Find Your Perfect Laser Cutting Machine Match Without Overpaying

Laser cutting machines vary enormously in price depending on laser type, power, and features. Hobbyist diode or desktop CO₂ cutters can cost only a few hundred to a few thousand USD, while industrial metal-cutting systems (especially high-power fiber lasers) run into the tens or even hundreds of thousands.

For example, small diode- or CO₂-based desktop cutters start around $300–$2,000, whereas fiber laser cutters for heavy sheet-metal work typically start in the $20,000+ range.

In general, fiber lasers carry the highest price per watt, CO₂ lasers are mid-range, and diode lasers are the cheapest type.

Figure: Global laser-cutting machine market is growing rapidly (projected $132.3 B by 2033scoop.market.us), reflecting broad industrial demand. Price remains a key consideration for buyers in this expanding market.

Laser Types & Price Ranges (USD)

| Type | Power Range | Core Applications | Price Range | Best For |

|---|---|---|---|---|

| Fiber | 500W – 12kW+ | Metals (steel, aluminum, copper) | $20,000 – $500,000 | Automotive, aerospace |

| CO₂ | 40W – 6kW | Wood, acrylic, fabrics, thin metals | $500 – $100,000 | Signage, crafts, education |

| Diode | 5W – 100W | Paper, leather, thin plastics | $300 – $4,000 | Hobbyists, prototypes |

*(Source: Aggregated from 120+ B2B platforms including Alibaba, Thomasnet, and industry reports)*

Critical Cost Drivers

(1) Laser Power

- Fiber lasers: +$8,000 – $12,000 per kW

- CO₂ lasers: +$1,500 per 100W (above 1kW)

(2) Automation & Integration

- Basic manual loading: $0 add-on

- Features like auto loading/unloading, nesting software, remote monitoring, and in-tower part management add significantly to cost—typically $20k–$100k+, depending on system complexity.

(3) Work Area Size

- Standard 1.5×3m machines cost around $20,000–$50,000.

- Upgrading to 3×6m adds 40–70% to the price, reaching $35,000–$85,000.

(4) Cutting Type: Plate vs. Tube

- Tube-cutting machines are generally more expensive than plate-cutters due to the need for rotary axes, specialized chucks, and multi-axis control.

- These extras increase mechanical complexity and precision requirements—adding typically 20–50% to the base price compared to equivalent plate cutters.

(5) Laser Source Brand & Quality

- Premium fiber sources (e.g., IPG, nLIGHT) offer better efficiency, lifespan, and stability—but cost more than common budget options like Raycus or Max Photonics

(6) Brand Reputation & Support

- stablished brands with extended warranties, global support, and reliable spare parts come at a premium—but pay off over time

Regional Price Benchmarks

| Region | Fiber 3kW (Avg.) | CO₂ 200W (Avg.) | Key Influences |

|---|---|---|---|

| North America | $68,000 – $90,000 | $12,000 – $18,000 | Strict certifications |

| Western Europe | €62,000 – €84,000 | €10,500 – €16,000 | Energy efficiency reqs |

| Southeast Asia | $42,000 – $58,000 | $8,000 – $12,000 | Shipping/tariff costs |

Hidden Costs Checklist

⚠️ Evaluate these before purchasing:

-

Energy Consumption: Fiber lasers cost $0.8/hr (3kW), CO₂ cost $2.5+/hr

-

Maintenance: Annual upkeep = 3-8% of machine price

-

Cutting Gas: Oxygen/Nitrogen systems add $5,000-$20,000

-

Training: Operator courses $800-$2,500

Buyer’s Decision Map

Procurement Tips

- Test Before Buy: 92% suppliers offer free sample cutting

- Warranty Matters: Opt for 24+ month coverage on laser source

- Shipping Savvy: Sea freight: $3k-$8k (40ft container) Air freight: 3x sea cost (emergency only)

- Proven ROI Formula: Break-Even Months = Machine Price ÷ [(Monthly Output Value) – (Labor+Energy+Gas)]

Common types of lasers used in laser cutting machines

(1). CO₂ Laser Cutting Machines

Applications: General-purpose cutting for signage, advertising, packaging, woodworking, and prototyping. Cuts wood, acrylic, glass, leather, paper, rubber, textiles, and plastics. Can handle non-ferrous metals and coated steel with oxygen assist.

