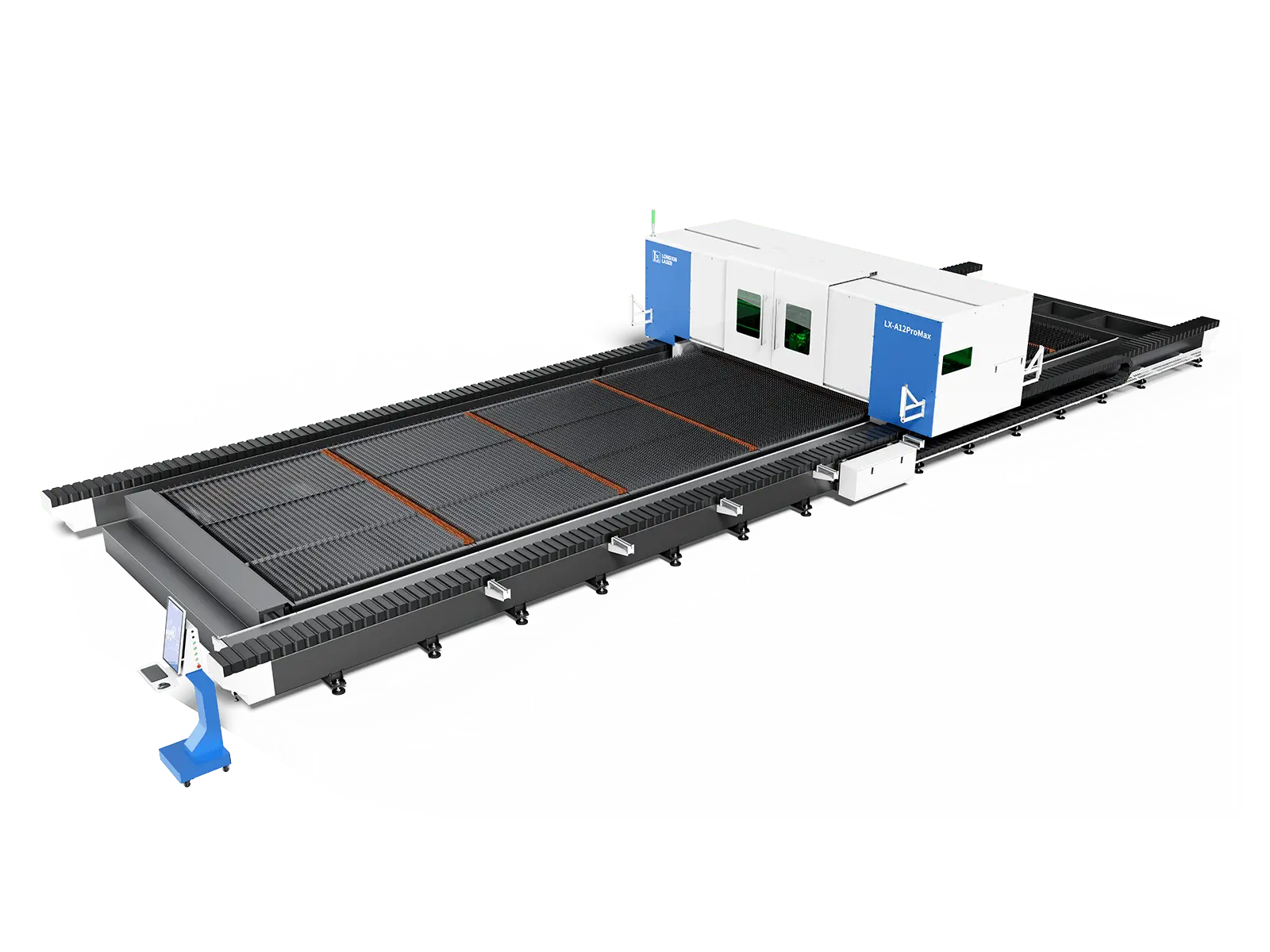

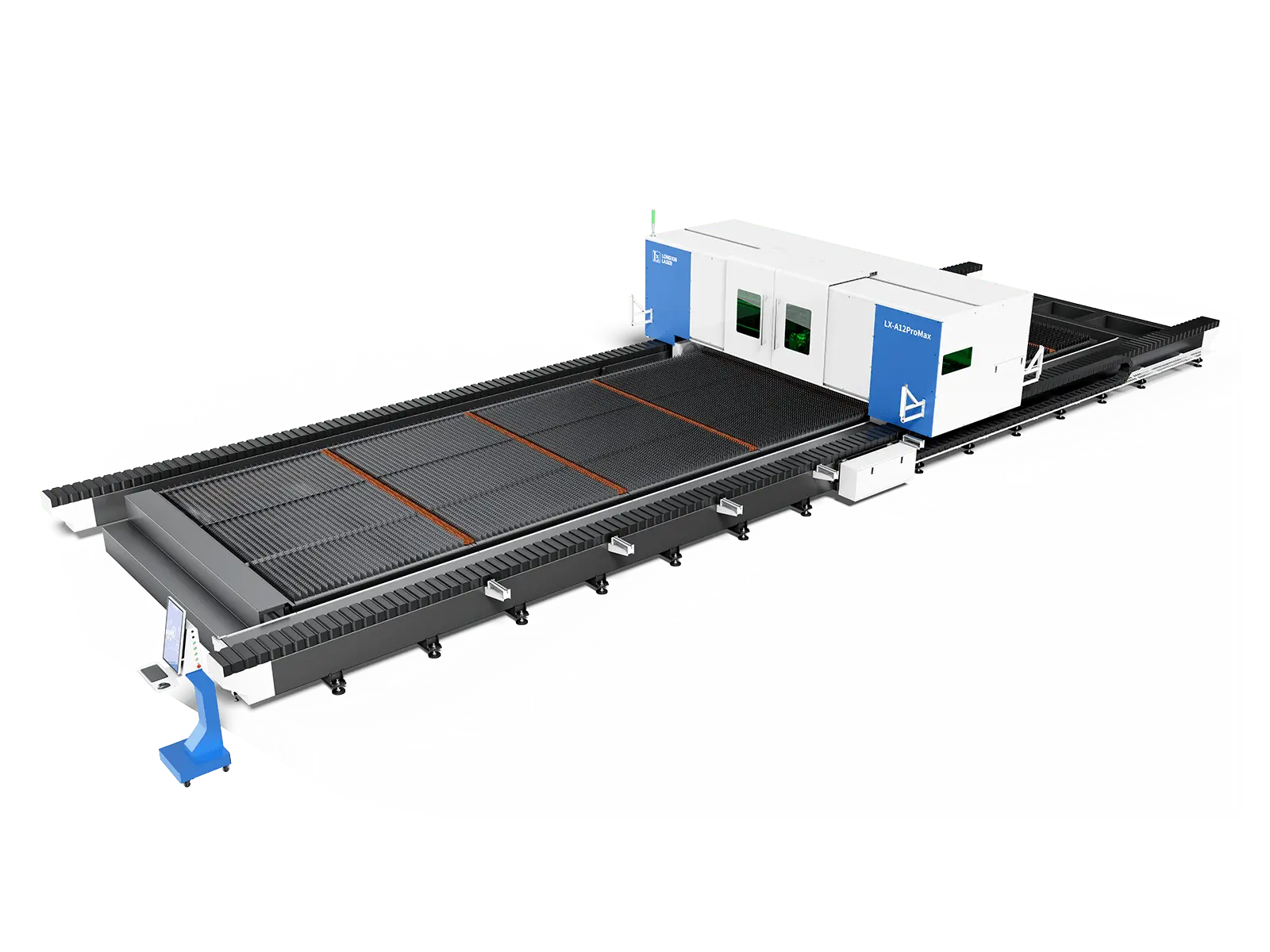

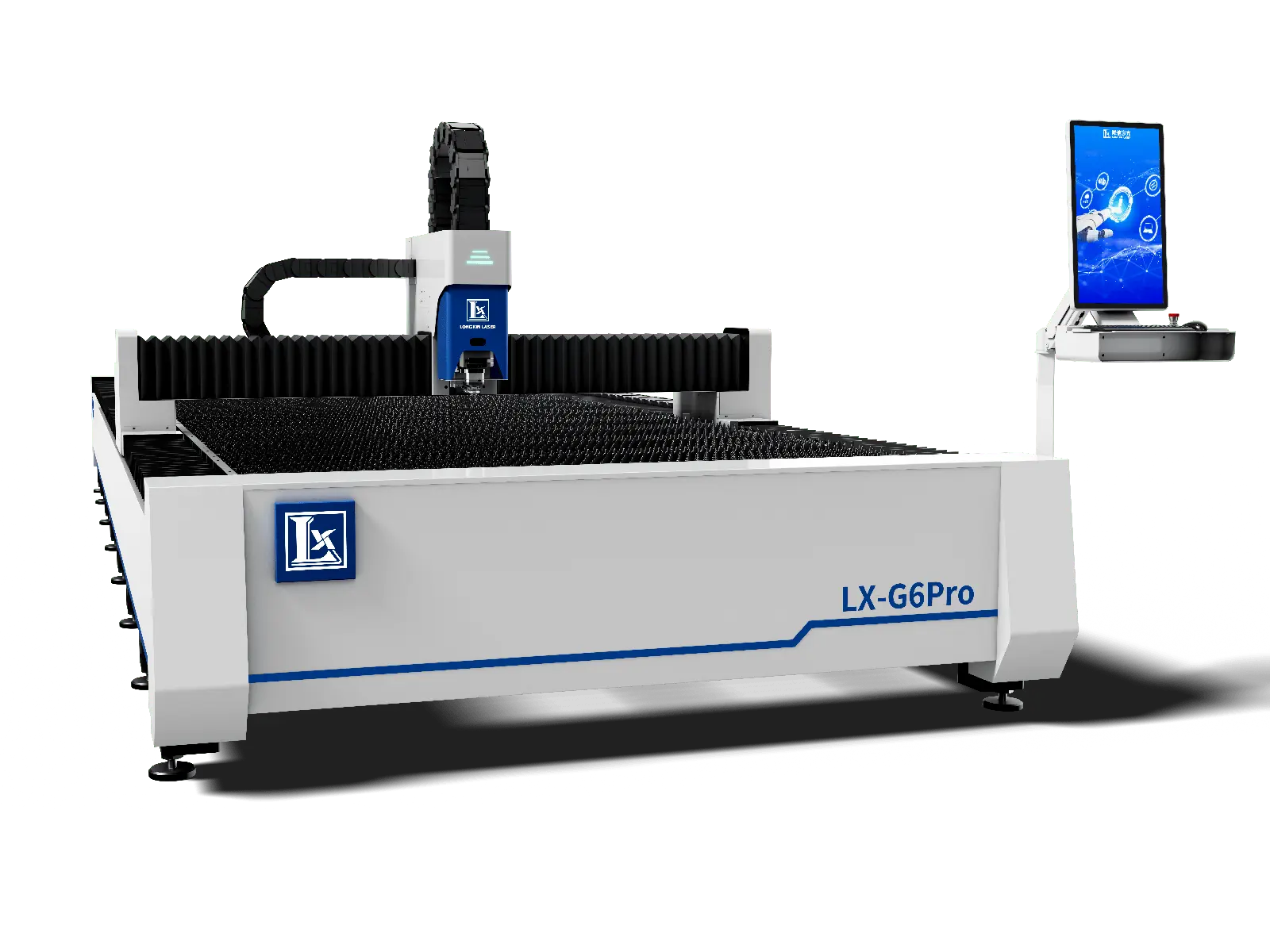

