Laser cutting is widely regarded as one of the most precise and efficient metal processing technologies available today. Yet for many buyers, the first quotation can be surprising — or even shocking. Whether you are outsourcing parts or evaluating a laser cutting machine for your own factory, one question almost always comes up:

Why is laser cutting so expensive?

The short answer is: the price reflects far more than just “cutting metal.” The long answer involves capital equipment, energy consumption, assist gases, skilled labor, precision requirements, and long-term operational economics. This article breaks down the real costs behind laser cutting — and explains when it is actually the most cost-effective solution.

The High Capital Cost of Laser Cutting Machines

At the core of laser cutting pricing is the machine itself. An industrial laser cutting machine is not a simple tool; it is a complex system combining optics, electronics, motion control, software, and heavy mechanical engineering.

- A modern fiber laser cutting system typically includes:

- A high-power fiber laser source

- Precision CNC motion systems and servo drives

- A rigid, stress-relieved machine bed

- Intelligent cutting heads with auto-focus and collision protection

- Cooling, dust extraction, and safety systems

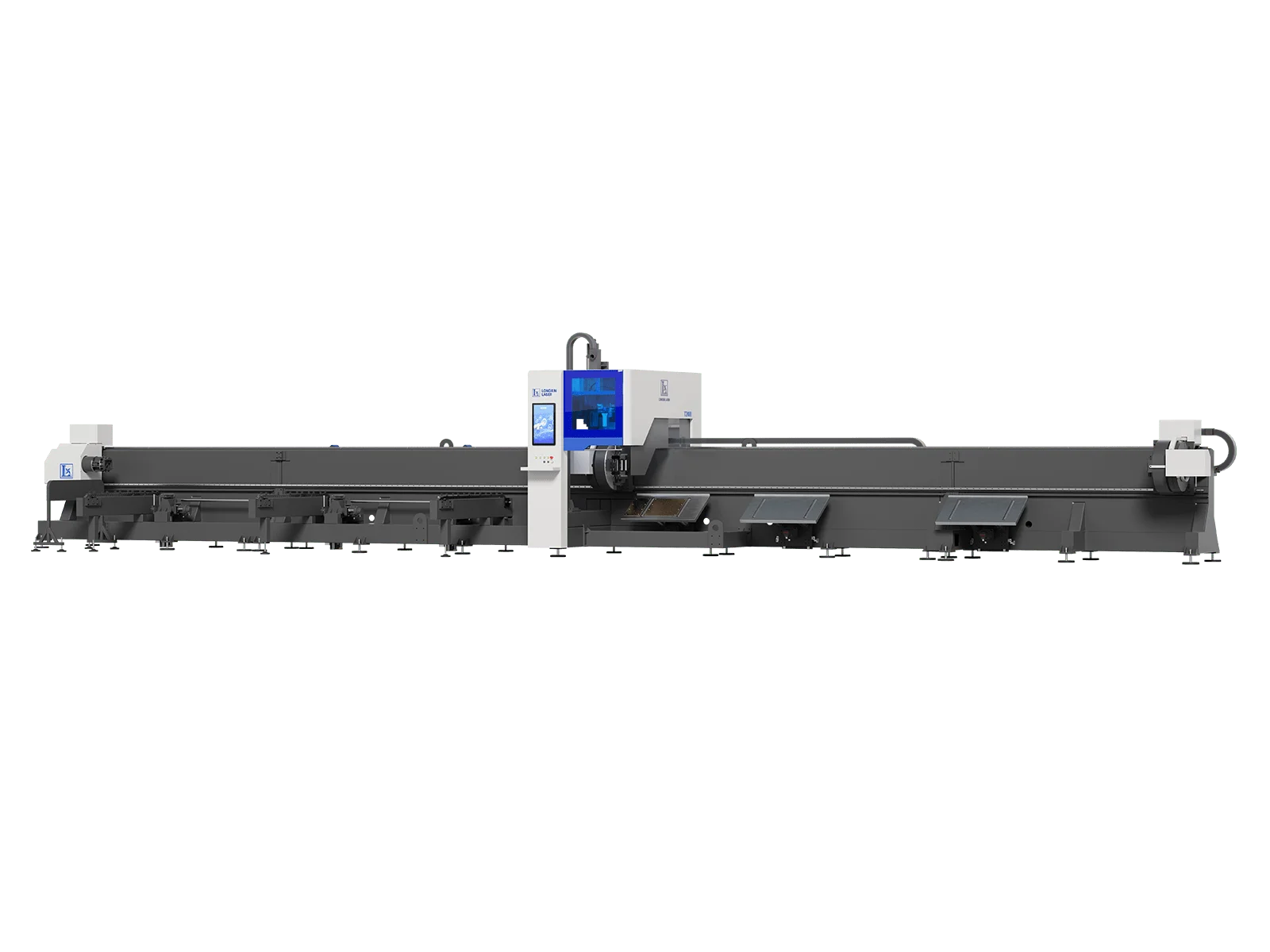

Each of these components is manufactured to extremely tight tolerances. Maintaining positioning accuracy at the micron level requires high-grade materials, advanced machining, and strict quality control. This is especially true for large-format sheet machines and specialized systems like the laser pipe cutting machine, where rotary accuracy and synchronization add another layer of complexity.

Unlike conventional mechanical equipment, laser systems also rely heavily on photonics technology. High-quality laser sources are designed for long service life, stable output, and high electrical efficiency — all of which increase upfront investment but reduce long-term operating risk.

Energy Consumption and Assist Gas Costs

Beyond the machine itself, laser cutting has ongoing operational costs that are often invisible to buyers.

Electricity Usage