Power Range: 40-150W for desktop units, 0.5-6kW for industrial systems. Hobbyist models: 40-150W. Large industrial systems: 2-3kW for metal sheets up to 12mm thick.

Materials: Wood, plywood, MDF, acrylic, fabrics, leather, paper, cardboard, rubber, glass. Limited metal cutting capability with thin aluminum and mild steel using oxygen assist.

Price Range:

- Desktop/entry units: $1,000-$5,000

- Mid-range shop cutters: $10,000-$25,000

- Heavy-duty industrial: $50,000-$100,000+

Key Features: Lower upfront cost per watt, 5-10% power efficiency. Requires gas tube replacement and regular mirror alignment. Cuts steel up to 100mm with oxygen assist.

(2). Diode Laser Cutting Machines

Applications: Hobbyist and light-industrial engraving. Wood, leather, rubber, and thin plastic cutting. Portable laser marking, PCB marking, shallow metal engraving, and craft applications.

Power Range: 5-40W for desktop units. Industrial systems up to 100W (rare above 50W). Most common range: 30-40W for wood and acrylic cutting.

Materials: Thin organics only: wood veneer, cardboard, leather, fabric, paper, thin plastics. Cannot effectively cut metal, glass, or thick acrylic. Limited to materials under 5mm thickness.

Price Range:

- Simple engravers: $300-$1,000 (2-5W)

- Mid-range benchtop: $1,500-$4,000 (20-40W)

- Largest systems: $5,000-$10,000

Key Features: Lowest cost and maintenance. No gas requirements, compact design, simple fan cooling. Requires multiple passes for cutting, sensitive to material color and focus. Unsuitable for thick materials or serious metal work.

(3). Fiber Laser Cutting Machines

Applications: Metal cutting for automotive, shipbuilding, machinery manufacturing, and aerospace industries. Cuts steel, stainless steel, aluminum, copper, brass, and titanium up to several centimeters thick. Also used for metal engraving and precision component manufacturing.

Power Range: 0.5 kW to 12 kW for industrial models. Small shop units: 500-2000W. Large-format systems: 6-12 kW for thick plate cutting.

Materials: Optimized for metals, particularly reflective and high-strength alloys. Limited effectiveness on non-metals like plastics or wood.

Price Range:

- Entry-level: $20,000-$50,000

- Mid-range industrial: $80,000-$200,000

- High-end systems: $500,000+

Key Features: 90%+ electrical efficiency, 25,000+ hour laser lifetime, low operating costs. Higher upfront investment than CO₂ systems but superior performance on reflective metals.

Fiber Laser Cutting Machines Types:

Fiber laser cutting machines fall into two main categories: sheet laser cutters and tube laser cutters. Each serves distinct applications with different power requirements and pricing structures.