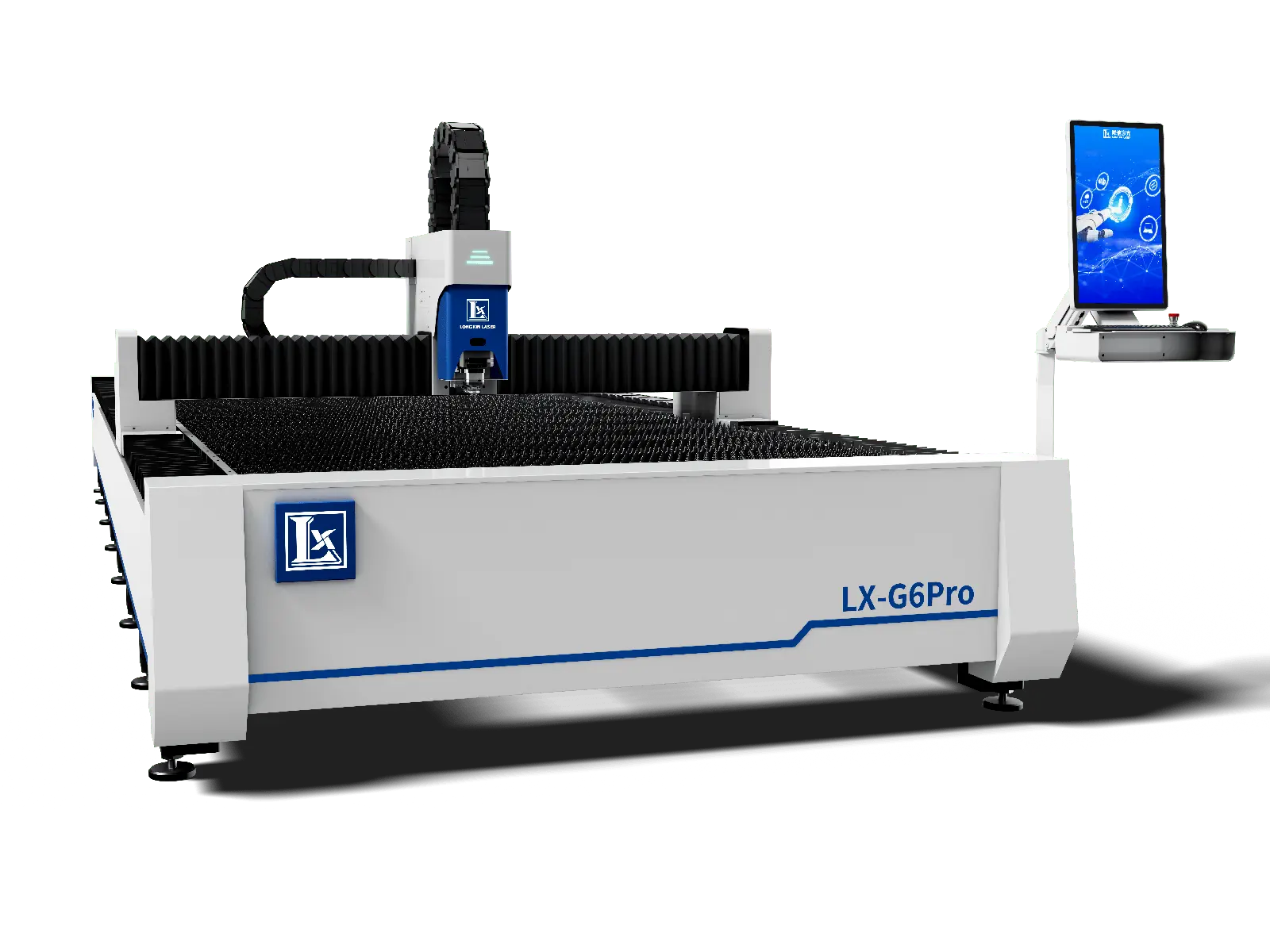

Sheet Metal Laser Cutting Machine

Our sheet metal laser cutting machines are industrial fiber laser systems designed specifically for cutting metal sheets in manufacturing and fabrication. Our machines help you boost production efficiency while minimizing material waste and operating costs.