While modern fiber lasers are significantly more energy-efficient than older CO₂ systems, high-power cutting still consumes substantial electricity. A 6–12 kW laser running multiple shifts per day represents a meaningful energy expense, especially in regions with high industrial electricity rates.

However, higher electrical efficiency is also why many manufacturers upgrade their equipment: faster cutting speeds mean lower energy consumption per part, even if peak power is higher.

Assist Gases: Oxygen, Nitrogen, and Air

- Assist gas choice has a major impact on cutting cost:

- Oxygen is commonly used for carbon steel. It is relatively inexpensive and increases cutting speed through exothermic reaction.

- Nitrogen is required for stainless steel, aluminum, and applications where oxidation is unacceptable. Nitrogen is significantly more expensive, particularly at high pressures.

Compressed air can be a low-cost alternative for thin materials and non-critical parts.

For shops processing stainless steel or aluminum at scale, nitrogen consumption can become one of the largest recurring costs — sometimes exceeding electricity expenses. This is one reason many high-volume users invest in on-site nitrogen generation systems.

|

Gas Type

|

Thermodynamic Role

|

Pressure Level

|

Relative Cost

|

|---|---|---|---|

|

Oxygen (O2)

|

Exothermic (Adds heat)

|

Low (2–6 bar)

|

Low: $2 – $5 per hour

|

|

Nitrogen (N2)

|

Inert (Mechanical removal)

|

High (10–25 bar)

|

High: $15 – $25 per hour

|

|

Compressed Air

|

Hybrid (78% N2, 21% O2)

|

High (16–20 bar)

|

Efficient: $1 – $2 per hour

|

Material Type and Thickness Matter More Than You Think

Not all laser cutting jobs are equal. Material selection dramatically affects cutting speed, gas consumption, and wear on consumables.

Key cost factors include:

- Material type: Stainless steel and aluminum require inert gas; copper and brass are highly reflective and demand advanced optics and process control.

- Thickness: Cutting speed decreases non-linearly as thickness increases, raising machine time per part.

- Surface condition: Rust, coatings, or inconsistent material quality can slow production and increase scrap rates.

For tube and profile processing, these variables become even more important. A 레이저 파이프 절단기 must handle different diameters, wall thicknesses, and shapes while maintaining rotational accuracy, which directly impacts cycle time and cost.

