1. Introduction

Laser welding technology has revolutionized manufacturing processes across industries, offering unparalleled precision, speed, and versatility. However, the cost of laser welding equipment often becomes a critical factor in the decision-making process for businesses considering this investment.

In this comprehensive guide, we’ll explore:

- Detailed breakdowns of laser welder prices by type and capability

- In-depth analysis of factors influencing laser welding machine costs

- Real-world examples of total cost of ownership calculations

- Expert tips for optimizing your laser welding investment

Whether you’re a small workshop owner or a large manufacturing facility manager, this guide will help you navigate the complex landscape of laser welding machine expenses.

2. Types of Laser Welding Machines and Their Price Ranges

a) Handheld Laser Welder Price

- Range: $4,700 – $26,300

- Popular models:

- Entry-level (1000W): $5,000 – $8,000

- Mid-range (1500W): $10,000 – $15,000

- High-end (2000W+): $18,000 – $26,300

- Best for: Small workshops, on-site repairs, jewelry making

- Key benefits: Portability, ease of use, low initial investment

b) CNC Laser Welding Machine Pricing

- Range: $30,000 – $150,000+

- Price breakdown by power:

- 300W – 500W: $30,000 – $50,000

- 600W – 1000W: $50,000 – $80,000

- 1000W – 2000W: $80,000 – $150,000+

- Best for: Medium to large manufacturing enterprises, automotive parts production

- Key benefits: High precision, automation capabilities, consistent weld quality

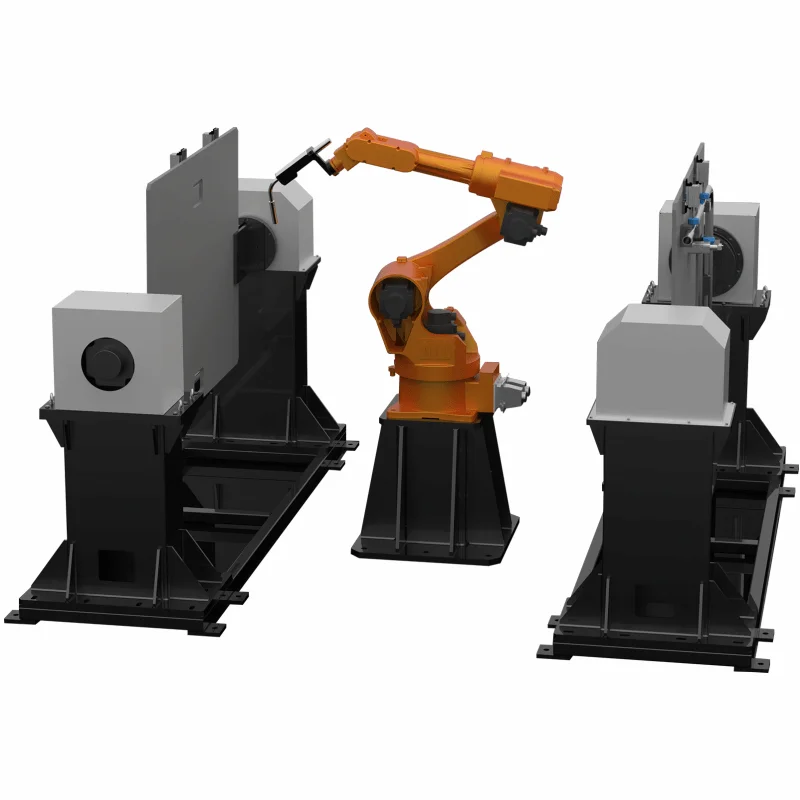

c) Industrial Laser Welding Robot Expenses

- Range: $100,000 – $500,000+

- Cost factors:

- Robot arm reach and payload capacity

- Laser source power (typically 2000W – 6000W)

- Integration complexity and custom programming

- Best for: Large-scale production, automotive assembly lines, aerospace industry

- Key benefits: Highest level of automation, 3D welding capability, integration with production lines

d) Combination Laser Cutter and Welder Pricing

- Range: $50,000 – $200,000

- Price variations:

- Basic models (500W – 1000W): $50,000 – $80,000

- Advanced models (1000W – 2000W): $80,000 – $150,000

- High-end systems (2000W+): $150,000 – $200,000+

- Best for: Job shops, prototyping facilities, versatile manufacturing operations

- Key benefits: Multi-functionality, space-saving, cost-effective for businesses needing both cutting and welding

3. Factors Influencing Laser Welding Machine Costs

a) Laser Power

- Impact on price: 15% – 30% increase per power doubling

- Example: A 1000W system might cost $50,000, while a 2000W system could be $65,000 – $75,000