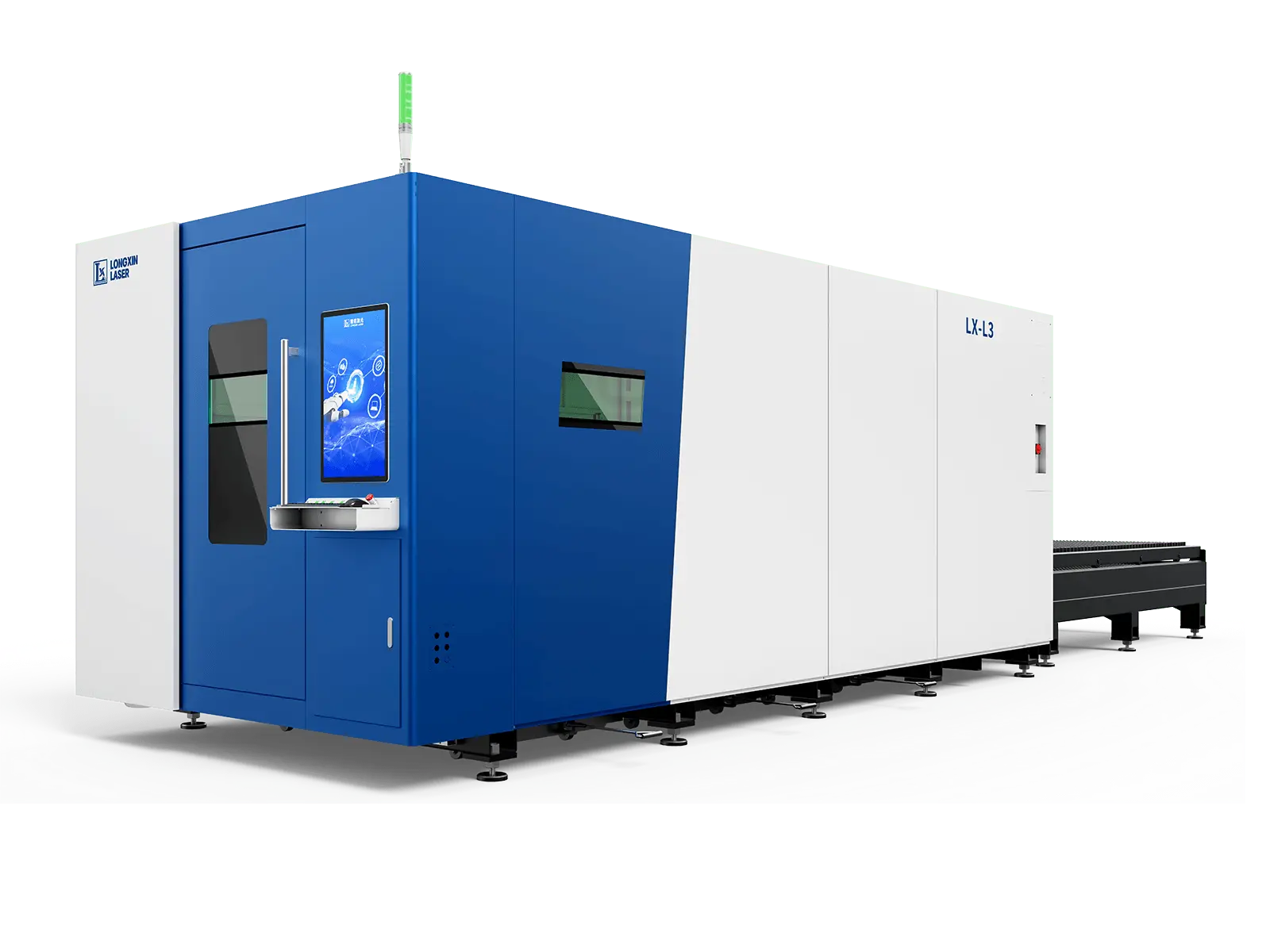

Power: 1500W-20000W

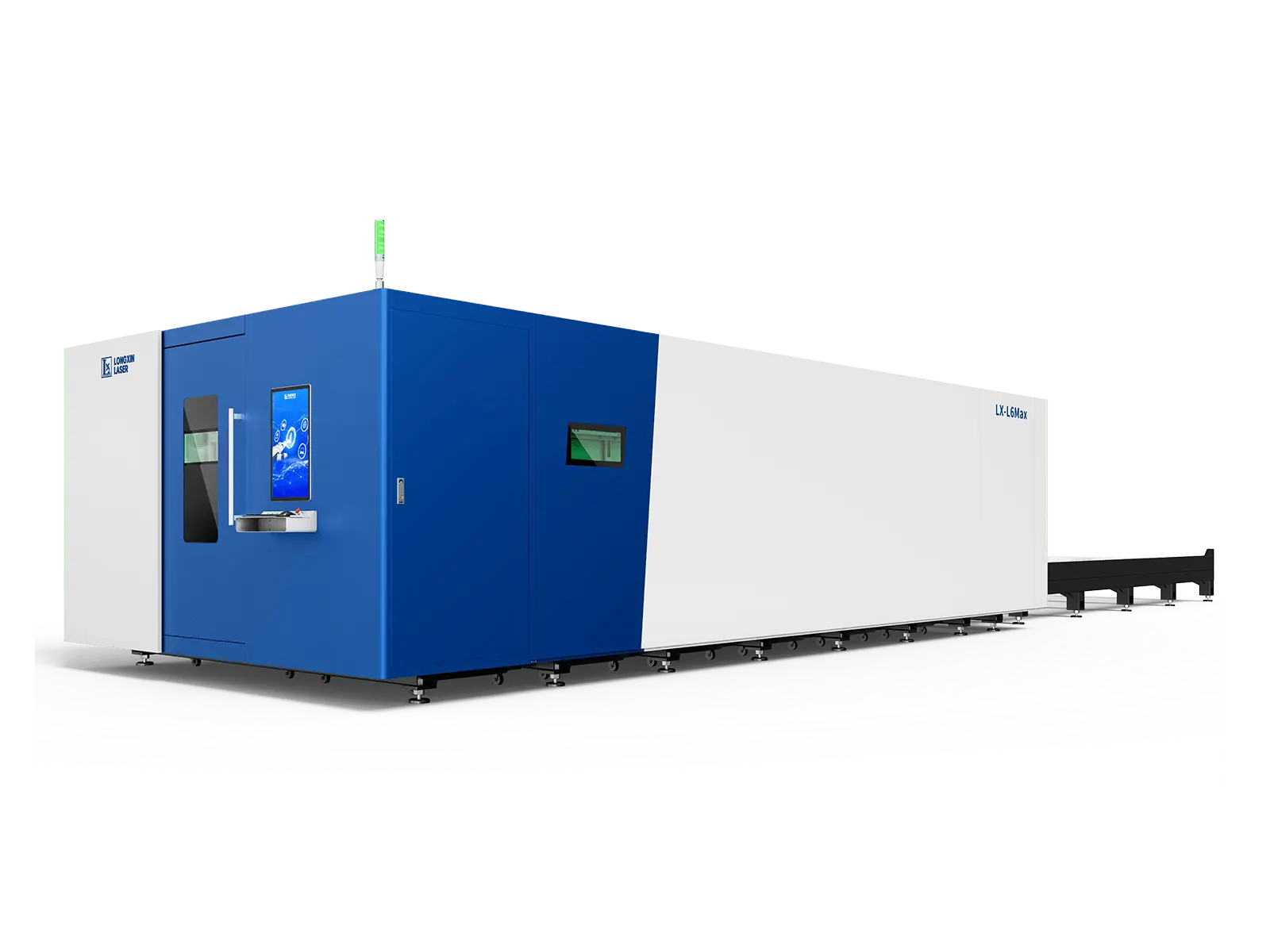

Cutting Area: 3250*12300mm

Power: 1500W-20000W

Cutting Area: 2530*6050mm

Power: 1500W-20000W

Cutting Area: 1530*3050mm

Power: 1500W-20000W

Cutting Area: 2540*6100mm

Power: 1500W-20000W

Cutting Area: 2030*6100mm

Power: 1500W-20000W

Cutting Area: 1530*6100mm

Power: 1500W-20000W

Cutting Area: 2030*4050mm

Power: 1500W-20000W

Cutting Area: 3048*1550mm

Power: ≥30kW

Cutting Area: 12000*3100mm

Customer Case

Why longxin laser?

Cutting-edge technology

Extensive experience

Efficient Production

Custom automation

Customer Support

Smart software

How a metal laser cutting machine works?

