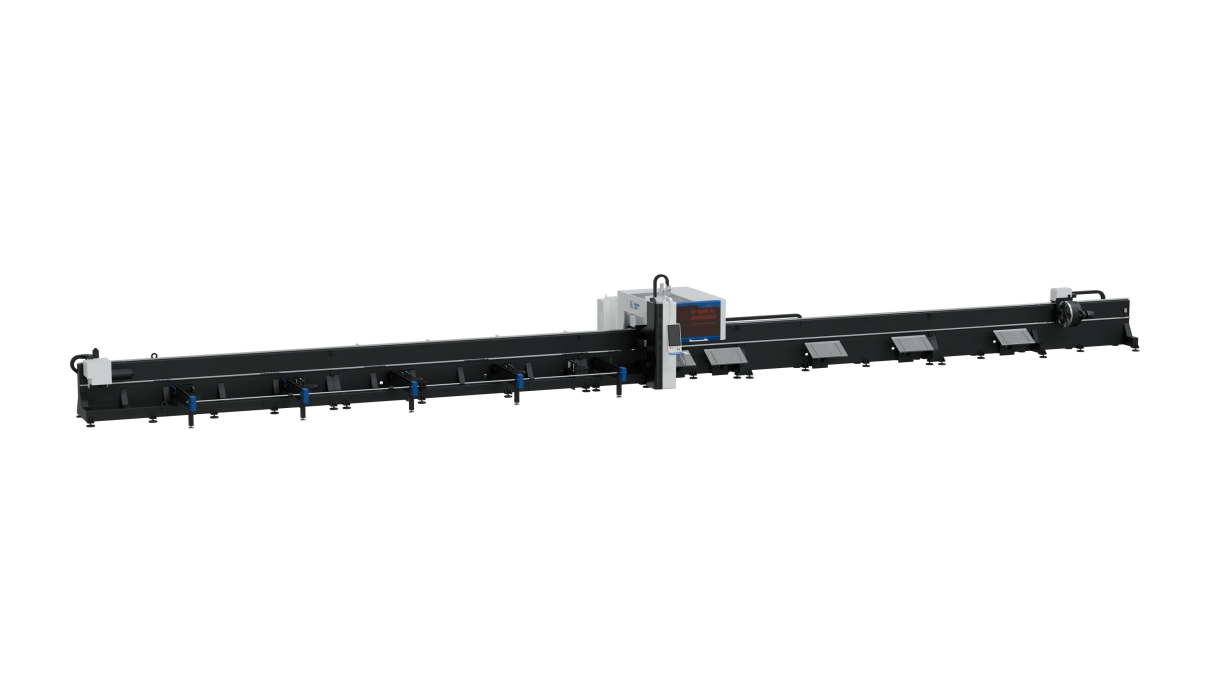

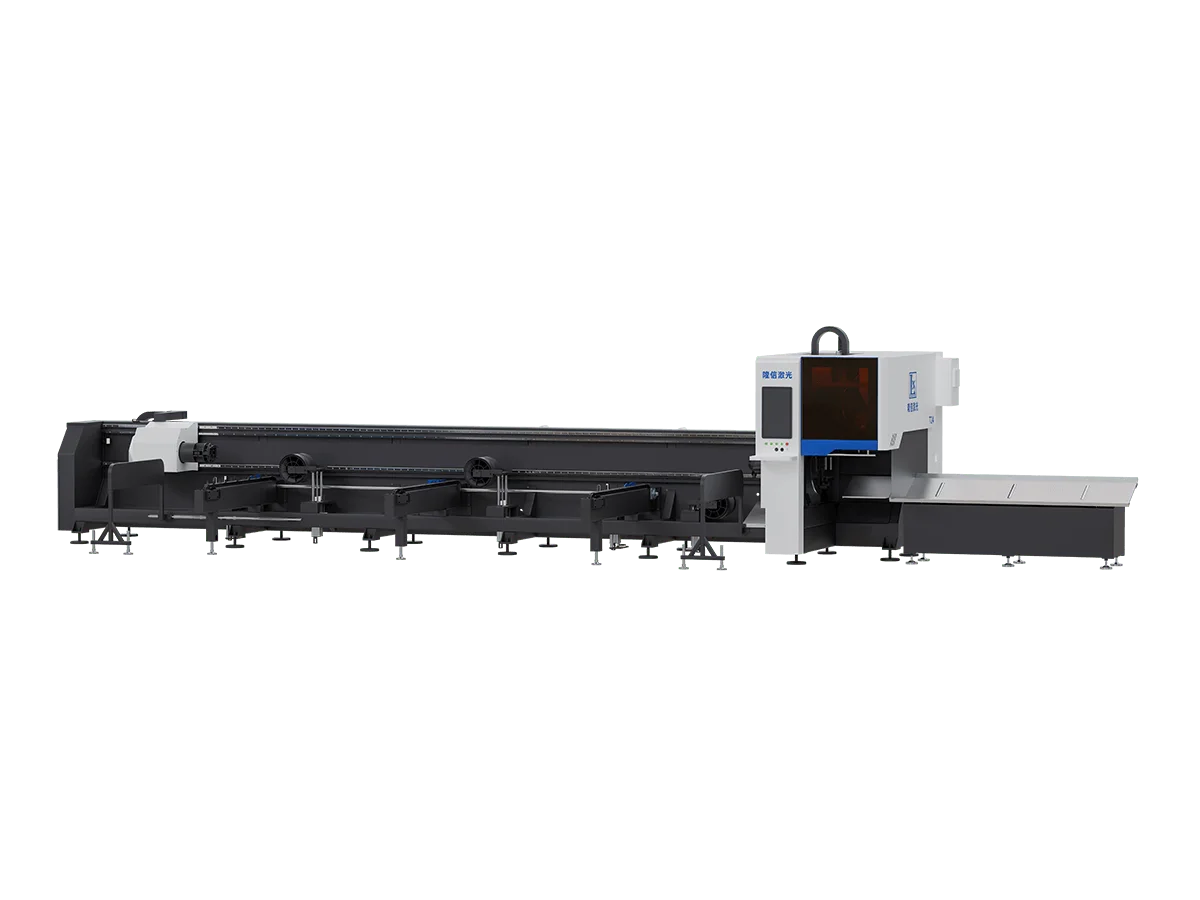

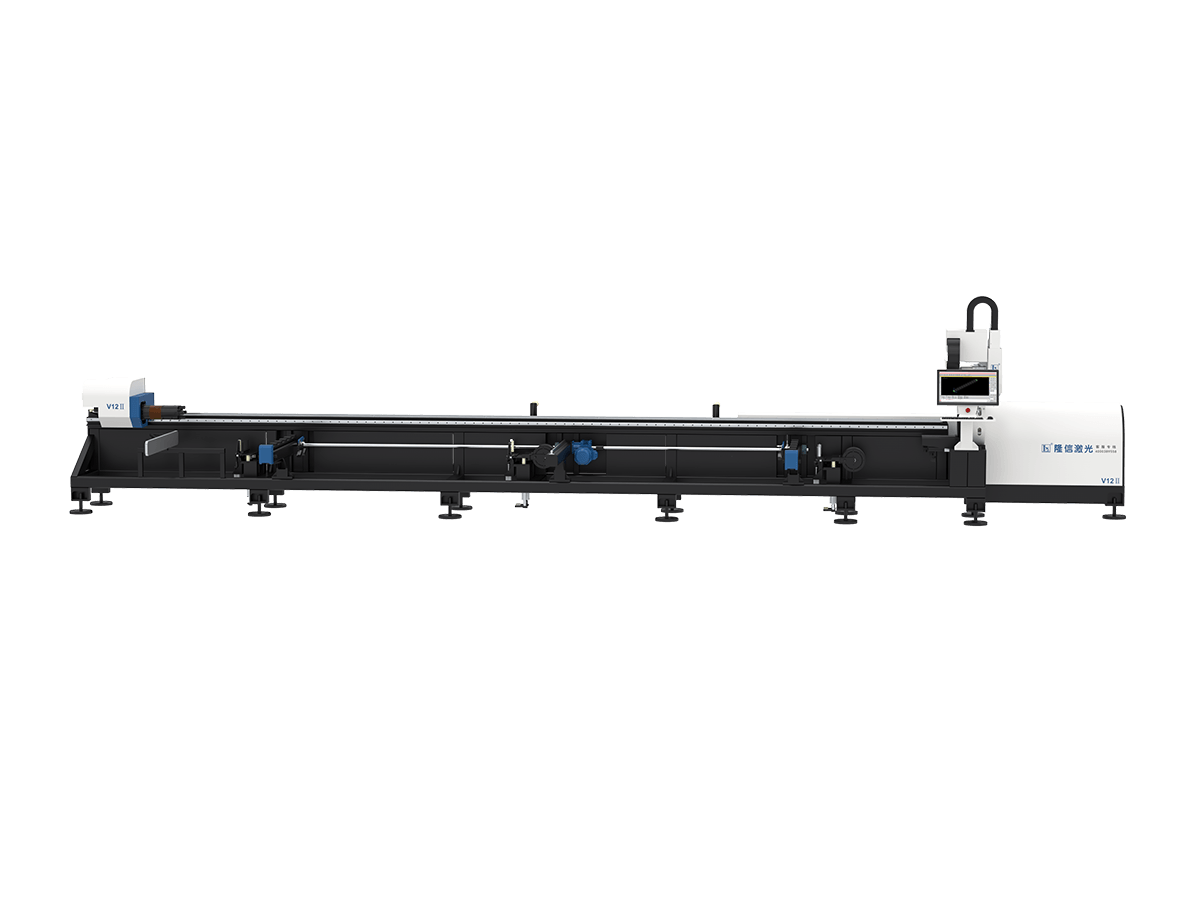

Fullly-covered cnc laser tube cutting machine

LX-K6

- Medium and high configuration, the first choice for beginners;

- Cutting pipe diameter range: ∅ 15mm-85mm / ▢ 15mmx15mm-diagonal less than 85mm

- Annealing bed, high stability

- Automatic distinction between head and tail materials

- Automatic identification of pipe direction, smoother feeding

- Automatic material protection function to improve cutting efficiency

- Follow-up material support function

