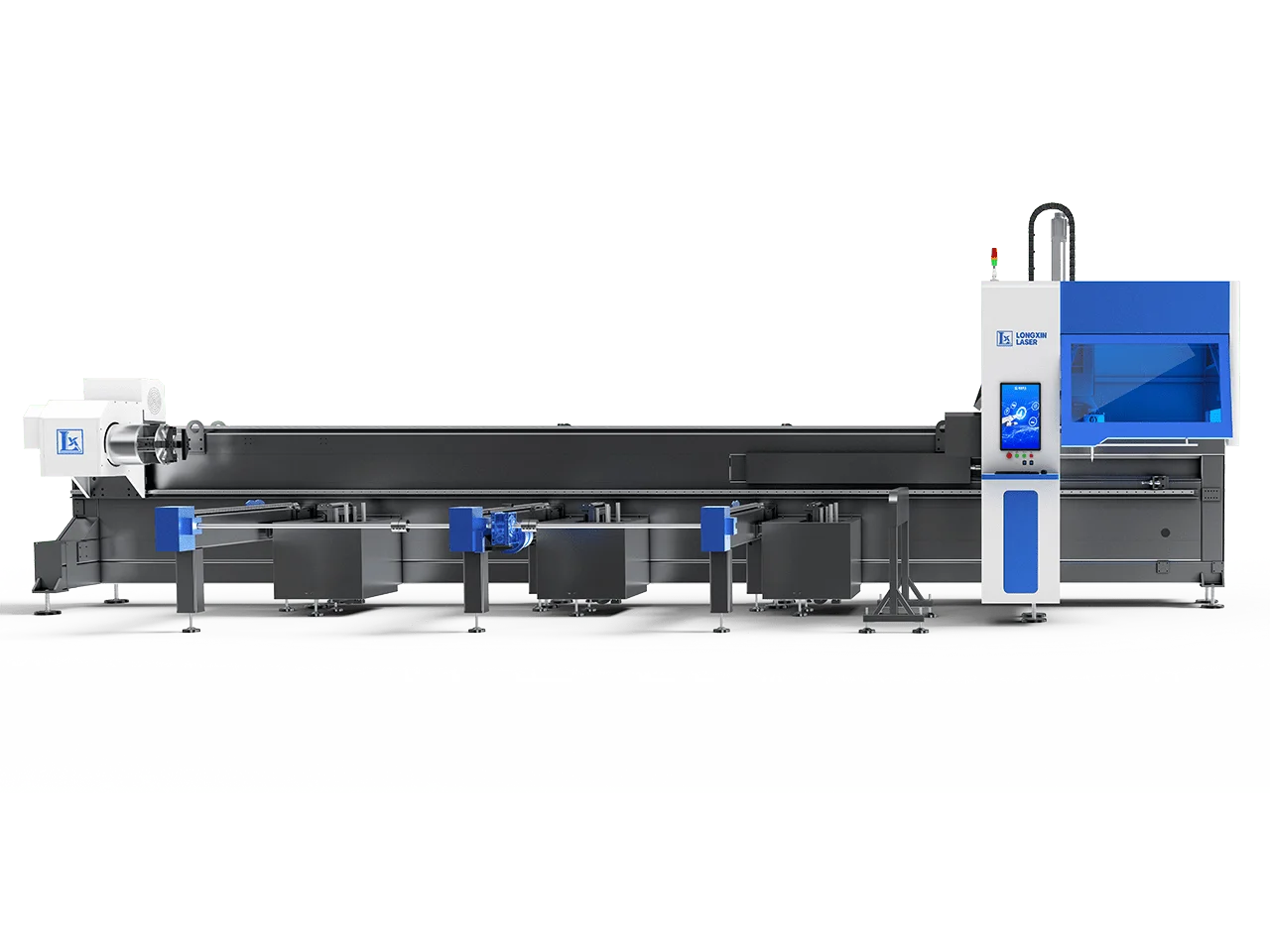

3D-Laser-Rohrschneidemaschine

LX-K28

- Seitlich montiertes Spannfutter, ultrakurzes Heck

- Große Verarbeitungsgröße, hohe Kostenleistung

- Hohe Produktionseffizienz, stabiler Betrieb