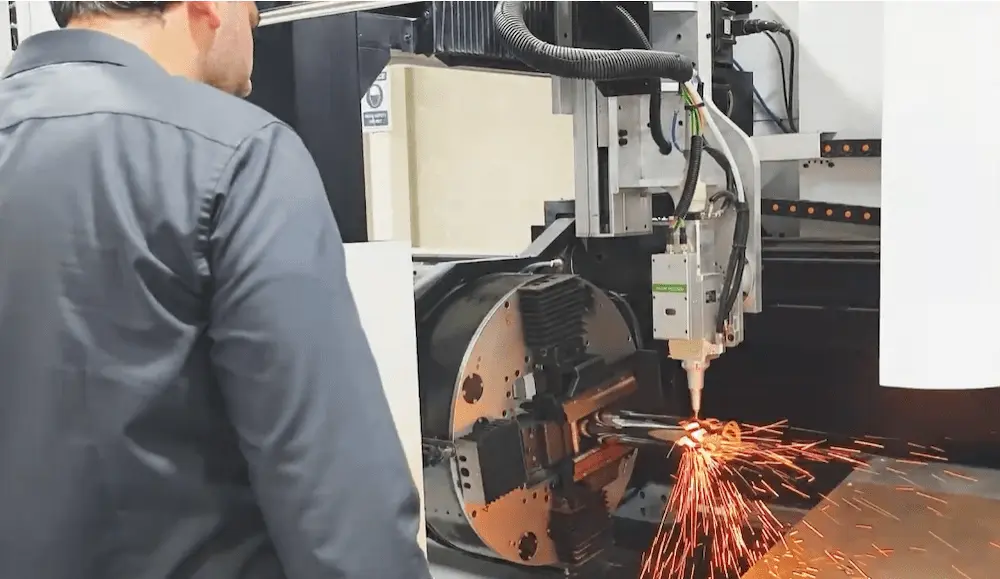

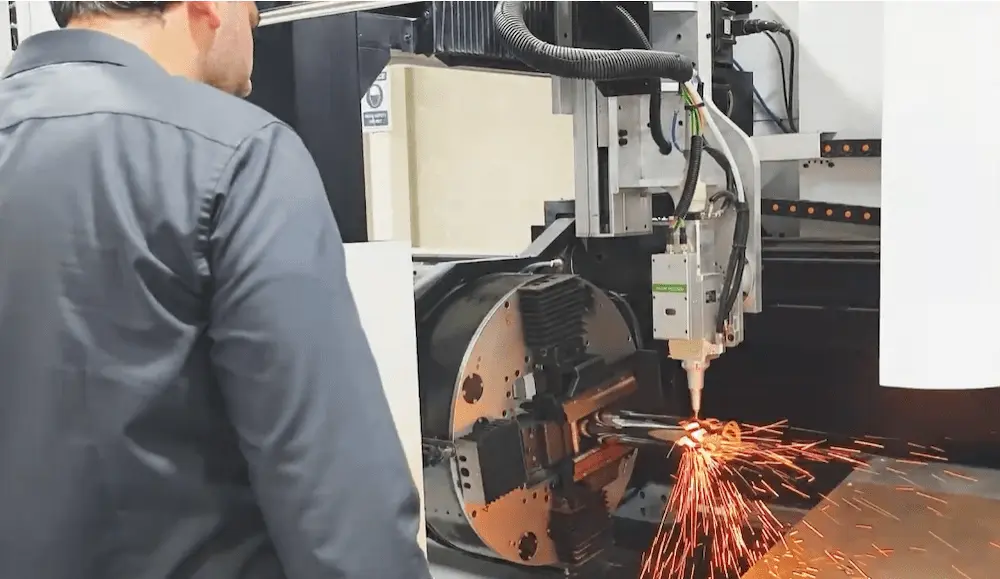

Metal laser cutting machines use fiber laser technology, which is specifically developed for cutting metallic materials. Unlike traditional CO₂ laser systems designed primarily for non-metal materials, fiber lasers deliver the high power density required for efficient metal processing.

The laser beam is generated by the laser source and transmitted through an optical fiber to the cutting head. Inside the cutting head, the beam is collimated and precisely focused onto the metal surface. The high-energy beam melts the material, while assist gas blows the molten metal out of the cutting kerf, producing a clean and precise cut.

Materials suitable for metal laser cutting

Industrial metal laser cutting machines are suitable for processing a wide range of metals and alloys, including:

-

Carbon steel and structural steel

-

Stainless steel

-

Galvanized steel

-

Aluminum and aluminum alloys

-

Copper, brass, and other reflective metals

-

Titanium

-

Electrical steel and special alloys

Applications of metal laser cutting machines

Metal laser cutting technology is widely used across many industrial sectors, including:

- Sheet metal fabrication

- Mechanical engineering and equipment manufacturing

- Automotive and transportation industries

- Construction and architectural metalwork

- Electrical and control cabinet production

- Medical and commercial equipment manufacturing

Laser cutting is commonly used to produce:

- Machine housings, panels, and enclosures

- Metal cabinets, racks, shelves, and furniture

- Doors, facades, and architectural cladding elements

- Electrical control boxes and ventilation components

- Structural parts and custom metal assemblies

- Decorative and perforated metal sheets

In addition to flat sheets, laser cutting technology can also be applied to pipes, profiles, and structural beams when equipped with suitable cutting modules.

Key criteria for choosing a metal laser cutting machine

A metal laser cutting machine is a complex industrial system. Its performance, cutting capability, and service life depend on the proper design and matching of all core components.

Laser Power

Laser power directly determines the maximum cutting thickness and processing speed. Higher power enables faster cutting and greater material capacity, especially for thick plates. For industrial applications, selecting sufficient laser power is critical to long-term productivity.

Machine Bed and Frame

A rigid, stress-relieved machine bed ensures stability, vibration resistance, and long-term precision. Proper heat treatment of the frame is essential to maintain geometric accuracy throughout the machine’s service life.

Motion System and Mechanical Components

The gantry, drive system, guide rails, and transmission components directly affect cutting speed, acceleration, and positioning accuracy. A well-engineered motion system ensures smooth operation, high repeatability, and consistent cutting quality.

Cutting Head and Control System

The cutting head must match the laser power and application requirements, while the CNC system should provide reliable control, intelligent functions, and user-friendly operation for industrial environments.