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Video

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

1.5G High Speed Storm Cutting

High Speed + Storm Cutting Φ20 thick 1.05 stainless steel tube, 0.8S/piece, 8h/day, 36000 pieces/day; For 15X15-60X60MM round pipe, square pipe cutting

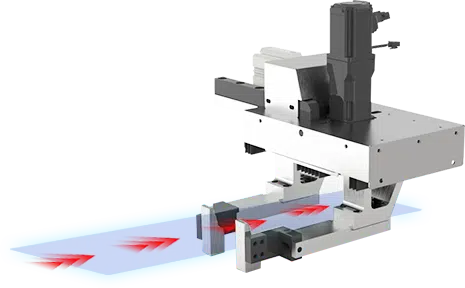

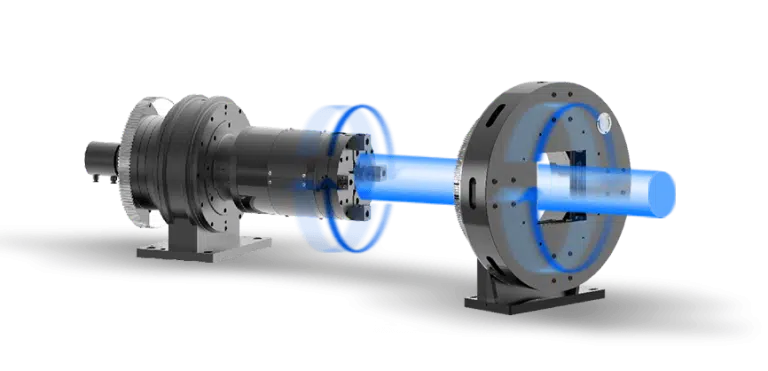

Automatic Pneumatic Chuck

Fully automatic pneumatic chuck, stable and efficient. One key to open the clamp, automatic centering, speed is 3 times of electric chuck. Pneumatic open clamp, large