Pipe laser cutting machines are essential equipment in modern manufacturing, widely used in industries such as automotive, aerospace, construction, and furniture production. For buyers considering a pipe laser cutting machine, pricing in 2025 can appear complex and widely varied. This blog analyzes recent listings from leading global brands and B2B platforms to provide a realistic overview of current price tiers—ranging from entry-level to advanced systems. We aims to help potential buyers make informed budget decisions by combining market data with observed trends.

Price Tiers and Configuration Differences

Pipe laser cutting machines are categorized into three main price tiers based on their configuration and capabilities: entry-level ($15,000 to $40,000), mid-range ($50,000 to $100,000), and high-end ($150,000 and above). Below are the typical configurations and applications for each tier.

Entry-Level ($15,000 to $40,000)

Laser Power:

These machines pack a punch with 1.5kW to 3kW lasers, which is just right for slicing through thinner stuff—anything under 8mm thick. Think stainless steel, carbon steel, or aluminum. They’re perfect if you’re working on lighter materials and don’t need to go heavy-duty.

Pipe Handling Capacity:

You can work with round, square, or rectangular pipes here, ranging from 10mm to 120mm in diameter. They’ll take pipes up to 6 meters long and weighing around 100kg max. It’s a solid setup for smaller jobs, like crafting metal bits for furniture or simple pipe parts.

Automation:

No fancy robotics here—just manual loading or a basic CNC feeding system. It’s simple to use and great for small batches, so if you’re not churning out tons of pieces, this keeps things easy and manageable.

Precision:

They’re pretty accurate for the price, hitting about ±0.05mm for positioning and ±0.03mm when repeating cuts. That’s more than enough for straightforward tasks where you don’t need super-fine detail.

Software:

The software’s basic but does what you need for simple shapes and contours. It’s user-friendly, so you won’t be scratching your head trying to figure it out—ideal for quick, no-frills designs.

Applications:

These are a great fit for small workshops or anyone doing low-volume work. Picture making metal legs for chairs or basic pipe components—nothing too complicated, just practical stuff.

Example Models:

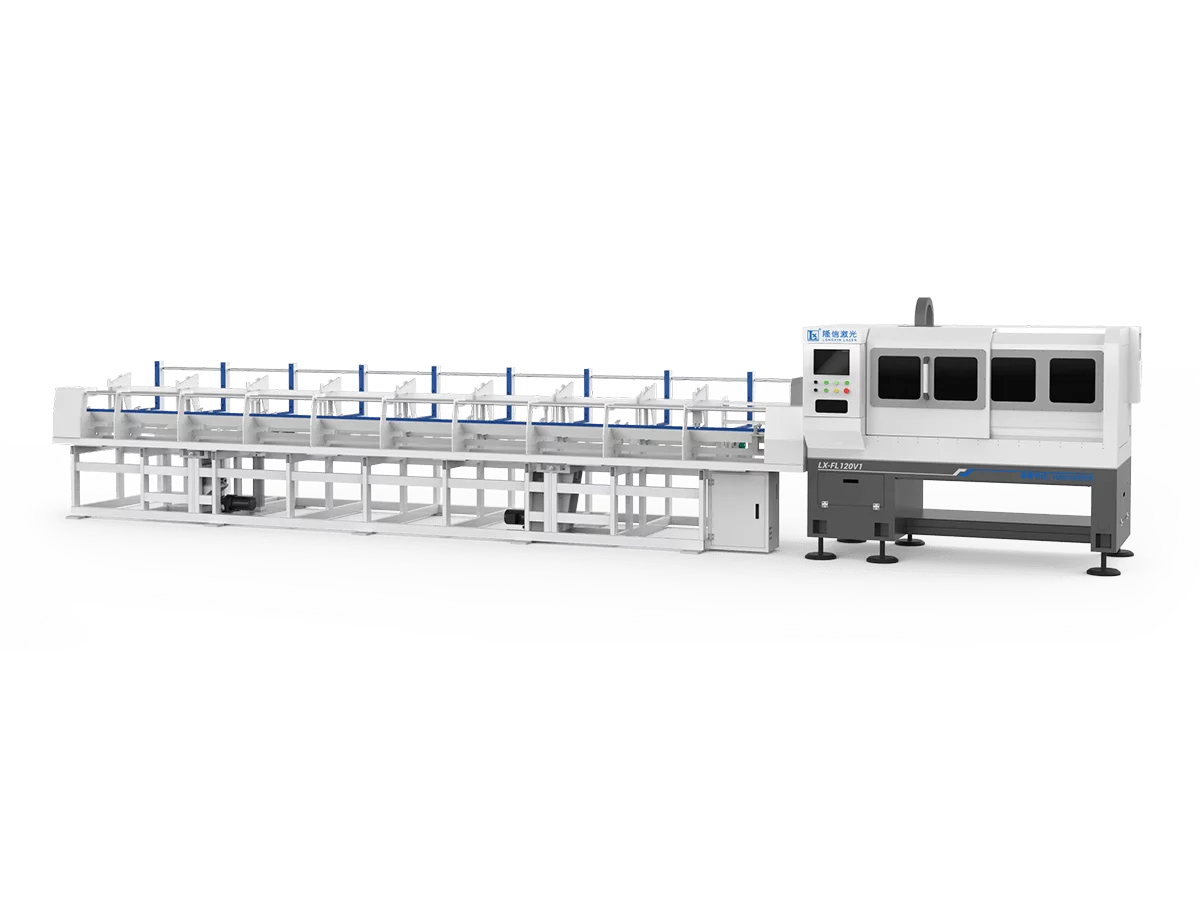

- Longxin Laser LX-FL120: ($15,000 to $30,000) Entry-level laser tube cutting machine designed specifically for cutting round tubes.

- Shandong Fast CNC 1.5kW: Around $19,950 (FOB)—a reliable choice for small businesses starting out.

- STYLECNC ST-FC6012T (1500W): About $20,800, handling pipes from 10mm to 120mm with ease.

Mid-Range ($50,000 to $100,000)

Laser Power:

Stepping up, you’ve got 4kW to 6kW lasers that can tackle medium-thick materials—think 5mm to 10mm—at a quicker pace. They’re perfect for steel or aluminum when you need a bit more oomph than entry-level offers.

Pipe Handling Capacity:

These machines handle pipes from 15mm to 230mm in diameter and up to 6 meters long, with a weight limit of about 300kg. That’s a nice range for things like structural profiles or medium-sized production runs.

Automation:

Here’s where it gets smoother—automatic loading and unloading systems, plus fixed chucks, make your workflow faster and less hands-on. It’s a big help if you’re scaling up production a bit.

Precision:

The accuracy bumps up too, giving you tighter positioning and repeat cuts. It’s just what you need for jobs that are a little more detailed but not over-the-top complex.

Software:

You get advanced nesting and programming tools with this tier, which is awesome for squeezing the most out of your materials. It’s a step up from basic, letting you plan smarter cuts.

Applications:

These shine in medium-sized workshops where you might be making structural parts or running medium batches. They’re versatile enough to keep things moving without costing a fortune.

Example Models:

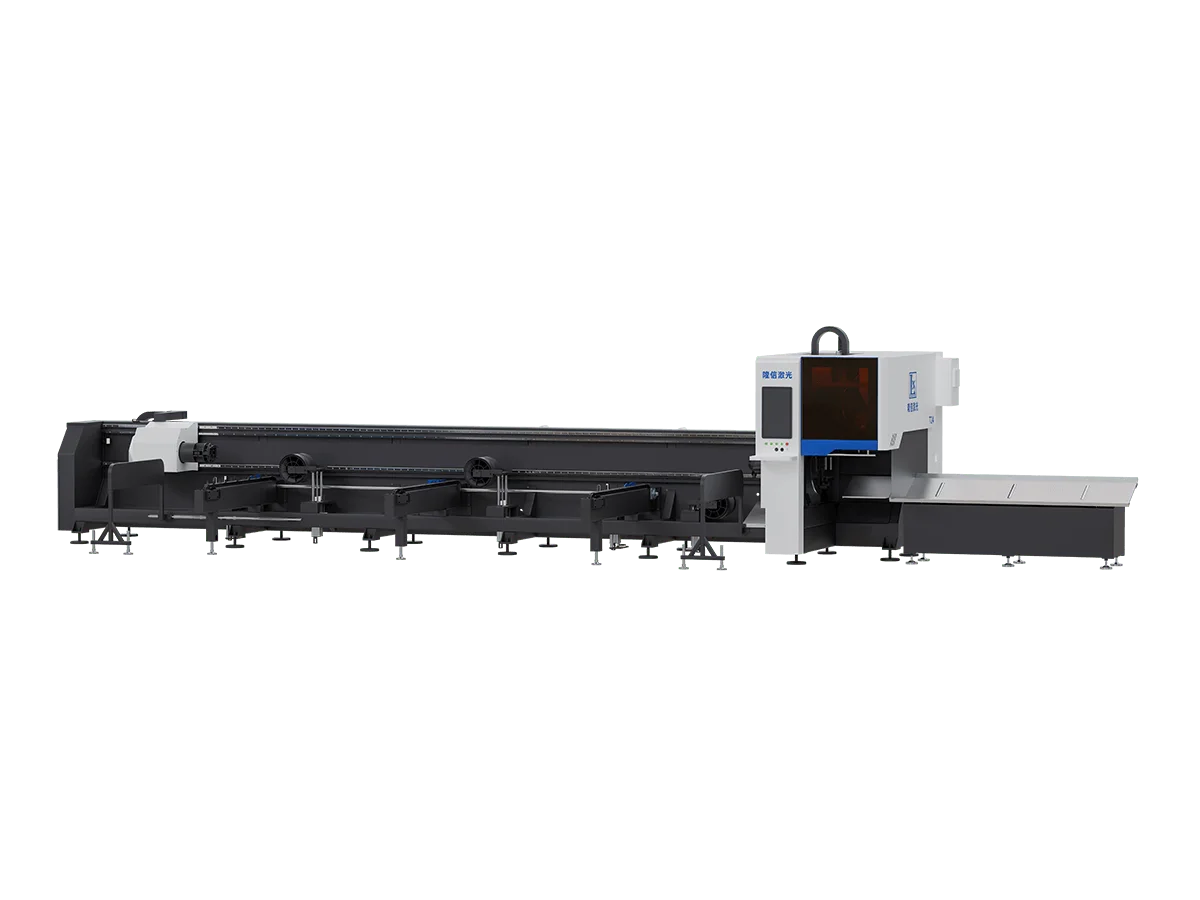

- Longxin Laser LX-T24: ($50,000 to $75,000) Heavy duty tube laser cutting with bevel cut process.

- Bodor K-Series 6kW: ($60,000 to $75,000) — great for steady, medium-scale work.

High-End ($150,000 and Above)

Laser Power:

These beasts start at 6kW and go up to 12kW or more, cutting through thick materials—over 10mm—like butter, and fast. If you’re dealing with heavy steel or aluminum, this is your go-to.

Pipe Handling Capacity:

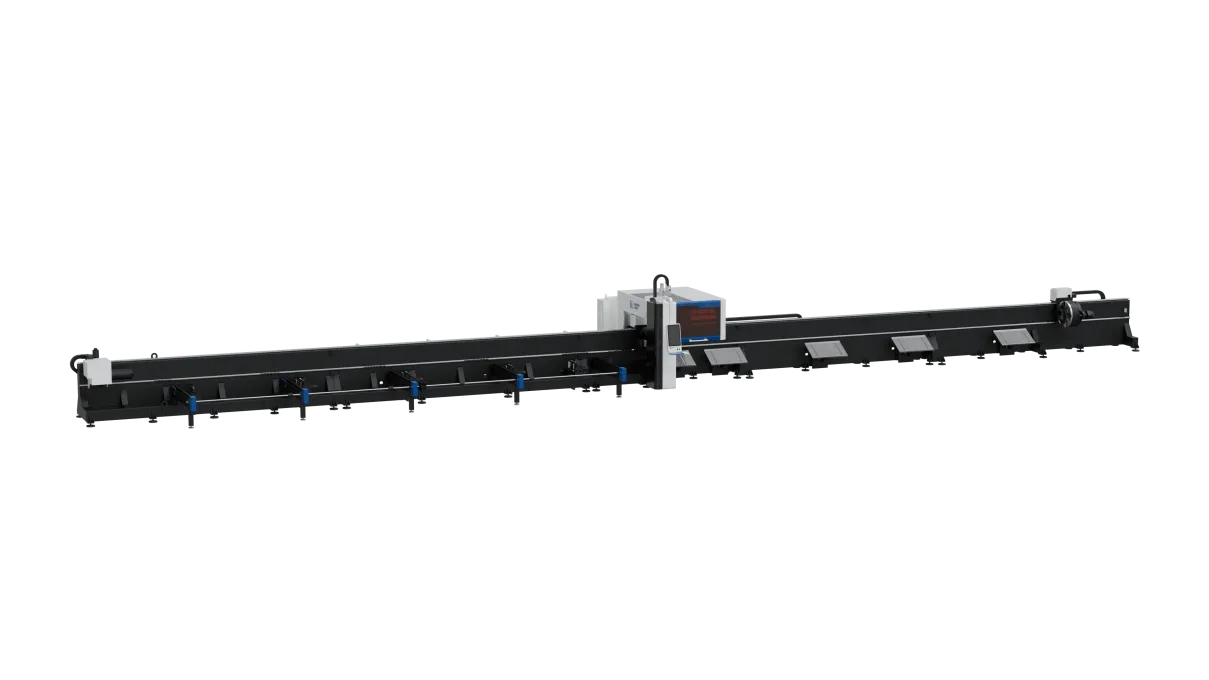

They can take on pipes from 20mm to 350mm (or even bigger), stretching up to 12 meters or longer, and handling weights up to 900kg. It’s built for the big, tough jobs that demand serious capacity.

Automation:

This is where it’s fully hands-off—multi-axis cutting heads, robotic loaders, and long pipe conveyor systems keep everything running smoothly. It’s like having a production line on autopilot.

Precision:

You’re looking at ±0.03mm accuracy or better, which is incredible for tricky cuts like bevels or complex patterns. It’s the kind of precision that makes a difference on high-stakes projects.

Software:

The CAD/CAM software here is top-notch, integrating complex designs and production management seamlessly. It’s perfect for juggling detailed work and big workloads without breaking a sweat.

Applications:

These are made for the heavy hitters—aerospace, shipbuilding, infrastructure—where you can’t compromise on quality or speed. They’re the real deal for demanding industries.

Example Models:

- Longxin Laser LX-T35-3: (Starting at $150,000) Three-chuck tube laser bevel cutting machine, customizable 6/9/12/24m loading/unloading per your needs.

- Trumpf TruLaser Tube 5000 (4kW, used): Around $550,000, loaded with advanced features.

- BLM Group Lasertube: Between $180,000 and $300,000, tackling pipes up to 610mm.

Configuration Differences Table

| Tier | Power Range | Typical Features | Price Range (USD) |

|---|---|---|---|

| Entry-Level | 1.5–3 kW | Manual/basic CNC, simple tube handling | $15,000–$40,000 |

| Mid-Range | 4–6 kW | Automated loading, fixed chucks, mid-speed | $50,000–$100,000 |

| High-End | 6–12 kW+ | Multi-axis, robotic loaders, long tubes | $150,000–$300,000+ |

Why Pipe Laser Cutting Machines Vary So Much in Price and Features

Ever wondered why some pipe laser cutting machines are priced at $15,000 while others soar into the hundreds of thousands? It’s not just random—it comes down to a handful of practical factors that shape what you get for your money. Let’s dive in.

Laser Power and Cutting Speed: The Muscle Behind the Machine

- Higher laser power (e.g., 6kW vs. 3kW) requires more expensive laser sources and cooling systems, directly increasing the machine’s cost.

- For cutting materials thicker than 10mm, a laser power of 6kW or higher is recommended, enabling faster processing of thick materials.

Pipe Handling Capacity: Bigger Pipes, Bigger Challenges

- Handling larger diameters or longer pipes requires stronger chucks, servo motors, and frames, which increase manufacturing costs.

- For example, high-end machines can handle pipes over 350mm in diameter, while entry-level machines are limited to 120mm.

Automation and Accessories: Work Smarter, Not Harder

- Automatic loading and unloading systems, rotary chucks, and multi-axis cutting heads add complexity to the mechanical and control systems, increasing costs by $20,000 to $100,000.

- High-end machines often include robotic loaders and long pipe conveyors, significantly boosting efficiency.

Laser Source Brand: Trust Costs Extra

- Well-known brands like IPG and Raycus offer more reliable performance but are more expensive than generic modules.

- For instance, an IPG laser source may cost 20-30% more than a standard brand.