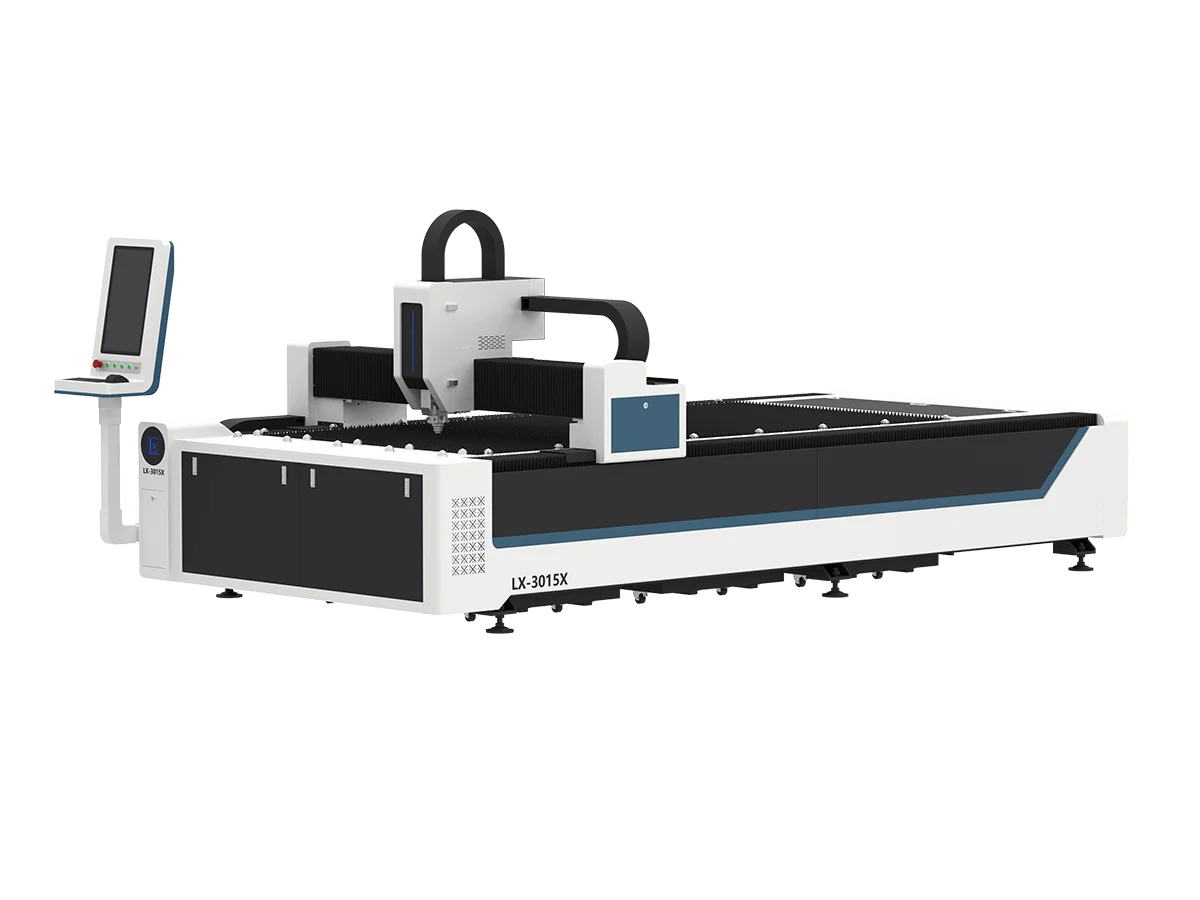

(1). Sheet Laser Cutting Machines

- Applications: Cut flat metal sheets including steel, stainless steel, and aluminum. Used in manufacturing, metal fabrication, automotive panels, and electronic enclosures

- Power Range: 1-6kW standard, up to 12kW for heavy plate cutting

- Price Range:

- Entry-level: $15,000-$50,000

- Mid-range: $50,000-$150,000

- Industrial: $150,000-$300,000+

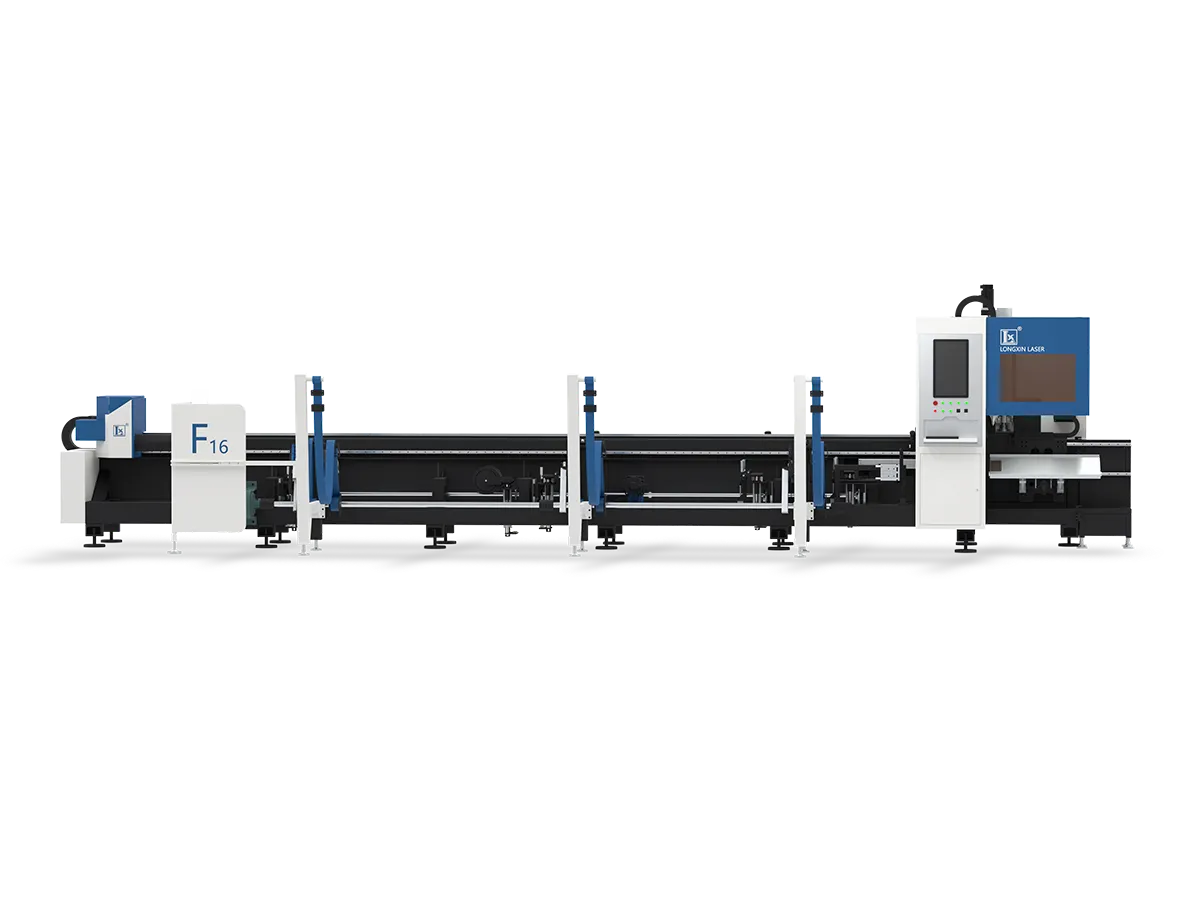

(2). Tube Laser Cutting Machines

- Applications: Cut round, square, and rectangular tubes plus various profiles. Common in furniture frames, exhaust systems, and structural components

- Power Range: 1-4kW mainstream, premium systems exceed 6kW

- Price Range:

- Entry-level: $30,000-$45,000

- Mainstream: $45,000-$100,000

- Premium: $100,000-$400,000+

Selection Guide

Sheet cutters work best for businesses processing flat metal plates. Power requirements typically range 1-6kW with investments from $15,000 to $300,000+. Tube cutters target pipe and profile work, using 1-4kW power with pricing starting at $30,000 and reaching $400,000+ for advanced automation.

Tube cutters cost more at entry level due to complex fixtures and rotation systems needed for cylindrical cutting. Price variations depend on cutting diameter capacity, axis complexity, and automation features.

Summary

Laser cutter costs span from a few hundred dollars up to hundreds of thousands, depending on type and power.

Diode lasers are cheapest (hundreds to low thousands USD) and suit hobby/entry-level cutting of thin non-metals.

CO₂ lasers cover a broad mid-range: small CO₂ cutters (~40–150 W) cost a few thousand USD, while industrial CO₂ systems (1–6 kW) cost tens of thousands.

Fiber lasers command the highest prices: even compact units start tens of thousands, and full-scale metal-cutting systems (several kW) can run $100k or more.

Buyers should match the machine type and power to their materials (fibers for thick metals, CO₂ for non-metals and some metals, diode for light-duty) and weigh features like worktable size and automation.