Laser cutting technologies have revolutionized manufacturing and design, offering precision and flexibility for various applications. This article explores the differences between 2D and 3D laser cutting, guiding engineers, designers, and fabricators in choosing the right method for their projects.

Understanding 2D Laser Cutting

Definition and Process

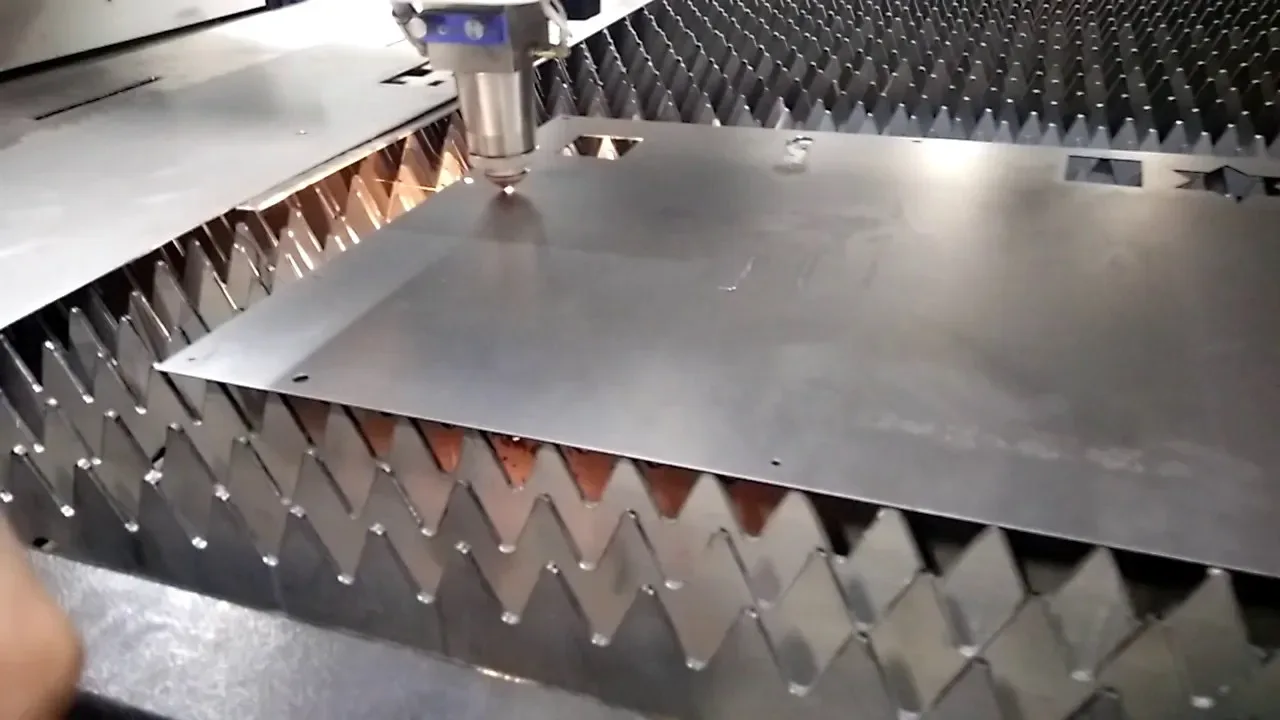

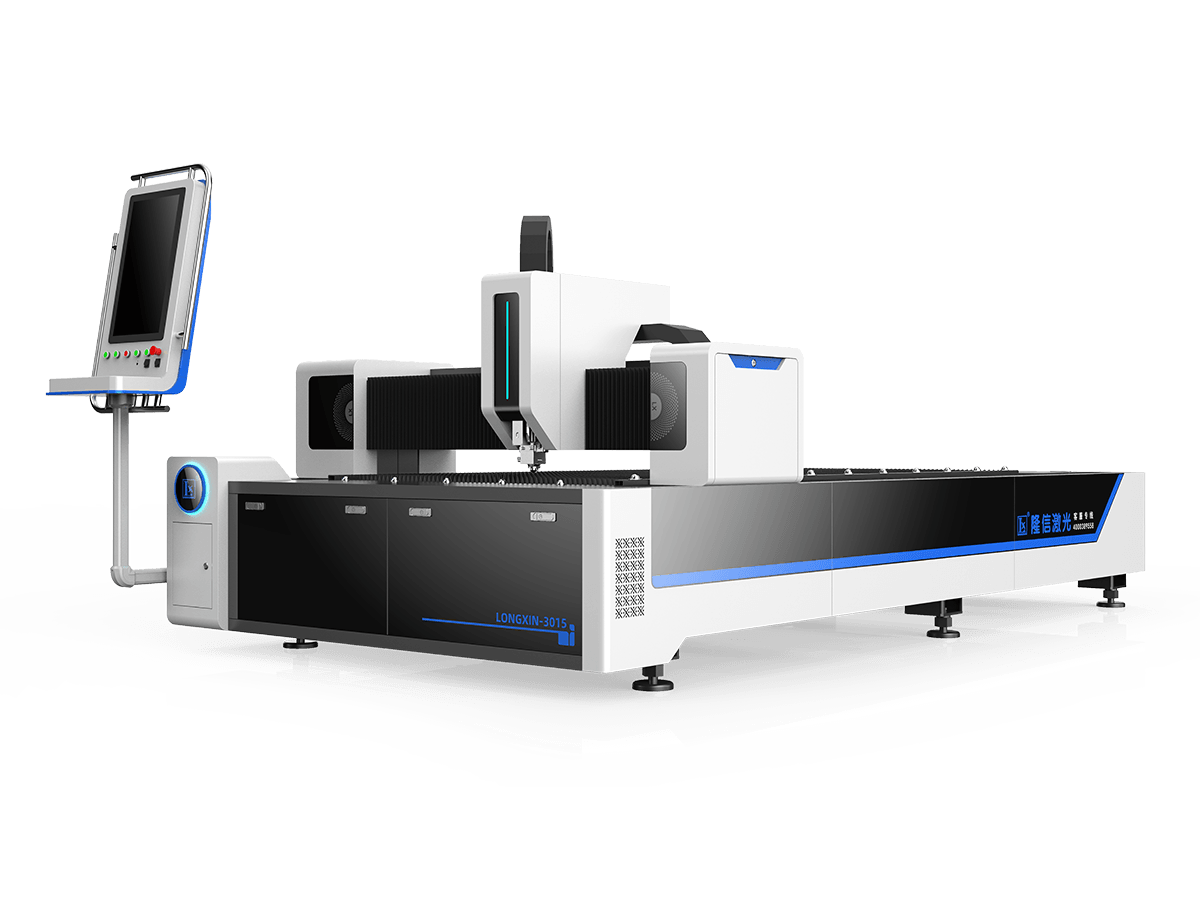

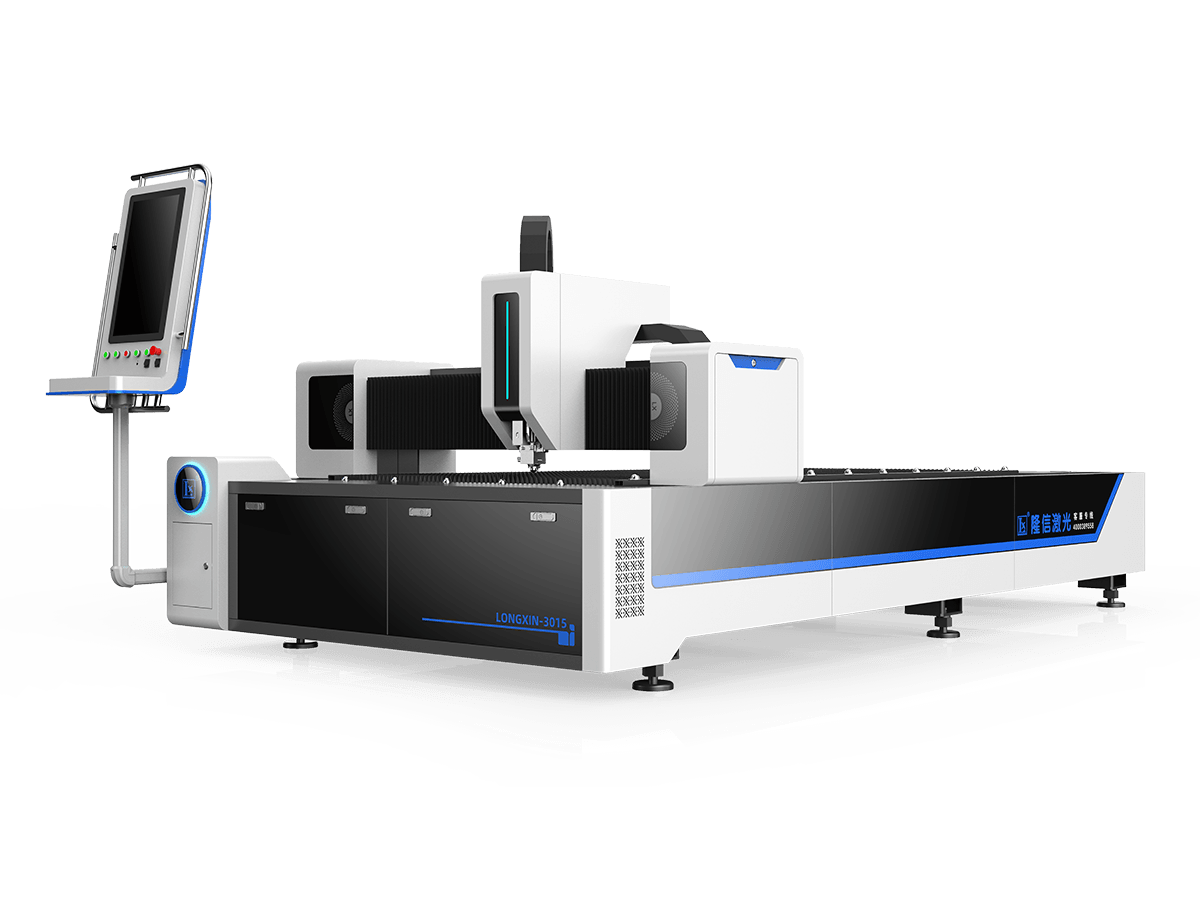

2D laser cutting, also known as flatbed cutting, utilizes a highly focused laser beam to cut flat materials like steel, stainless steel, aluminum, and non-ferrous metals with precision.

The process involves a laser resonator that creates a beam directed towards a cutting head, focusing through a lens to melt, burn, or vaporize the material.

Typically, these machines have three axes: two for positioning and one Z-axis to adjust the cutting head’s distance from the workpiece.

Applications and Materials

2D laser cutting is pivotal for industries requiring precision in cutting thin metal sheets. It is widely used for materials such as mild steel, stainless steel, aluminum, copper, and brass, with thicknesses ranging from 0.8 mm to 30 mm.

Its applications extend to industrial manufacturing, schools, small businesses, and hobbyists.

利点と欠点

メリット:

- High precision and quality cuts with an accuracy of +/-0.1 mm.

- Fast processing speeds, reducing manual labor and operational costs.

- Minimal thermal distortion, ensuring clean cuts and reducing post-processing needs.

デメリット:

- Limited to cutting materials up to 25 mm in thickness.

- High energy consumption and significant initial equipment costs.

- Requires adequate ventilation due to harmful gases and fumes produced during cutting.