- Verarbeitungsbereich: Rundrohr: ∅20-280mm Vierkantrohr: □20*20-280*280mm

Produktmerkmale

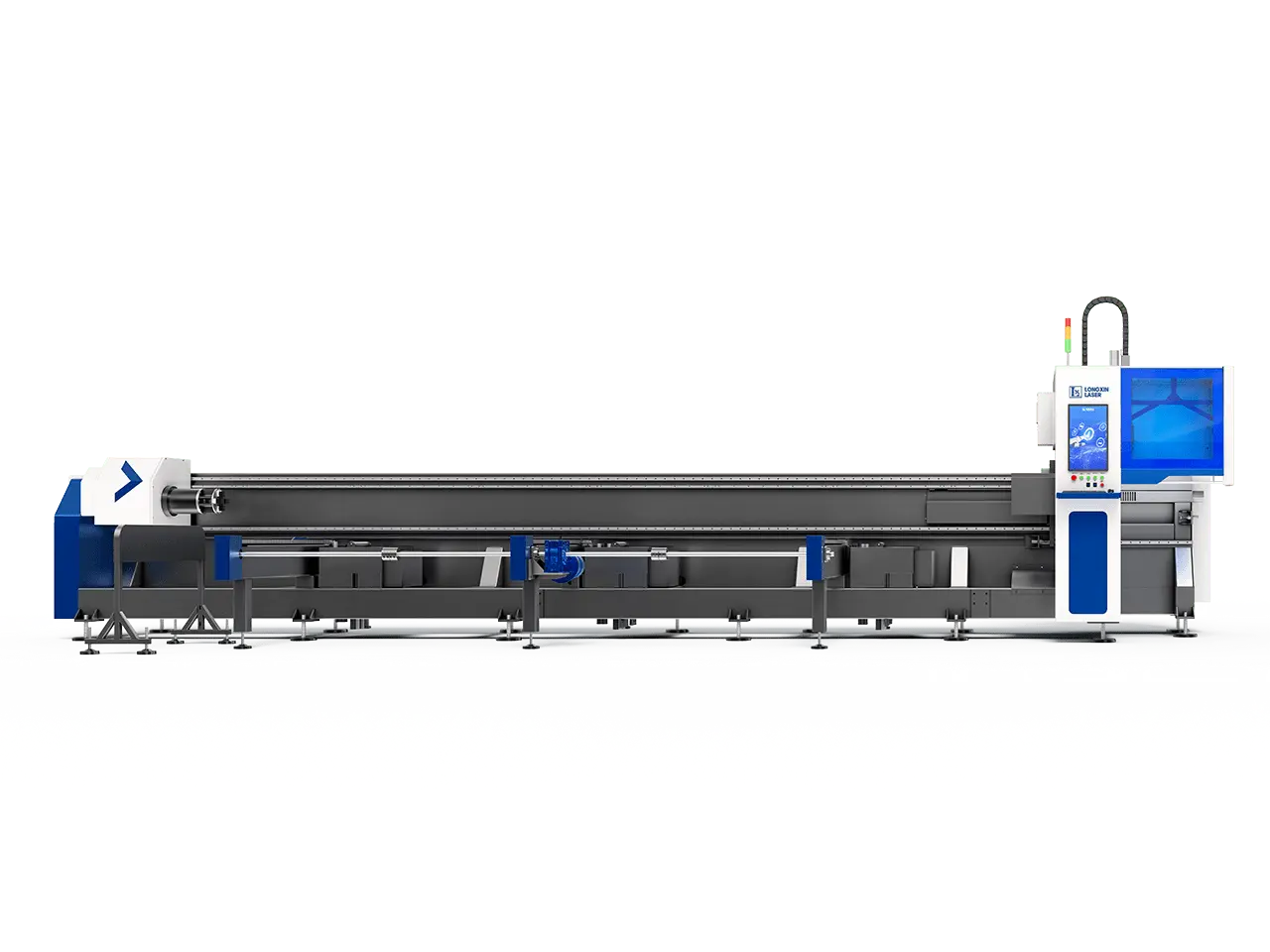

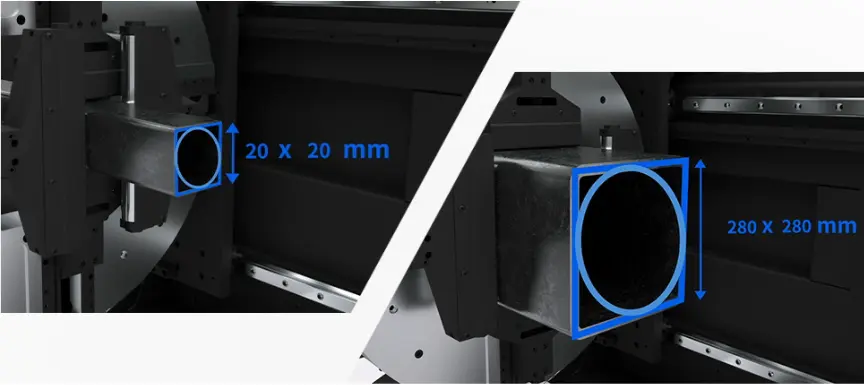

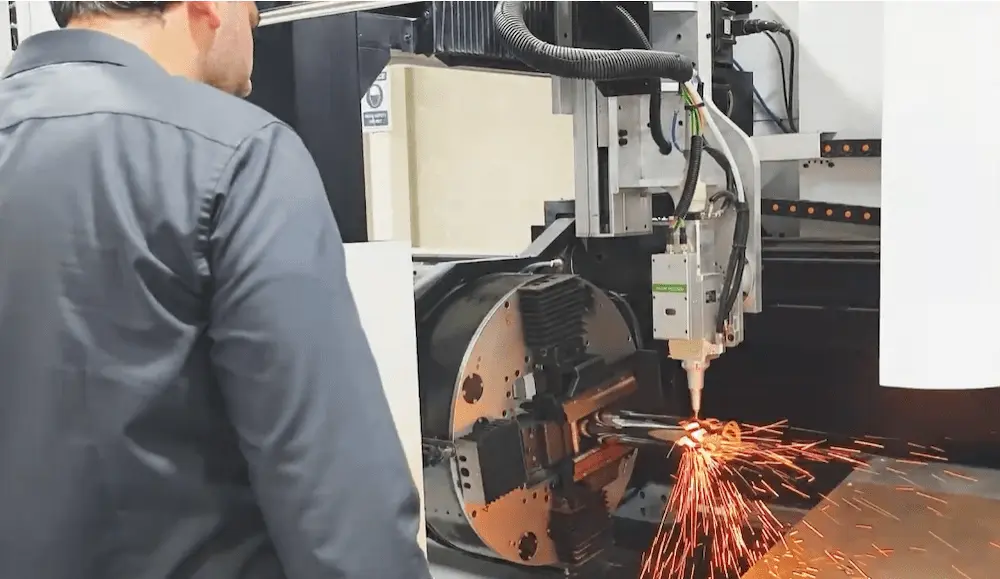

Beste Wahl für die Verarbeitung großer Rohre

Die Konstruktion der Seitenlader-Drehmaschine ermöglicht eine einfache Zuführung von Rohrmaterialien mit großem Durchmesser. Sie kann runde Rohre mit Durchmessern von 20-280 mm sowie Vierkantrohre mit Abmessungen von 20x20 mm bis 280x280 mm bearbeiten.

