Tube laser cutting machines

Laser cutting machines for tubes come in various configurations

Equipped with up to 2.0 G acceleration and advanced AI‑driven multi‑axis control, our tube laser cutting machine delivers unparalleled throughput, sub‑millimeter accuracy, and engineered durability—minimizing waste by up to 9% and ensuring reliable performance in aerospace, automotive, and heavy‑duty production environments.

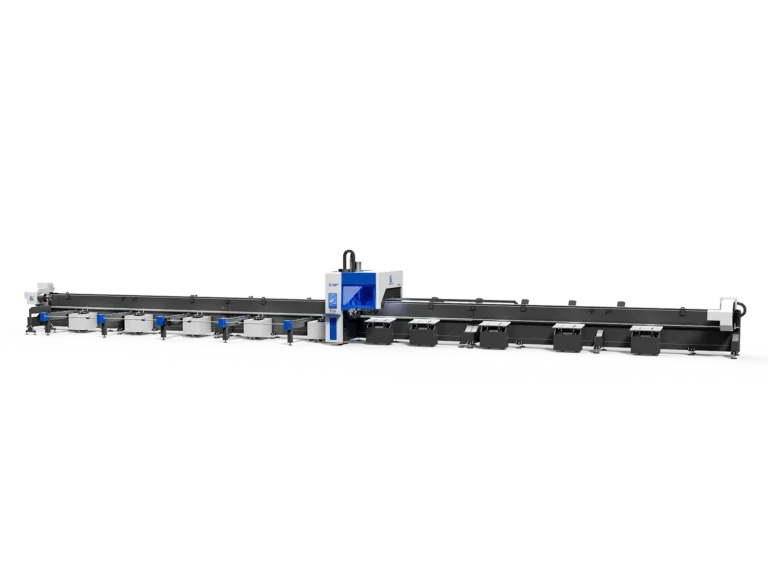

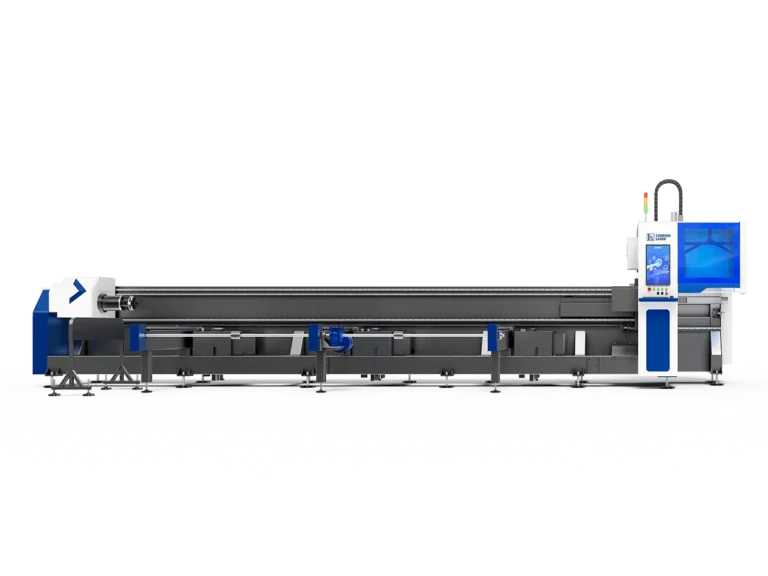

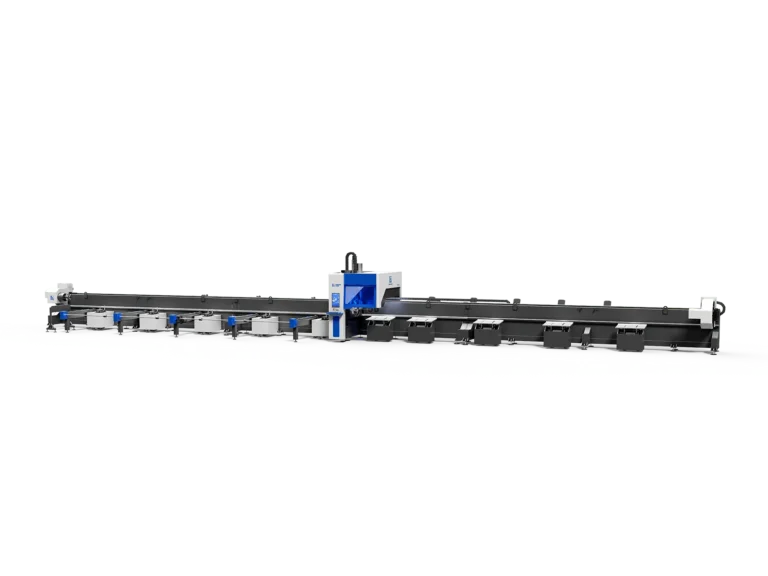

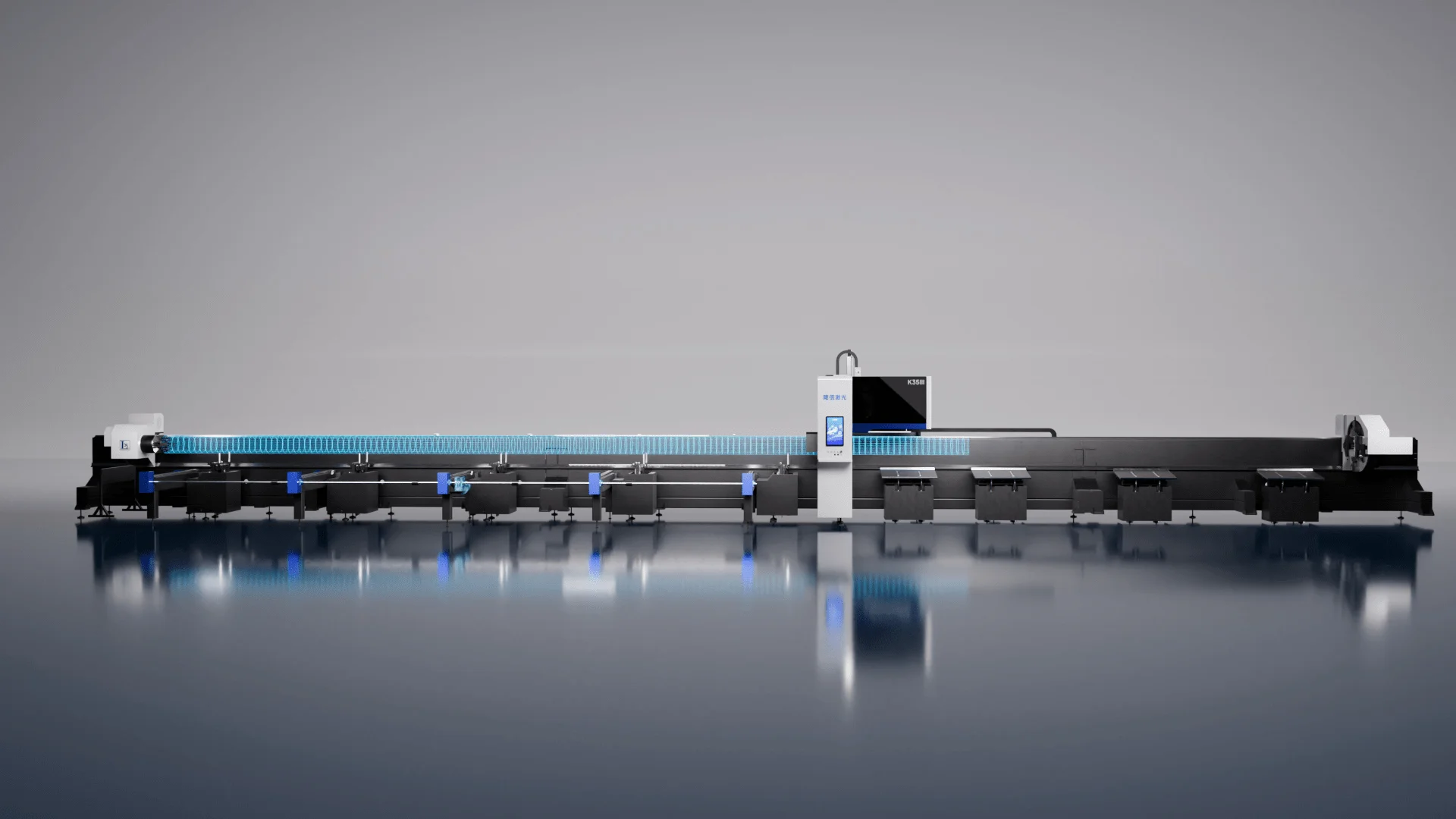

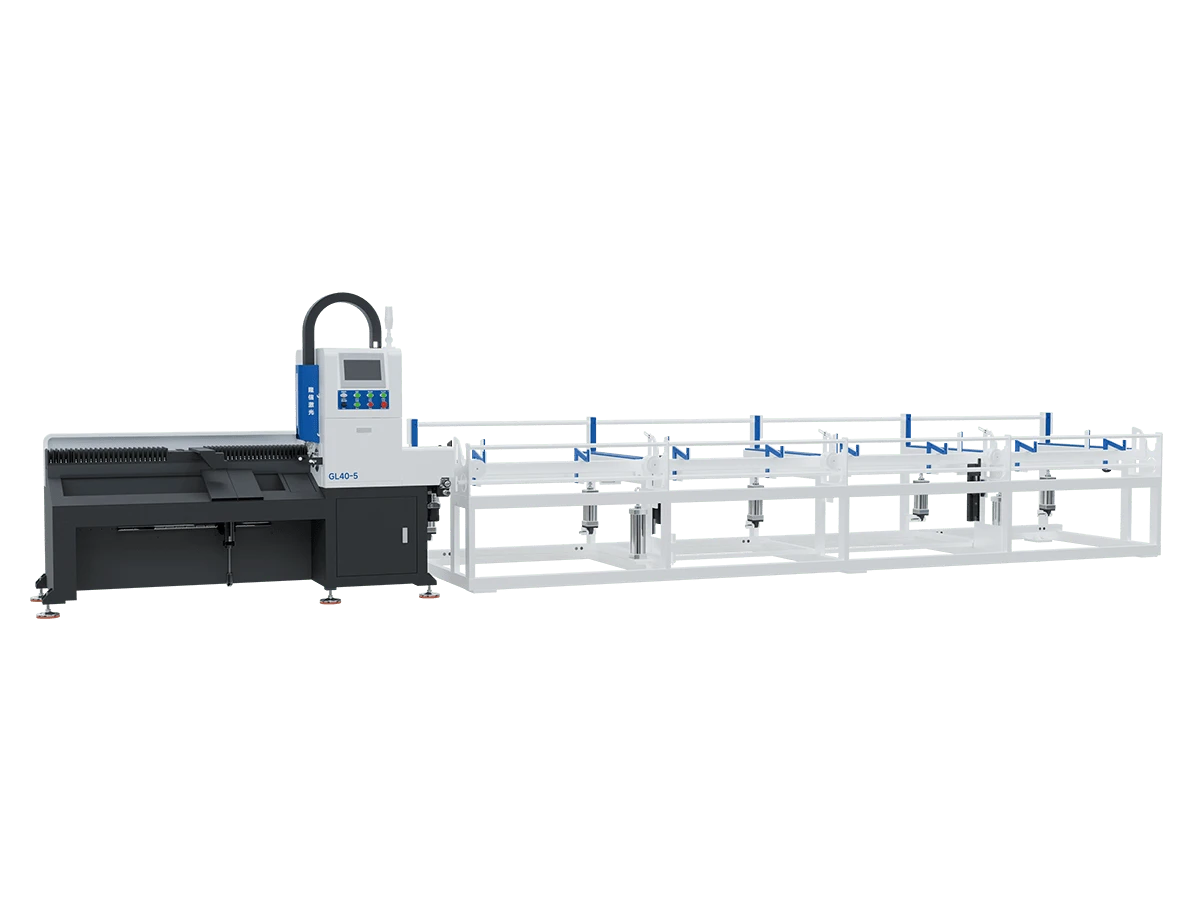

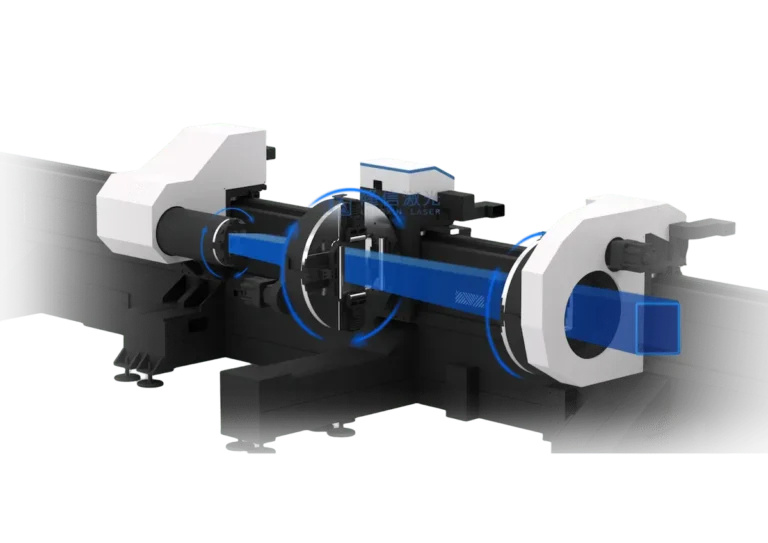

Heavy duty laser tube cutting machine

- Heavy duty laser tube cutters handle tube diameters of 200mm or more.

- Support high loads: single tube weights of 600kg to 1200kg, lengths of 12m or more.

- Equipped with high power lasers (≥3kW).

- Cut thicker walls (10mm to 15mm or more).

- Handle various pipe types: round, square, H-beam, channel, etc.

- Suited for heavy industries like bridges, oil pipelines, shipbuilding.

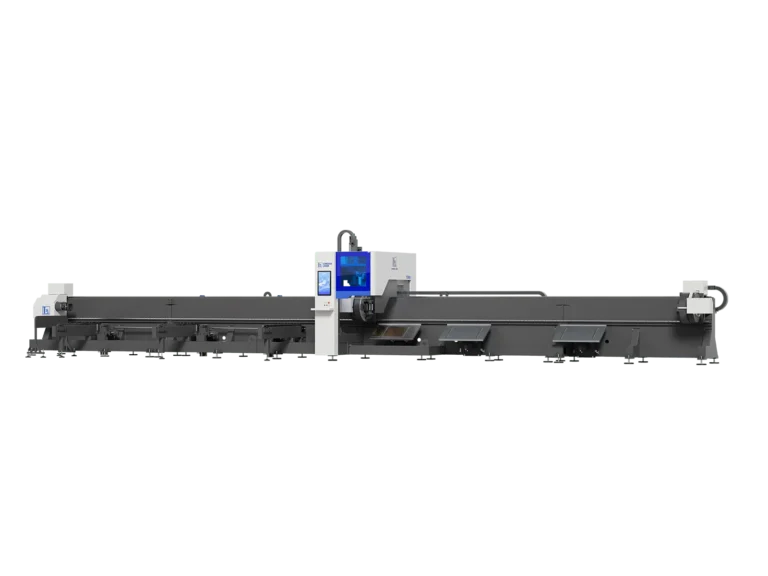

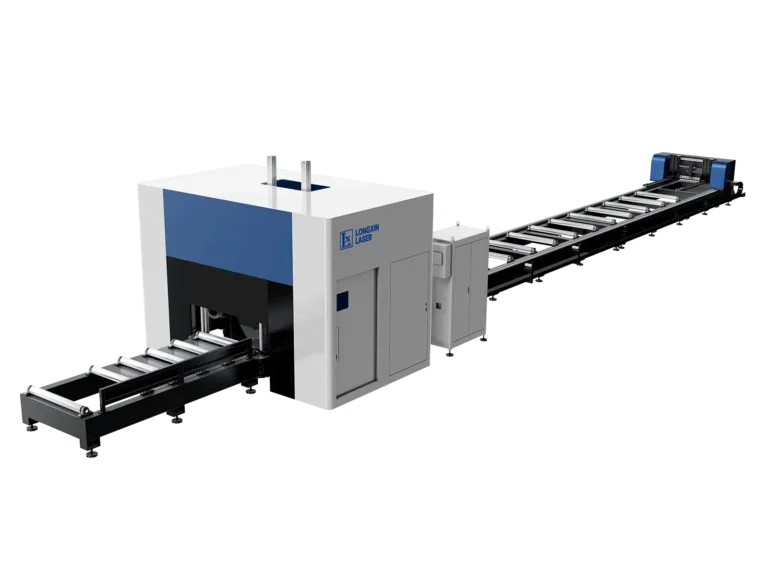

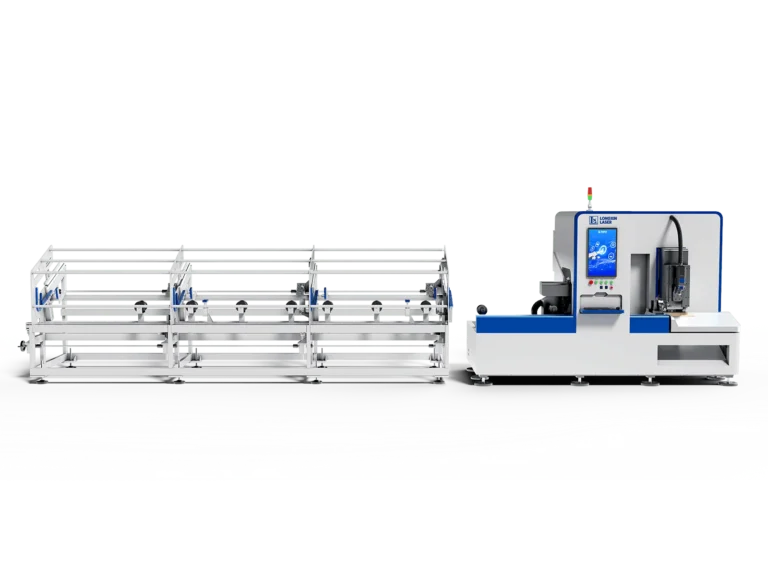

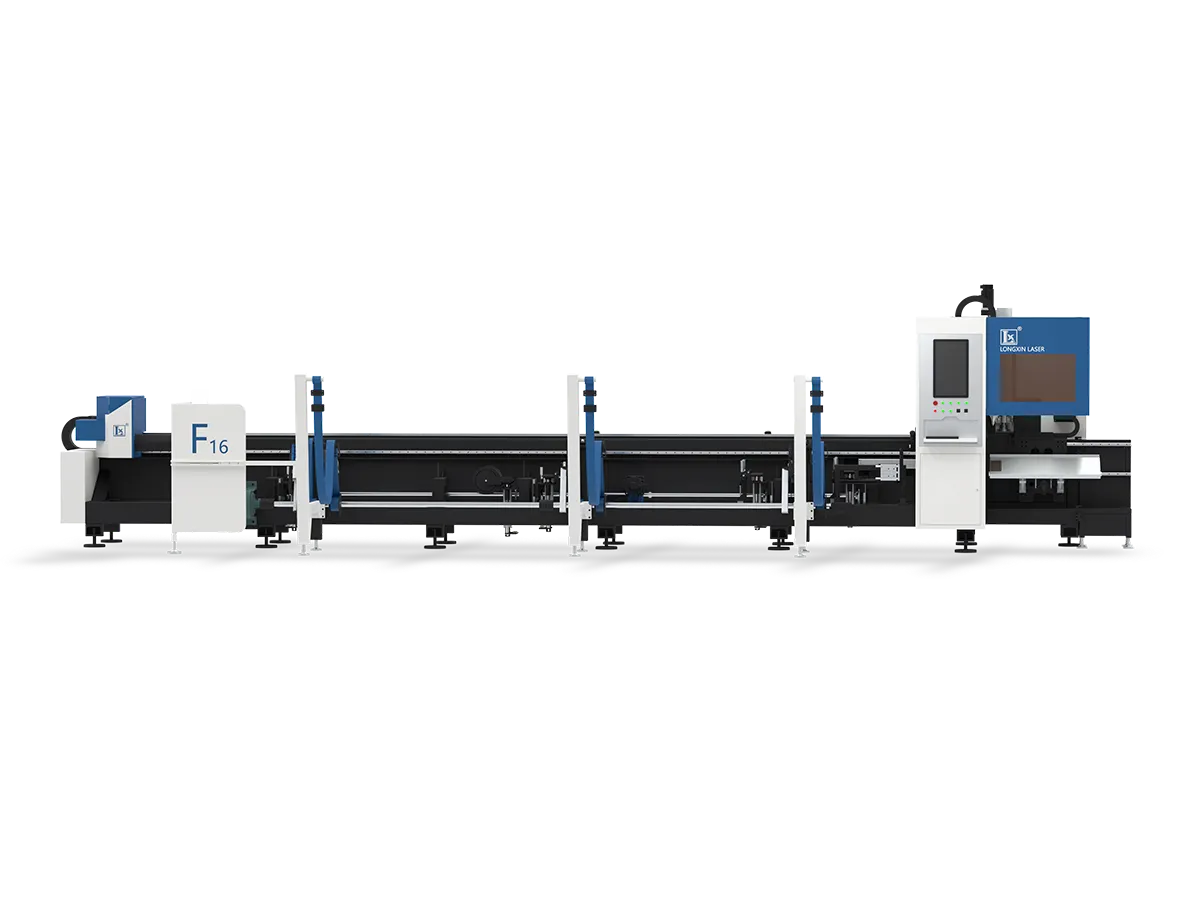

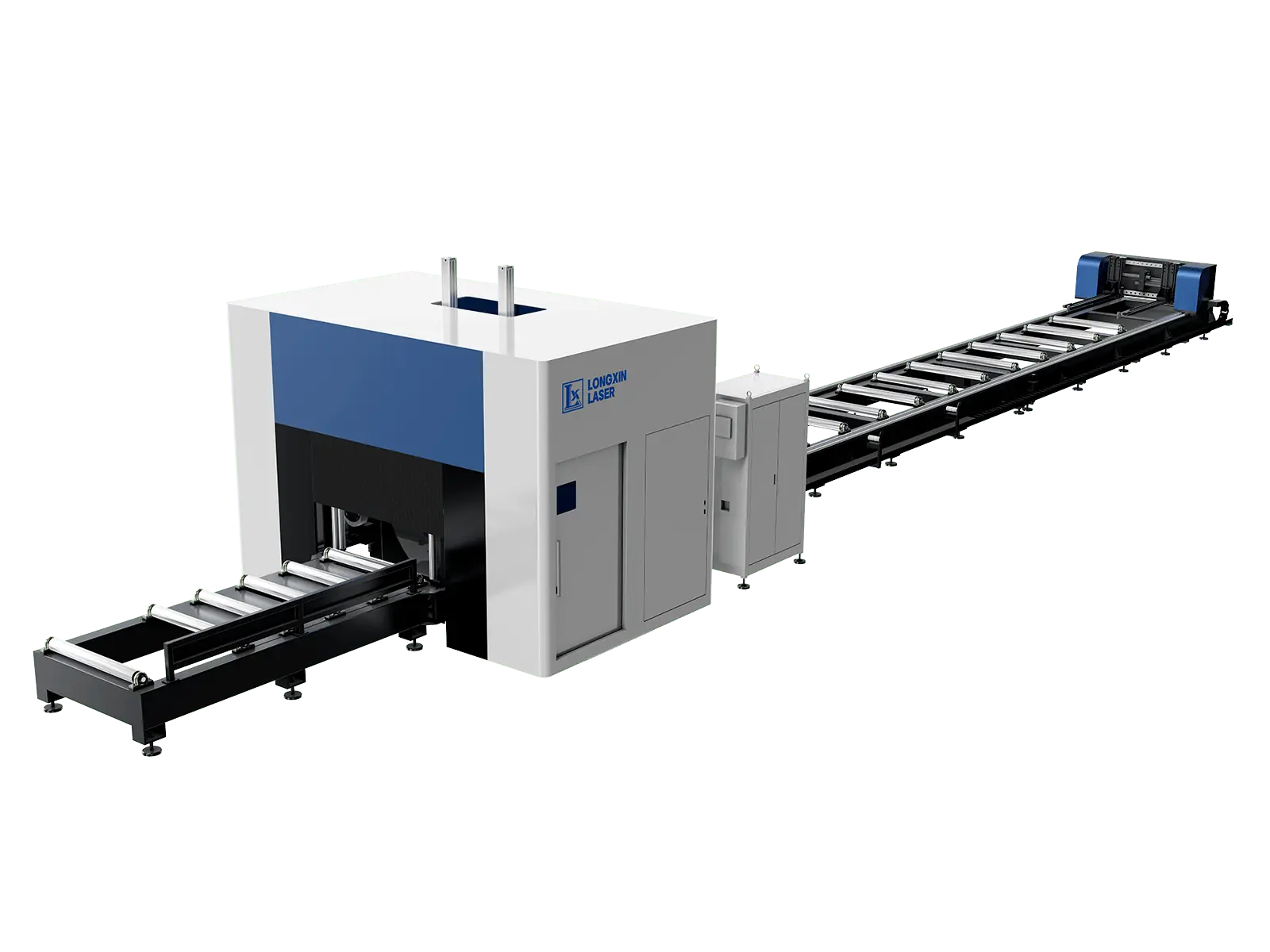

Profile laser cutting machines

Profile Laser Cutting Machines are specialized fiber laser machines designed to cut a wide range of metal profiles, including H-beams, C-channels, L-angles, and beveled pipes with high precision and efficiency. Widely used across industries such as steel structures, shipbuilding, elevator manufacturing, heavy industry, engineering machinery, and pressure vessel production.

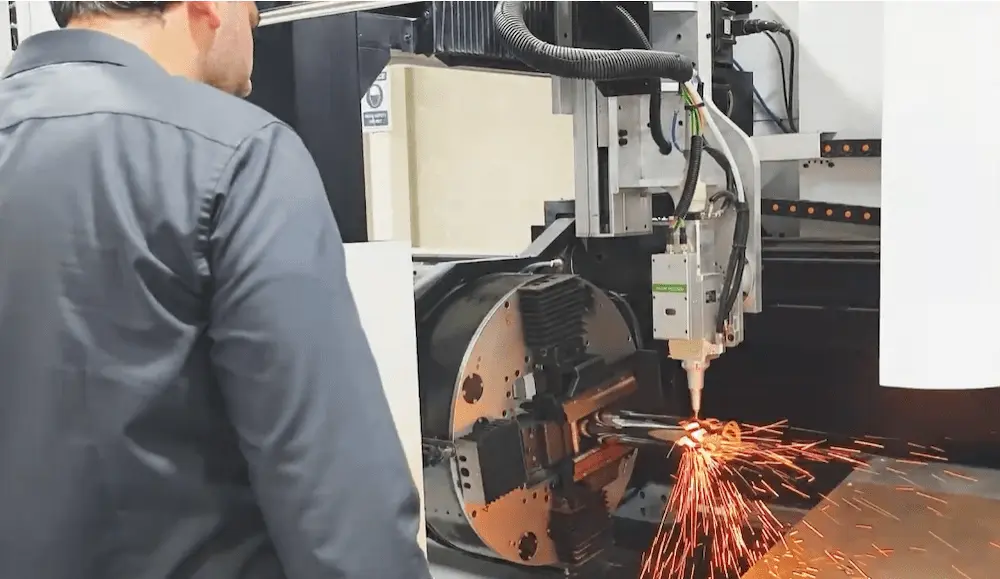

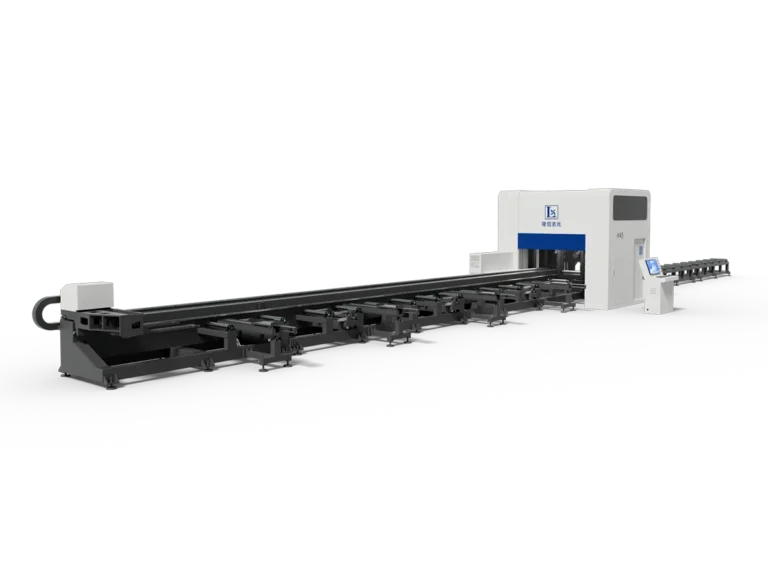

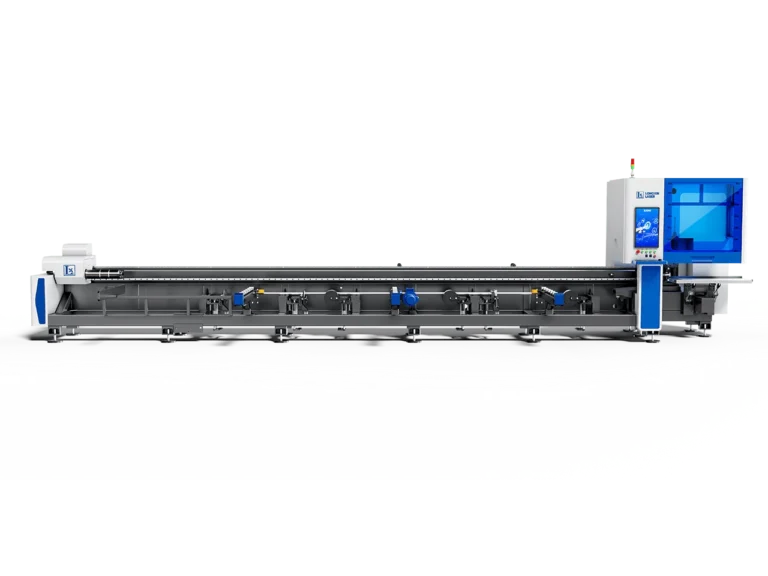

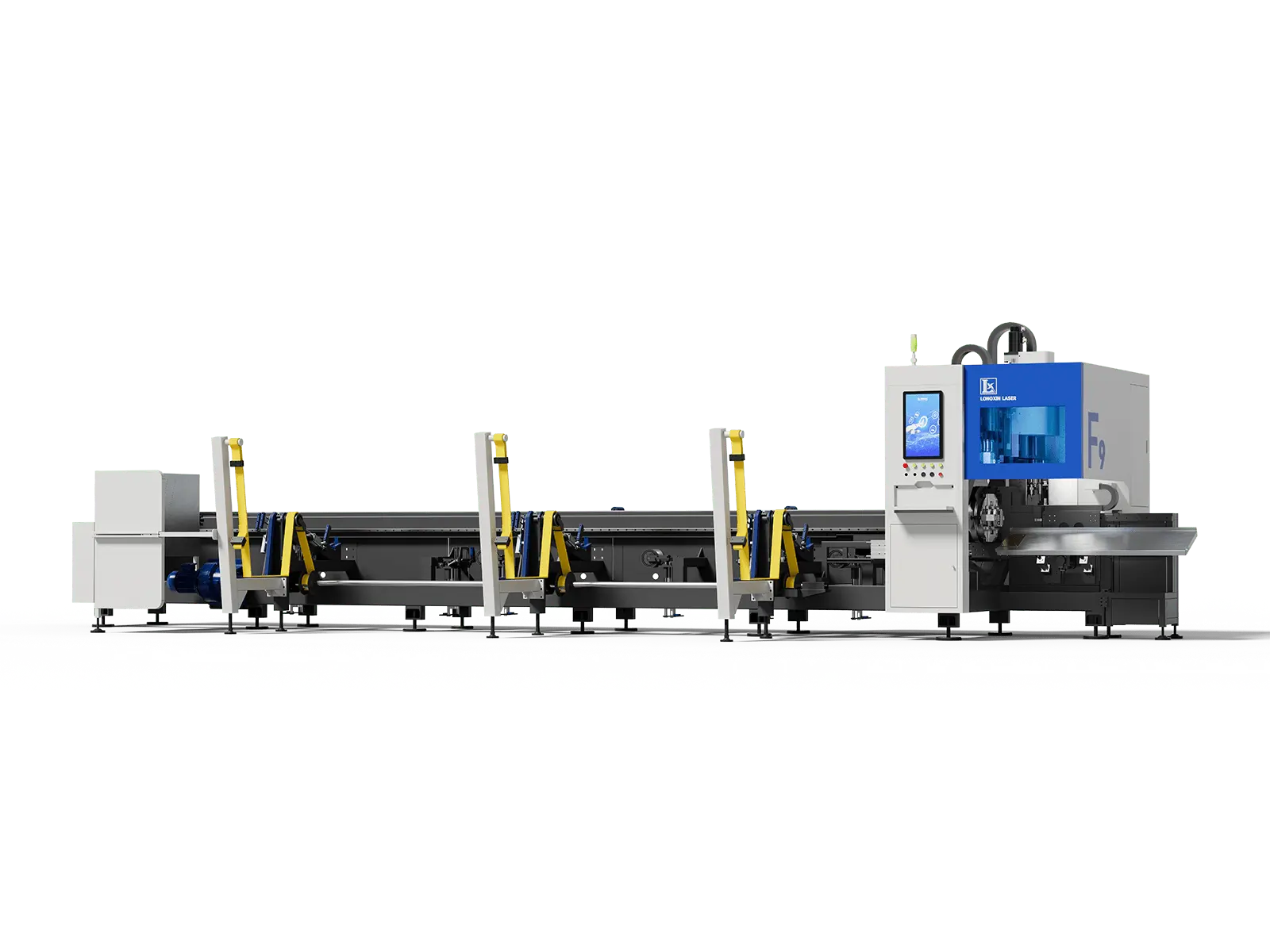

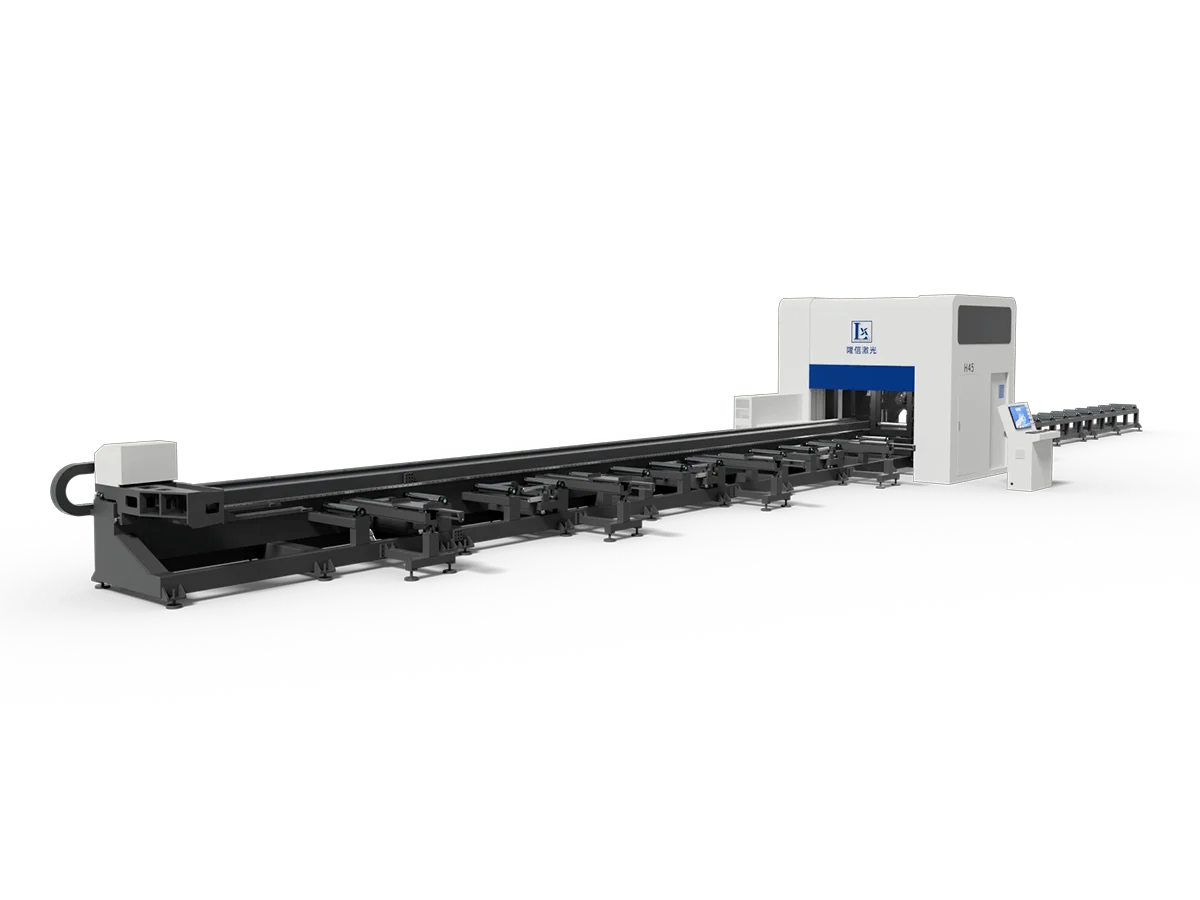

Bevel laser tube cutting machine

- Bevel (chamfer) laser tube cutting machine offers high-precision angled cuts on metal tubes.