Understanding 3D Laser Cutting

Definition and Process

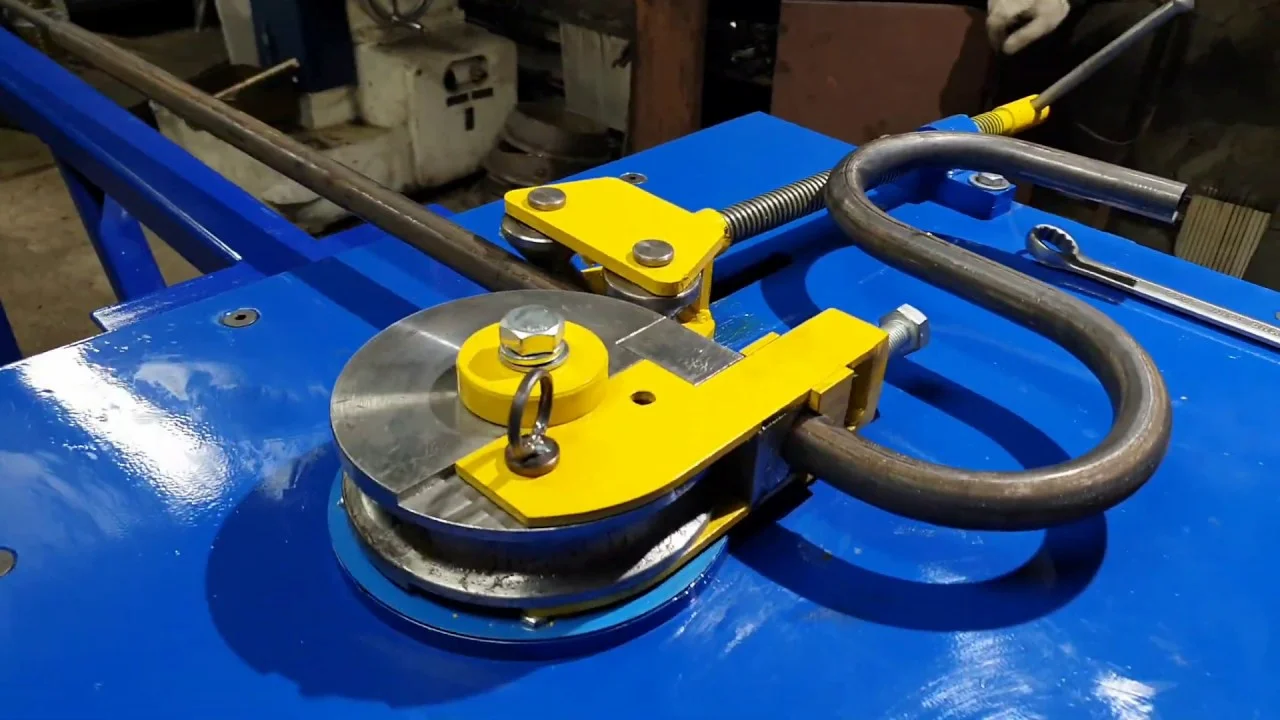

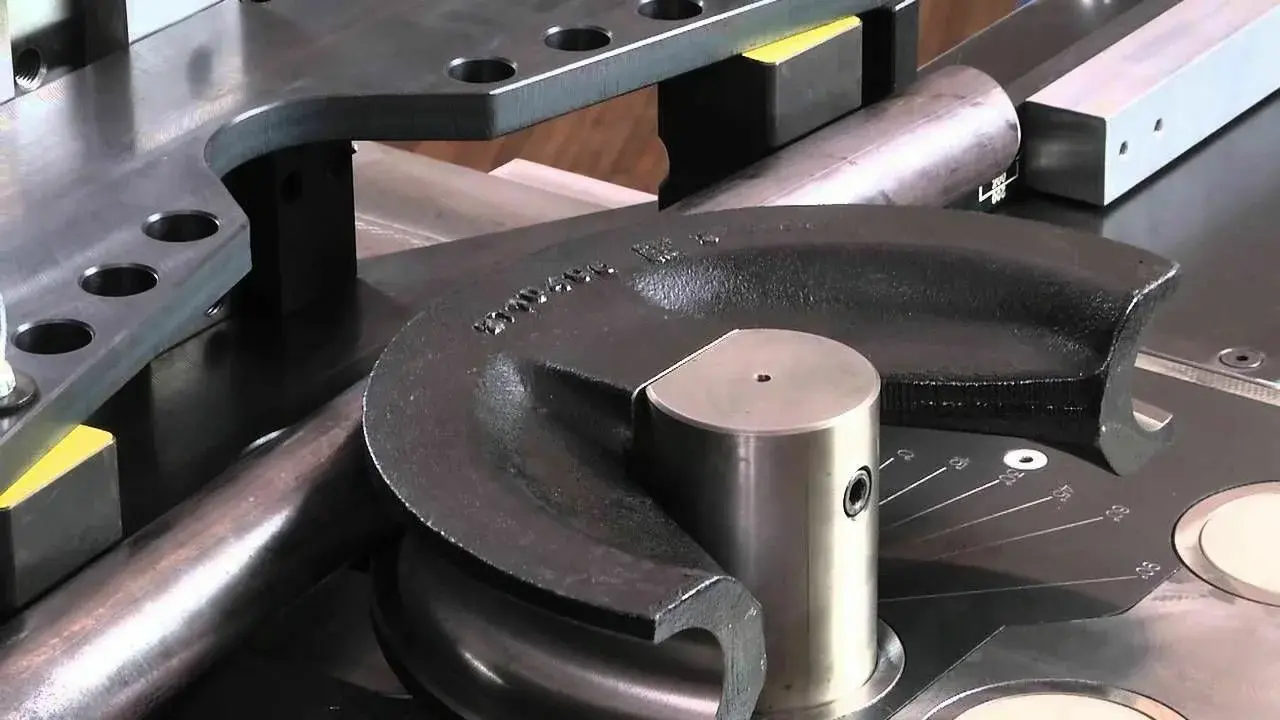

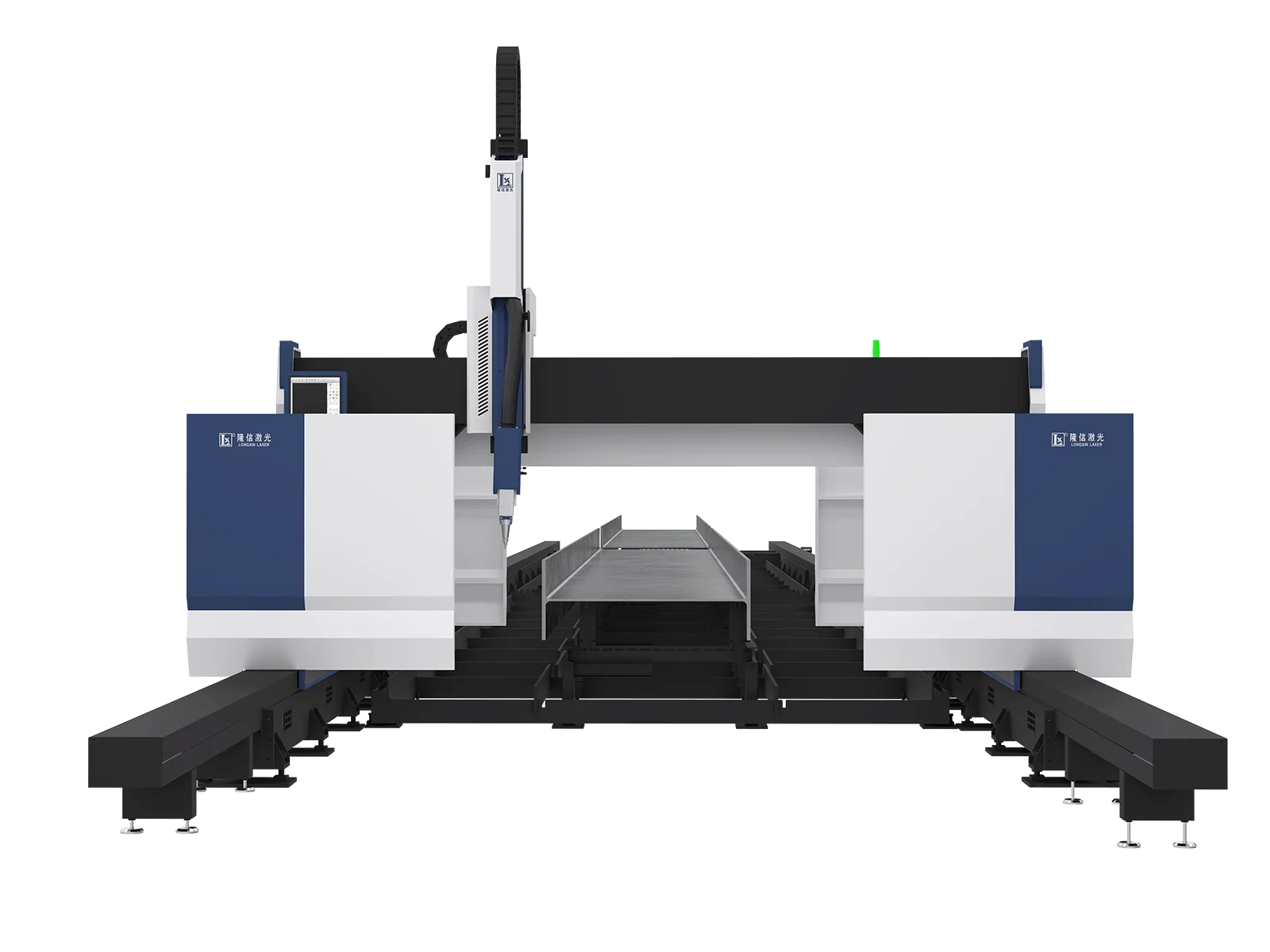

3D laser cutting uses a focused laser beam directed by a complex system moving along multiple axes, allowing intricate cuts on various material surfaces.

This method involves a rotary head that adjusts to the contours of the material, maintaining optimal distance and angle for precise cutting.

Applications and Materials

3D laser cutting is particularly advantageous for industries requiring high precision for complex parts, such as aerospace, automotive, and electronics.

It can cut metals like stainless steel and aluminum, as well as other industrial materials, to create custom shapes and designs up to 20 mm thick.

利点と欠点

メリット:

- High efficiency and speed, surpassing traditional cutting methods.

- Precision cutting with minimal heat-affected zones and less material waste.

- Versatility in handling various material profiles and thicknesses.

デメリット:

- High initial investment and power consumption.

- Intensive maintenance requirements, particularly for certain lasers like CO2.

- Safety concerns due to hazardous fumes necessitating proper ventilation.

Key Differences Between 2D and 3D Laser Cutting

| Aspect | 2D Laser Cutting | 3Dレーザー切断 |

|---|---|---|

| Capability | Cuts flat, two-dimensional shapes | Cuts intricate, three-dimensional shapes |

| Precision | High precision on flat materials | High precision across multiple axes |

| Material Handling | Limited to flat, consistent thickness materials | Handles various shapes, sizes, and thicknesses |

| Cost | Lower initial investment, suitable for simpler projects | Higher initial investment, suitable for complex projects |

| Applications | Signage, metal components, parts manufacturing | Aerospace, automotive, electronics, medical equipment, architecture |

結論

Understanding the differences between 2D and 3D laser cutting technologies is essential for making informed decisions in manufacturing and design. While 2D laser cutting offers simplicity, precision, and cost-effectiveness for flat materials, 3D laser cutting provides unmatched flexibility for intricate three-dimensional shapes and complex geometries.

Selecting the appropriate technology ensures optimal performance, cost-efficiency, and innovation in your projects, pushing the boundaries of what’s achievable in modern manufacturing.