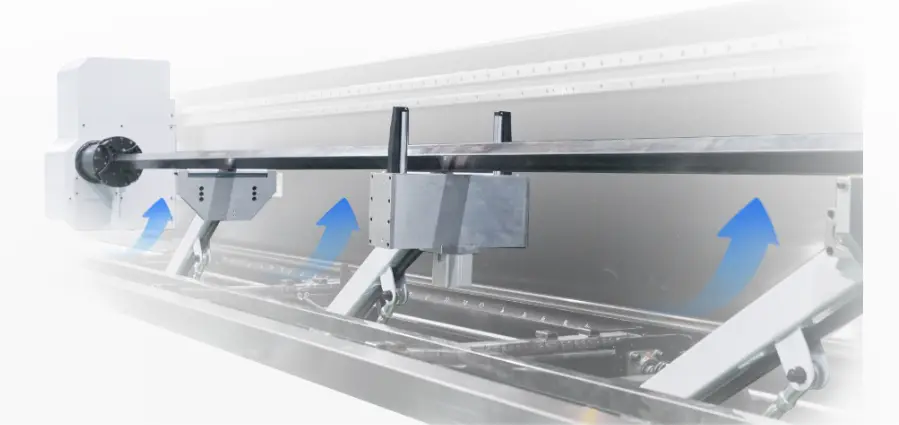

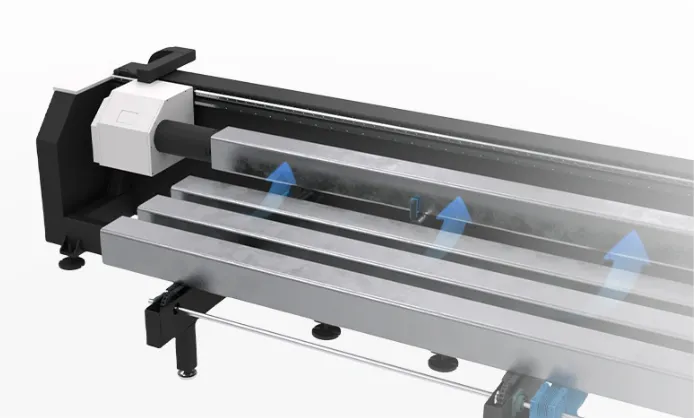

Servo Follow-Up Material Support System

Eine Servo-Nachlaufeinrichtung sorgt für das Anheben und Abstützen der Rohre während der Bearbeitung in Echtzeit, wodurch die Stabilität und Präzision des Schnitts erheblich verbessert wird.

Vollständig automatisiertes Laden über die Array-Konfiguration

Er kann automatisch 4 große Rohre auf einmal laden, was den Betrieb vollautomatisch, einfach und sorgenfrei macht.

Intelligentes CNC-System, speziell für das Schneiden von Rohren entwickelt

Das System verfügt über einen visuellen Betriebsbildschirm, einfache Parametereinstellungen und eine breite Palette von Funktionen. Es unterstützt unter anderem mehrstufige Perforation, intelligenten Werkzeugrückzug, automatische Kantenerkennung und intelligente Verschachtelung.

Technische Parameter

- Modell:

- Laser power:

- Durchmesser Von Rundrohr:

- Schneiden Durchmesser Vierkantrohr:

- Schneiden Rohr Länge:

- Genauigkeit Von Bearbeitung:

- Abmessungen:

- Gewicht:

- Schneiden Rohr Typ:

- Schneiden Material:

Video

Benötigen Sie weitere Informationen? Kontaktieren Sie uns noch heute und wir vereinbaren ein vertrauliches Gespräch, um Ihr Projekt zu besprechen.

Zuverlässige Qualität mit internationalen Zertifizierungen

Unsere Zertifikate, die die Qualität, Zuverlässigkeit und Übereinstimmung unserer Produkte mit internationalen Normen belegen.

Schneiden von Mustern

Referenzen

Koreas führender Stahlkonstruktionshersteller modernisiert seine Produktion mit der Dreifach-Spannfutter-Schrägschnitt-Rohrschneidemaschine LX-T35 von Longxin Laser.

Wie die 3D-Laser-Rohrschneidemaschine LX-K24 von Longxin die Produktivität von Jinjia Building Materials um 20% gesteigert hat

Kunde aus der Baubranche in Dubai steigert Produktivität mit der Dreifach-Spannfutter-Laserrohrschneidemaschine LX-K28 von Longxin

Longxin Laser Machine LX-K6 in Südafrika

Produktionslinie für Laserschneidmaschinen für Bettgestelle Fallstudie

Kundenfall: Dubai - Hochleistungs-Rohrlaserschneiden für die Zaunindustrie

Automatisiertes Hochgeschwindigkeits-Rohrschneiden und Anfasen in der Türkiye

Longxin Laser-Rohrschneidmaschine K9max unterstützt Indonesiens Metallrohrindustrie bei der Automatisierung

Vorwärts rasen: Umgestaltung der Konsolenfertigung - Longxin Laser

Warum Longxin-Laser?

Hochmoderne Technologie

Wir verwenden die fortschrittlichste Laserrohrschneidetechnik, um Präzision und hohe Qualität bei jedem Produkt zu gewährleisten.

Umfassende Erfahrung

Mit mehr als 15 Jahren Erfahrung im Rohrschneiden verstehen wir, was Sie brauchen.

Effiziente Produktion

Unsere Produktionslinie läuft effizient und produziert mehr als 300 Maschinen pro Monat.

Kundenspezifische Automatisierung

Wir bieten einen spezialisierten, maßgeschneiderten Service für Ihre Bedürfnisse.

Kundendienst

Unser engagiertes Kundendienstteam ist immer bereit, Ihnen zu helfen

Intelligente Software

Hochintegrierte intelligente Rohrschneidlösungen

Verwandte Produkte

Angebot anfordern

Bitte füllen Sie das folgende Formular um uns zu Kontaktieren und bieten uns Ihre Anforderungen. Wir wird zurück zu Ihnen innerhalb von 24 Stunden.

Angebot anfordern

Bitte füllen Sie das folgende Formular um uns zu Kontaktieren und bieten uns Ihre Anforderungen. Wir wird zurück zu Ihnen innerhalb von 24 Stunden.