Precision, Tolerance, and Edge Quality Are Part of the Price

Laser cutting is often chosen not because it is cheap, but because it is accurate.

Typical industrial laser systems can achieve:

- High positional accuracy and repeatability

- Clean, narrow kerfs

- Minimal thermal distortion

- Excellent edge quality

This level of precision often eliminates secondary operations such as grinding, deburring, or manual fitting. When evaluating cost, it is critical to consider not just the cutting price, but the total process cost. In many cases, laser cutting reduces overall labor hours and improves consistency across large production runs.

Skilled Labor, Programming, and Setup Time

Despite automation, laser cutting is not a “push-button” process. Skilled human expertise is embedded in every quote.

Labor costs include:

- CAD/CAM programming and nesting optimization

- Parameter tuning for new materials or thicknesses

- Machine setup, loading, and unloading

- Preventive maintenance and troubleshooting

For small batches or prototypes, setup and programming time may represent a significant portion of the total price. In contrast, high-volume production benefits from amortized setup costs, making laser cutting far more economical per part.

Consumables, Maintenance, and Downtime Risk

Laser cutting systems rely on consumables that must be replaced regularly:

- Protective lenses and nozzles

- Filters for dust and fume extraction

- Cooling system components

In addition, unplanned downtime carries a real financial risk. Optics damage, chiller failure, or alignment issues can be expensive if not managed proactively. This is why many professional shops factor preventive maintenance and service contracts into their hourly cutting rates.

Low Volume vs Mass Production Economics

One of the biggest reasons laser cutting seems expensive is order volume.

- Low volume / custom jobs:

Setup, programming, and machine time are concentrated into a small number of parts, resulting in high unit prices. - Mass production:

Once a process is optimized, laser cutting becomes extremely efficient. High speed, consistent quality, and automation drive unit costs down rapidly.

For companies with steady demand, investing in their own laser cutting machine — or even a dedicated laser pipe cutting machine — can dramatically reduce long-term costs and lead times.

Total Cost of Ownership: When Laser Cutting Is Actually Cheaper

When evaluated correctly, laser cutting often outperforms alternative methods in total cost of ownership (TCO). Factors contributing to lower TCO include:

- Reduced material waste through optimized nesting

- Fewer secondary operations

- Higher repeatability and lower scrap rates

- Faster turnaround and better production planning

In other words, laser cutting may appear expensive on a per-hour basis, but it often delivers the lowest cost per finished part.

How to Reduce Laser Cutting Costs

- Choose the right laser power instead of oversizing equipment

- Optimize part design to reduce cutting length and pierces

- Batch similar jobs to minimize setup time

- Select the most appropriate assist gas strategy

- Invest in automation where volume justifies it

- Evaluate in-house production versus outsourcing using TCO, not hourly rates

Frequently Asked Questions

Is laser cutting more expensive than plasma cutting?

Laser cutting typically has higher equipment and hourly costs but delivers superior precision and edge quality. For thin to medium thickness materials requiring accuracy, laser cutting often has a lower total cost.

Why is stainless steel laser cutting more expensive?

Stainless steel usually requires nitrogen assist gas to prevent oxidation, increasing gas consumption and cutting cost.

Does laser power affect cutting cost?

Yes. Higher power increases cutting speed but also increases equipment investment. The most cost-effective solution is matching power to your typical material thickness and production volume.

Is it cheaper to buy a laser cutting machine or outsource?

Outsourcing is usually cheaper for low volumes or irregular demand. For consistent production, owning a laser cutting machine can provide faster ROI and better cost control.

How much does laser cutting cost per hour?

Rates vary widely depending on machine type, power, material, gas, and labor costs. Comparing itemized quotes and focusing on total process cost is more reliable than hourly rates alone.

Final Thought

Laser cutting is expensive only if viewed in isolation. When precision, efficiency, and downstream savings are considered, it often becomes the smartest manufacturing investment available.

참고문헌

Authoritative sources and further reading: