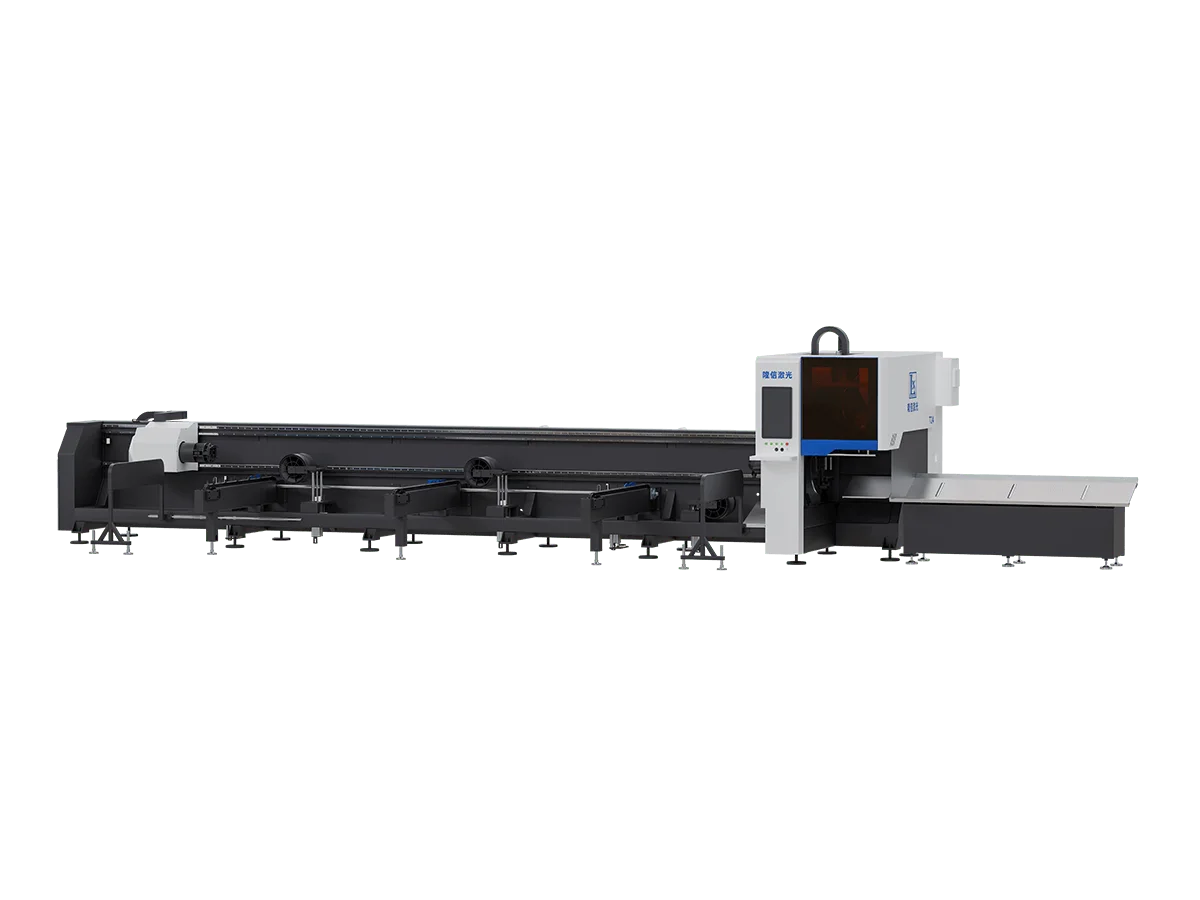

Best choice for large pipes processing

The design of the side-loading lathe enables easy feeding of large diameter pipe materials. It can machine round pipes with diameters ranging from 20-280mm, as well as square pipes with sizes ranging from 20x20mm to 280x280mm.

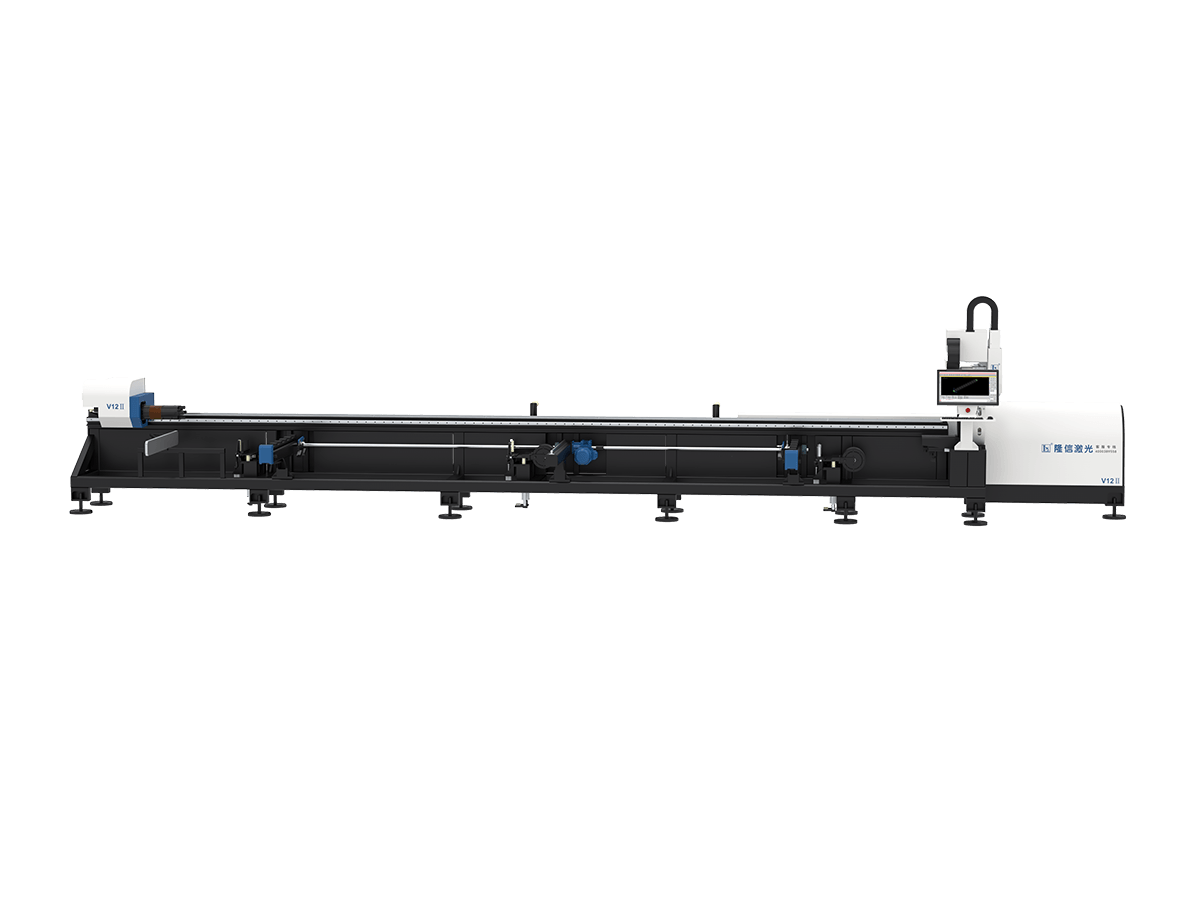

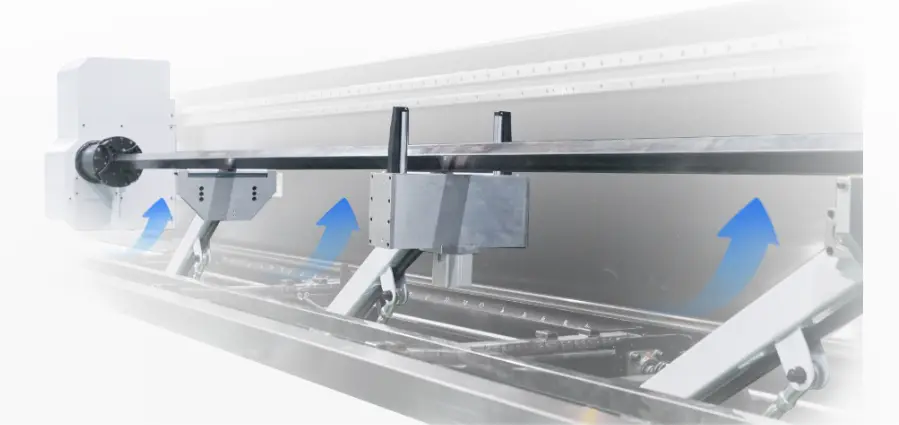

Servo Follow-Up Material Support System

A servo fllow-up support device is used to provide real-time lifting and support for the tubes during processing, significantly enhancing cutting stability and precision.

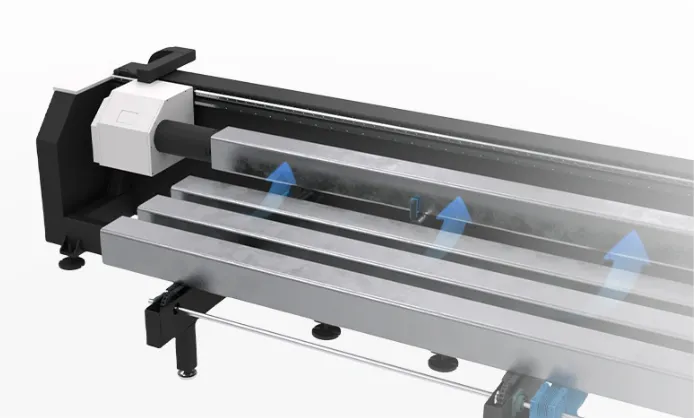

Fully automated loading via array configuration

It can automatically load 4 large pipe materials at one time, making the operation fully automatic, easy and worry-free

Intelligent CNC system specifically designed for pipe cutting

The system features a visual operation screen, easy parameter adjustments, and a wide range of functions. It supports multi-level perforation, intelligent tool retraction, automatic edge detection, and intelligent nesting, among other customizable features.