Introduction: Revolutionizing Precision Cutting

The Challenge of Traditional Laser Cutting

In industries like aerospace, semiconductors, and medical devices, traditional laser cutting often leaves behind heat damage, burrs, and uneven edges, leading to compromised material quality and costly post-processing. These challenges have driven the need for innovative solutions that deliver precision without sacrificing material integrity.

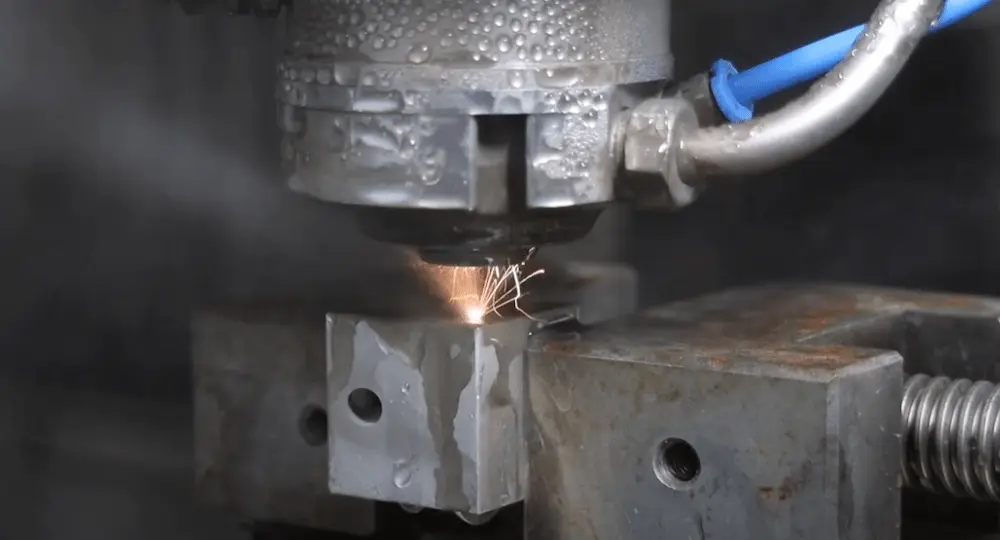

Enter the Water Jet Laser Cutting Machine

The water jet laser cutting machine, also known as Laser MicroJet, WJGL Cutting Machine, or water guided laser, is a game-changer. This hybrid technology combines a laser beam with a high-pressure water jet to achieve clean, accurate cuts with minimal thermal impact. It’s rapidly becoming the go-to solution for high-stakes manufacturing where precision is non-negotiable.

How It Works: A Quick Overview

A water jet laser cutting machine uses a pulsed laser (often Nd:YAG at 532 nm or 1064 nm) focused into a thin, high-pressure water jet (20–150 μm diameter, 50–600 bar). The water acts as a waveguide, directing the laser to the workpiece via total internal reflection, while cooling the cut zone and removing debris. This results in burr-free, parallel cuts with high aspect ratios (up to 400:1).

A Brief History of Innovation

The concept of guiding light through water dates back to the 1840s with Colladon’s experiments. By the 1990s, Synova SA commercialized this technology as Laser MicroJet, with recent advancements like 2024 integrations with HGTECH for automation and new service centers in Botswana expanding its global reach.

Why It Matters for Modern Manufacturing

Water guided laser systems offer unmatched precision for micro-machining, versatility across materials like silicon carbide, ceramics, and composites, and eco-friendly operation with reduced waste. From semiconductor wafer dicing to aerospace components, they eliminate heat-affected zones (HAZ), preserving material properties. This guide will explore the technology, benefits, applications, and tips for adopting WJGL cutting machines in your workflow.

Understanding the Technology: How Water Guided Laser Works

The Core Principle: A Hybrid Approach

Water guided laser technology, or Laser MicroJet (LMJ), blends the precision of laser cutting with the cooling and cleaning power of a water jet. Unlike traditional laser systems, it uses a high-pressure micro water jet (50–600 bar) as a “fiber optic” to guide a pulsed laser beam to the material surface. This hybrid method ensures precise energy delivery while mitigating thermal damage, making it ideal for delicate and high-value materials.

Step-by-Step Process

Here’s how a WJGL cutting machine operates:

-

Laser Coupling: A pulsed laser (commonly Nd:YAG at 532 nm for high water transmittance) is focused through a lens into a pressurized water jet exiting a tiny nozzle (20–150 μm diameter).

-

Waveguide Effect: The water jet acts like an optical fiber, guiding the laser via total internal reflection at the water-air interface, maintaining beam intensity over a long working distance (up to 50 mm).

-

Material Interaction: The laser ablates the material, while the water jet cools the cutting zone between pulses, preventing heat buildup, and flushes away debris, ensuring clean, burr-free edges.