Precision and Control Systems: Nailing Every Detail

- High precision requires premium linear guides, high-performance servo motors, and advanced CNC systems, which raise costs.

- Advanced software supports complex designs and efficient nesting, optimizing material usage.

Manufacturer Reputation and Support: The Brand Bonus

- European brands like Trumpf and Bystronic typically charge 20-30% more than Chinese brands due to their reliability and superior after-sales service.

How to Choose the Right Pipe Laser Cutting Machine

Choosing the right machine isn’t just about cash—it’s about finding the one that fits your needs like a glove. Here’s how to sort it out, step by step.

Step 1: Figure Out What You’re Cutting

-

Material and Thickness: What’s on your plate—stainless steel, aluminum, carbon steel? How thick? Thin pipes under 5mm are fine with 1.5kW to 3kW lasers. Over 10mm? You’re looking at 6kW or more.

-

Pipe Size: How big are your pipes? Under 120mm in diameter? Entry-level works. Over 230mm? Time for mid-range or high-end.

-

Production Volume: How much are you cutting daily or weekly? Big batches need more power and automation to keep up.

-

Complexity: Want cool bevels or intricate designs? Go for machines with multi-axis heads and smart cutting tech.

Step 2: Get the Lowdown on Specs

-

Laser Power: Match it to your material thickness. Low power for thin pipes, high power for thick ones or fast production.

-

Pipe Handling: Make sure it can manage your biggest pipes—size and weight included.

-

Automation: High volume? Auto systems are a lifesaver. Small runs? Manual might do.

-

Precision: Check the accuracy stats if your cuts need to be perfect.

-

Software: Good software makes designing and minimizing waste a breeze. Don’t skip it.

Step 3: Crunch the Numbers

-

Initial Cost: Entry-level starts at $15,000, mid-range at $50,000, high-end at $150,000+. Pick what your budget can handle.

-

Operating Costs: Factor in maintenance, parts like laser heads, and power bills. Fiber lasers cost more upfront but save cash long-term compared to CO2.

-

Total Cost: Add up everything—buying, setup, training, upkeep. It’s the full picture that counts.

Step 4: Pick a Brand You Can Count On

-

Reputation: Names like TRUMPF or BLM Group scream quality. Bodor or Golden Laser from China? Great value.

-

Support: Check for solid after-sales help and easy spare parts access.

-

Try Before You Buy: Ask for samples or a demo to see what the machine can really do.

Quick Decision Guide

Stuck on where to start? Here’s a fast way to narrow it down:

-

Maximum Pipe Diameter?

-

<120mm: Consider entry-level or mid-range machines.

-

120-230mm: Mid-range machines.

-

230mm: High-end machines.

-

-

Maximum Wall Thickness?

-

<5mm: 1.5kW-3kW.

-

5-10mm: 3kW-6kW.

-

10mm: 6kW or higher.

-

-

Automation Needed?

-

No: Entry-level machines.

-

Yes: Mid-range or high-end machines.

-

-

Budget?

-

<$40,000: Entry-level.

-

$50,000-$100,000: Mid-range.

-

$150,000: High-end.

-

Market Trends and Regional Variations

-

Global Trends: The price of fiber laser pipe cutting machines has decreased by approximately 10% over the past three years, driven by improved manufacturing efficiency in China.

-

Growth Forecast: The market is expected to grow from $1.2 billion in 2024 to $2.7 billion by 2033.

-

Regional Price Differences: Prices in North America and Europe are 10-20% higher due to shipping, tariffs, and after-sales service costs, while the Asia-Pacific region remains the most competitive.

Best Practices

-

Define Requirements: Clearly specify the maximum pipe length, diameter range, and material thickness before purchasing to avoid overspending on unnecessary features.

-

Compare Quotes: Ensure that quotes include the same laser source brand, automation package, warranty, and installation services.

-

Total Cost of Ownership: Consider maintenance contracts, gas consumption (for CO2 lasers), electricity usage, and consumables costs.

-

On-Site Visits: Attend industry exhibitions or visit manufacturer showrooms to see the machines in operation.

Conclusion

By understanding the price and configuration differences of pipe laser cutting machines, buyers can better align their budget with production goals. Entry-level machines start at $15,000, mid-range at $50,000 to $100,000, and high-end at $150,000 and above. It is recommended to request detailed quotes, include service terms, and compare multiple manufacturers to secure the best value.