clamping force and adjustable strength, heavy tubes do not loosen and do not slip, light tubes do not deform, to ensure cutting accuracy.

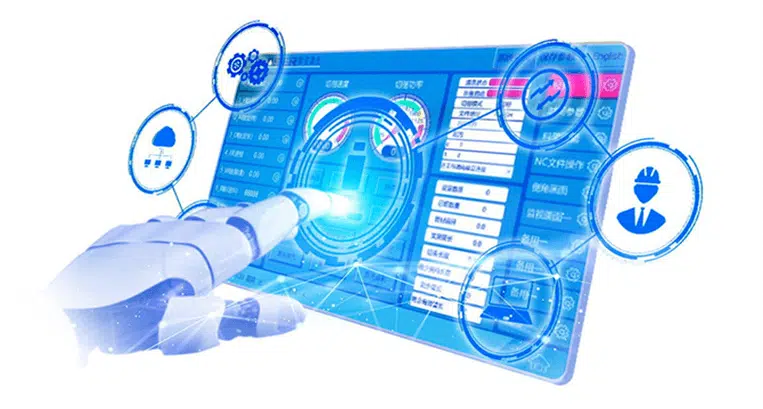

Self-Developed CNC Control System

Deep optimization and ultra-fast response Cooperate with Radan professional graphics nesting software,The perfect combination of speed, function and stability.

Precise clamping and feeding design

High-precision ground rack and pinion drive, automatic recognition of long and short sides of profiles, excellent performance, fast response, and low failure rate.