-

Precision Cutting: The cylindrical water jet delivers a parallel laser beam, enabling high aspect ratio cuts (up to 400:1) without the conical kerfs common in traditional laser cutting.

Key Components of the System

-

Laser Source: Typically Nd:YAG lasers (532 nm or 1064 nm), with emerging use of UV lasers (355 nm) for specific applications. Short-pulse lasers (nanosecond or microsecond) enhance efficiency and finish quality.

-

Water Jet System: Uses filtered, deionized water to maintain jet stability and minimize laser absorption. Nozzle design and pressure control (50–600 bar) are critical for performance.

-

Coupling Unit: Aligns the laser into the water jet with high precision, ensuring minimal energy loss and stable beam delivery.

-

Protective Gas: Stabilizes the water jet’s coherence length, enhancing cutting consistency.

Why It’s Unique

The water jet’s dual role as a waveguide and coolant sets WJGL apart. It eliminates the need for focal adjustments, allows cutting of complex 3D geometries, and reduces thermal effects, making it suitable for materials like silicon, titanium, and carbon fiber-reinforced polymers (CFRP). For example, studies on CFRP cutting show that water jet pressures of 400 bar and laser powers of 240 W achieve optimal cutting speeds (21 mm/min) with minimal edge damage.

Visualizing the Process

For a clearer understanding, imagine a laser beam traveling through a flexible, liquid “fiber” that cools and cleans as it cuts. Diagrams or videos (like those on Synova’s website) can illustrate this synergy, showing how the water jet maintains laser focus while preventing heat-affected zones (HAZ). This makes WJGL a cornerstone for precision manufacturing.

Advantages of WJGL Cutting Machines Over Traditional Methods

Superior Precision and Cut Quality

Water jet guided laser cutting delivers exceptional precision, producing parallel, burr-free edges with high aspect ratios (up to 400:1 for cuts, 20:1 for bores). Unlike conventional laser cutting, which often results in conical kerfs due to beam divergence, the cylindrical water jet ensures consistent cut width, ideal for micro-machining applications like semiconductor wafer dicing or jewelry processing.

Minimal Thermal Damage

The water jet cools the cutting zone between laser pulses, eliminating heat-affected zones (HAZ) that can degrade material properties in traditional laser cutting. This is critical for heat-sensitive materials like silicon, titanium alloys, or CFRP, where thermal stress can cause microcracks or warping. For example, in CFRP cutting, WJGL at 240 W and 400 bar achieves a minimal matrix-fiber erosion zone (MFEZ) of ~1 mm, preserving structural integrity.

Enhanced Surface Quality

By flushing away molten debris and preventing oxidation, the water jet ensures smooth, clean surfaces with minimal post-processing. This burr-free laser cutting with water reduces the need for secondary finishing, saving time and costs in industries like medical device manufacturing, where surface purity is paramount.

Versatility Across Materials

WJGL cutting machines excel at processing a wide range of materials, from ultra-hard ceramics and diamonds to soft polymers and composites. Applications include cutting silicon carbide (SiC) for semiconductors, titanium for aerospace, and biocompatible polymers for medical implants, all without compromising material integrity.

Eco-Friendly and Efficient

The water guided laser process minimizes waste by reducing debris and eliminating the need for abrasive additives used in traditional waterjet cutting. It also lowers energy consumption compared to high-power conventional lasers, as the water jet enhances cutting efficiency. This makes WJGL a sustainable choice for modern manufacturing.

Comparison to Traditional Methods

-

Traditional Laser Cutting: Produces HAZ, conical cuts, and potential burrs; requires frequent focal adjustments and more post-processing.

-

Abrasive Waterjet: Effective for thick materials but introduces abrasive wear and less precision for micro-cuts.

-

WJGL Advantage: Combines laser precision with water jet cooling, offering parallel cuts, no thermal damage, and reduced waste, as validated by studies showing optimal CFRP cutting at 21 mm/min with minimal edge chipping.

Applications of Laser MicroJet Technology

Semiconductor and Electronics Manufacturing

In the electronics industry, water guided laser excels at micro-machining tasks like wafer dicing, etching plasma confinement rings, and cutting synthetic diamonds. Its ability to process brittle materials like silicon (Si) and silicon carbide (SiC) without thermal damage or mechanical stress makes it ideal for AI chip production, where 2023 global demand reached 16.4 million units, often requiring 2–4 ultra-hard ceramic heat sinks per chip.

Medical Device Manufacturing

WJGL’s non-contact cutting minimizes contamination risks, making it perfect for medical devices like surgical tools and implants. The water jet’s cooling ensures biocompatible materials (e.g., polymers, titanium) retain their properties, enabling precise cutting and drilling for complex shapes with high surface quality, critical for long-term performance in the body.

