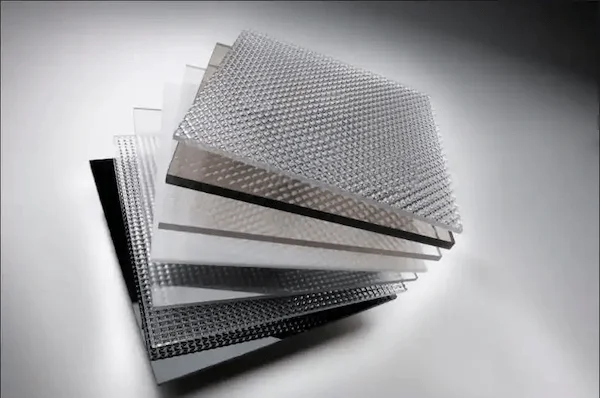

Polycarbonate sheets (PC sheets) are high-performance engineering plastics known for their strength, transparency, and impact resistance. They are widely used in architecture, electronics, and automotive manufacturing—for example, in skylights, sound barriers, headlamp covers, electronic device shields, LCD protectors, and housing enclosures.

1. Is Laser Cutting Polycarbonate Possible?

Traditionally, polycarbonate was considered unsuitable for laser cutting due to the potential release of toxic gases (e.g., hydrogen cyanide) during processing. However, recent advancements show that under specific conditions, polycarbonate can be laser cut effectively. Achieving quality results depends on selecting the right laser type, adjusting processing parameters, and applying auxiliary techniques.

2. Suitable Laser Types

Ultraviolet (UV) Laser – ~355 nm wavelength

-

Advantages: Cold processing with minimal heat-affected zone; photons directly break molecular bonds, enabling precise, clean cuts without yellowing.

-

Best for: Micro-perforation, ultra-thin sheets, or fine contour work.

CO₂ Laser – 10.6 μm wavelength

-

Advantages: Well-suited for non-metal sheet cutting via thermal evaporation. Can cut thicker PC sheets when power is carefully managed.

-

Important Note: Use assist gas (e.g., compressed air) for cooling to minimize yellowing or edge burning.

3. Recommended Laser Cutting Equipment

CO₂ Laser Cutter

-

Recommended Wavelengths: 9.3 μm or 10.6 μm

-

Applications: Cutting standard PC sheet thicknesses (1–20 mm)

-

Benefits: Cost-effective and widely used; must be paired with an air or nitrogen assist system to cool the cutting zone.

UV Laser Cutter (optional)

-

Wavelength: 355 nm

-

Applications: High-precision cutting of ultra-thin PC sheets (<1 mm) or micro-holes with zero thermal damage.

Conclusion: Use CO₂ lasers for efficient cutting of most PC sheets; opt for UV lasers in high-precision, low-heat applications.

4. Recommended Laser Cutting Parameters for PC Sheets

| Parameter | Recommended Setup |

|---|---|

| Power & Speed | – ≤5 mm thickness: 300–500 W @ 10–30 mm/s – >5 mm thickness: 800–1000 W @ 5–15 mm/s (layered cutting advised) |

| Assist Gas | Nitrogen or compressed air at 0.3–0.5 MPa to prevent edge charring |

| Nozzle Type | Single-layer nozzle (1.5–2.0 mm diameter) to reduce material adhesion |

| Focus Settings | Focus on sheet surface; spot diameter ≤0.1 mm for accuracy |

5. Laser Cutting Workflow for Polycarbonate Sheets

(1) Equipment Setup

-

Start in sequence: Power stabilizer → Chiller → Air compressor → Laser → CNC system → Gas pressure regulator

-

Use pulse test (spot fire) to align the laser head and center the beam.

(2) File Preparation

-

Import CAD/DXF files into CNC software (e.g., cncKad), check and repair contour gaps.

-

Cutting order: prioritize small holes and intricate patterns before outer frames.

(3) Cutting Execution

-

Use “Frame” function to confirm cutting area.

-

Activate gas flow, then press “Start/Pause” to begin cutting.

-

For thicker sheets, apply multi-pass (layered) cutting to prevent thermal stress cracks.

6. Key Precautions

-

Material Pre-Treatment: If the PC sheet has a UV coating, cut from the coated side to reduce warping.

-

Ventilation & Safety: Toxic cyanide gases may be released during cutting—use powerful exhaust systems. Never cut PVC-modified PC sheets.

-

Maintenance: Drain the air compressor daily to prevent condensation from clogging air lines.

7. Troubleshooting

| Symptom | Likely Cause | Solution |

|---|---|---|

| Edge yellowing/burning | Excessive power or insufficient gas | Reduce power (<500 W); increase air pressure or switch to UV laser |

| Incomplete kerf | Misaligned focus or speed too high | Recalibrate beam alignment; lower speed |

| Bubbling on cut surface | Moisture or contamination in material | Preheat sheet (60°C for 2 hrs) or switch material |

8. Alternative Cutting Methods for PC Sheets

Circular Saw Cutting

A standard technique for PC sheets. According to Steyr Mechanical Research, using a 300 mm, 80–100-tooth carbide blade at 2800–3200 rpm offers optimal results. Compressed air cooling is recommended to keep cutting temperature below 80°C and prevent warping.

Oscillating Knife Cutting

AMADA’s VZ series uses high-frequency (200 Hz), low-amplitude (0.1–0.3 mm) blades with diamond-coated edges. Achieves up to 0.05 mm precision—ideal for sheets <3 mm in electronics manufacturing.

Waterjet Cutting

Non-thermal method ideal for thick PC sheets. IVY CNC found that a 380 MPa abrasive waterjet with a 0.3 mm nozzle can cut up to 150 mm thick PC with ±0.1° edge verticality. Increases material utilization by 15–20%, ideal for complex shapes.

9. Conclusion & Recommendations

Polycarbonate cutting methods are diversifying. Each technique offers trade-offs in precision, efficiency, and cost:

-

For standard applications: Use circular saw cutting as the base method.

-

For high-precision needs: Combine oscillating knife for accuracy.

-

For complex/high-value parts: Choose waterjet cutting to maximize material use.

-

For thin, precise cuts: Laser cutting is viable, but only with proper exhaust systems and parameter control.