- Considerations: Higher power allows for faster welding speeds and thicker materials

b) Precision and Beam Quality

- High-precision systems can cost 20% – 40% more than standard models

- Beam quality factors:

- Beam Parameter Product (BPP): Lower BPP = Higher quality = Higher cost

- M² value: Closer to 1 = Better quality = More expensive

c) Automation Features

- Basic CNC control: Included in base price

- Advanced features cost breakdown:

- Automatic tool changing: $5,000 – $15,000

- Vision systems for weld tracking: $10,000 – $30,000

- Integrated quality control systems: $20,000 – $50,000

d) Brand Reputation and After-Sales Support

- Premium brands may charge 10% – 25% more than lesser-known manufacturers

- Factors to consider:

- Warranty length and coverage

- Availability of local service technicians

- Cost and availability of spare parts

e) Additional Features

- Specialized welding heads: $5,000 – $20,000 depending on complexity

- Advanced cooling systems: $3,000 – $10,000

- Fume extraction systems: $2,000 – $8,000

- Software for weld pattern design: $2,000 – $15,000 per license

4. Understanding the Total Cost of Ownership for Laser Welding Machines

a) Ongoing Operational Expenses

- Energy consumption:

- Average cost per hour: $1.50 – $3.00 for a 1000W system

- Annual cost (2000 hours operation): $3,000 – $6,000

- Consumables:

- Shielding gas: $500 – $2,000 per year

- Replacement parts (nozzles, lenses): $1,000 – $5,000 per year

- Maintenance:

- Routine maintenance: 2% – 5% of machine cost per year

- Example: $50,000 machine = $1,000 – $2,500 annual maintenance cost

b) Training and Labor Costs

- Initial operator training: $2,000 – $5,000 per operator

- Advanced training for technicians: $5,000 – $10,000 per person

- Potential salary increase for skilled operators: 10% – 20%

c) Depreciation and Resale Value

- Typical depreciation rate: 15% – 20% per year for the first 5 years

- Example: $100,000 machine might be worth $40,000 – $50,000 after 5 years

- Factors affecting resale value:

- Brand reputation

- Maintenance history

- Technological advancements in newer models

5. Cost Comparison: Laser Welding vs. Traditional Welding Methods

a) Initial Investment

- Laser welding: $30,000 – $500,000+

- Traditional welding (e.g., TIG, MIG):

- Basic setup: $2,000 – $5,000

- Advanced systems: $10,000 – $50,000

b) Operational Costs (based on 2000 hours annual operation)

- Laser welding:

- Energy: $3,000 – $6,000

- Consumables: $1,500 – $7,000

- Maintenance: $1,000 – $25,000 (depending on machine cost)

- Traditional welding:

- Energy: $1,000 – $3,000

- Consumables (electrodes, wire): $5,000 – $15,000

- Maintenance: $500 – $2,500

c) Long-term ROI Factors

- Productivity increase with laser welding: 30% – 50% in many applications

- Material savings: Up to 20% reduction in material waste

- Quality improvement: Potential 50% reduction in rework and scrap

6. Tips for Budget-Friendly Laser Welder Purchases

a) Explore Used and Refurbished Options

- Potential savings: 30% – 50% off original price

- Key checks before purchase:

- Operating hours

- Maintenance records

- Remaining laser source life

b) Leasing and Financing Options

- Typical lease terms: 3-5 years

- Monthly payments: Often 2% – 3% of total machine cost

- Benefits:

- Lower initial cash outlay

- Potential tax advantages

- Easier upgrades to newer technology

c) Grants and Incentives

- Government programs: Can cover 10% – 30% of equipment cost

- Energy efficiency rebates: Potential $5,000 – $20,000 savings

- Research and development tax credits: Up to 20% of qualifying expenses

7. Future Trends in Laser Welding Machine Pricing

a) Technological Advancements

- Fiber laser improvements: Potential 5% – 10% cost reduction per year

- Increased power efficiency: May lower operational costs by 10% – 20%

b) Market Competition

- New entrants from emerging markets: Could drive prices down 10% – 15%

- Consolidation among established players: Might stabilize or slightly increase prices

c) Emerging Technologies

- AI-assisted welding: Potential $10,000 – $50,000 add-on cost

- Green laser technology: May increase initial costs by 20% – 30% but offer long-term energy savings

By considering these detailed factors and leveraging the tips provided, businesses can make well-informed decisions about investing in laser welding technology, balancing the costs with the potential benefits to find the most cost-effective solution for their specific needs.