Aerospace Engineering

Aerospace demands high precision for difficult-to-machine materials like ceramic matrix composites (CMC) and carbon fiber-reinforced polymers (CFRP). WJGL tackles tasks like turbine blade cooling hole drilling and CFRP structural component cutting, achieving clean edges without delamination. For instance, research shows WJGL cuts 6 mm CFRP at 21 mm/min with minimal thermal damage at 240 W and 400 bar.

Jewelry and Watchmaking

In gemstone processing, water jet laser cutting reduces material loss and health risks from dust. It cuts diamonds and other hard materials with near-zero taper, minimizing cracks and maximizing yield. The water jet’s cooling prevents thermal stress, ensuring flawless surfaces for high-value products.

Emerging Applications

WJGL is expanding into electric vehicle (EV) prototyping, cutting electrical steel laminations, and microelectronics, where integration with CAD/CAM systems enables automated, precise machining. Its versatility makes it a go-to for industries requiring high precision and minimal waste.

Water Jet Guided Laser vs. Conventional Laser Cutting: A Detailed Comparison

Side-by-Side Comparison

|

Aspect |

Water Jet Guided Laser (WJGL) |

Conventional Laser Cutting |

|---|---|---|

|

Thermal Damage |

Minimal (water cooling eliminates HAZ) |

High HAZ, potential microcracks |

|

Cut Quality |

Burr-free, parallel edges |

Conical kerfs, possible burrs |

|

Material Versatility |

Wide (metals, ceramics, composites) |

Limited by heat sensitivity |

|

Precision |

High aspect ratios (400:1) |

Moderate, focus-dependent |

|

Post-Processing |

Minimal (clean surfaces) |

Often required (burrs, HAZ) |

|

Eco-Friendliness |

Low waste, no abrasives |

Higher waste, energy-intensive |

Key Differentiators

WJGL’s water jet eliminates focal adjustments, enabling 3D cutting and long working distances (up to 50 mm). Studies on CFRP show that increasing water jet pressure from 100 to 500 bar boosts cutting speed and material removal efficiency, though higher pressures may increase edge chipping. Conventional lasers, while cost-effective for simpler tasks, struggle with heat-sensitive materials and complex geometries.

Choosing the Right Water Jet Laser Cutting Machine: Buyer’s Guide

Key Factors to Consider

-

Laser Type: 532 nm Nd:YAG for high water transmittance; 1064 nm for cost-effectiveness; 355 nm UV for niche applications.

-

Water Jet Pressure: 50–600 bar, with 400 bar optimal for balancing speed and quality in materials like CFRP.

-

Nozzle Size: 20–150 μm for varying cut widths and precision needs.

-

Automation: Integration with CAD/CAM for smart manufacturing, as seen in Synova’s 2024 HGTECH collaborations.

Leading Manufacturers

Synova SA, the pioneer of Laser MicroJet, leads the market with systems like the LCS series, tailored for aerospace and semiconductors. Other players include HGTECH, offering integrated solutions for industrial applications.

Cost and Maintenance Tips

While initial costs are higher than conventional lasers, WJGL reduces long-term expenses by minimizing post-processing. Use deionized water to prevent nozzle clogging and maintain jet stability. Regular calibration of the coupling unit ensures consistent laser delivery.

FAQs

-

Can WJGL cut thick materials? Yes, but it excels in thin to medium thicknesses (e.g., 6 mm CFRP) with high precision.

-

Is it suitable for my industry? If you work with heat-sensitive or hard materials, WJGL is likely a fit.

Future Trends and Innovations in Water Jet Guided Laser Cutting

Advancements in Laser and Jet Technology

Research is improving laser sources (e.g., UV lasers for higher precision) and jet stability through advanced nozzles and pressure control. Numerical models are optimizing laser-water-material interactions for complex tasks like blind hole drilling.

Integration with Smart Manufacturing

WJGL’s compatibility with CAD/CAM and automation systems is driving its adoption in Industry 4.0. Synova’s 2024 partnerships with HGTECH highlight this trend, enabling real-time process optimization.

Sustainability Focus

By reducing waste and eliminating abrasives, WJGL aligns with green manufacturing goals. Its low energy consumption compared to traditional lasers makes it a sustainable choice.

Expanding Applications

Expect wider use in electric vehicle battery production, microelectronics, and advanced composites as industries demand precision and efficiency. Research into cutting thicker materials with higher-power lasers is also underway.

Conclusion: Why Invest in a WJGL Cutting Machine Today

Water jet laser cutting machines, or Laser MicroJet systems, are redefining precision manufacturing with their ability to deliver clean, heat-free cuts across diverse materials. From semiconductors to aerospace, their minimal thermal impact, high precision, and eco-friendly operation make them indispensable. Whether you’re optimizing production or tackling complex geometries, WJGL offers a competitive edge. Subscribe for more insights on precision machining or contact a supplier to explore how water guided laser technology can transform your workflow.