- Ideal for seamless welding preparation and complex structural assembly.

- Equipped with 3D/5-axis fiber laser technology.

- Delivers accuracy of ±0.03mm for grooving, V-shaped, and Y-shaped bevel cuts up to 50 degrees.

- Ensures optimal edge geometry for welding or fitting.

Automation solutions

Longxin tube laser technologies

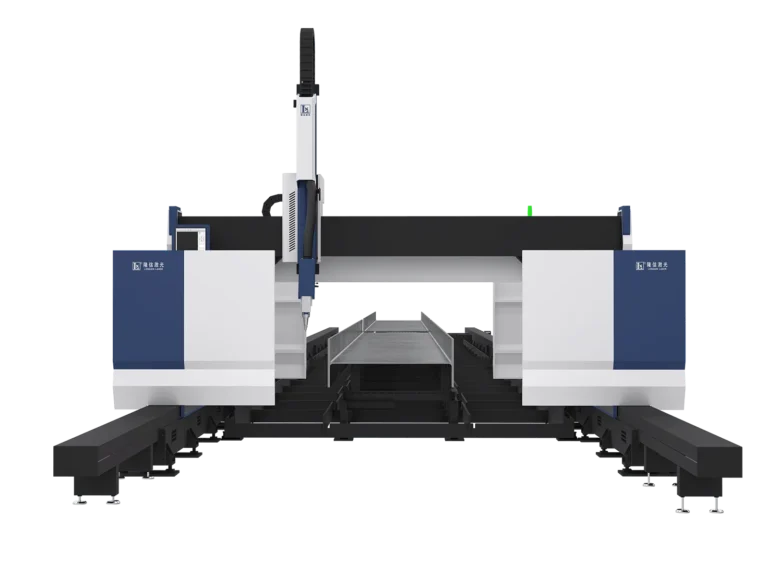

Heavy-Duty Chucks

3-4 chuck design for stable cutting of large-diameter tubes.

45° Bevel Cutting

3D rotating head for precise bevel and angled cuts.

Maximum acceleration 2.0G

Double the cutting efficiency — one machine performs like two.

Zero Tail Cutting

Ultra-short tail cutting enabled by laser head lifting and front chuck retraction.

Multifunctional Processing

Integrates four operations—cutting, thermal drilling, tapping, and marking—into one tube laser machine.

High Speed & Accuracy

Fiber laser source ensures fast cutting with ±0.03mm precision.

How to choose a tube laser cutting machine?

Choosing the right tube laser cutting machine is essential for achieving stable cutting quality, high productivity, and long-term cost efficiency. The ideal machine depends on your tube size, material, processing requirements, and production volume. Below is a practical guide to help you select the most suitable solution for your application.

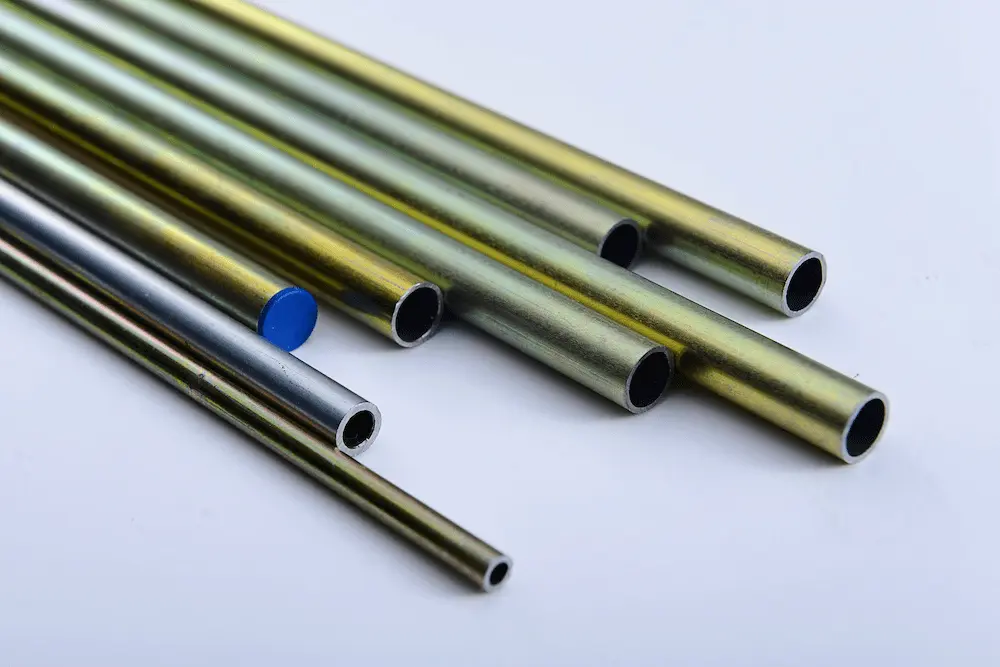

What kind of tubes can be cut by a laser tube cutter?

- Tube shapes:round tubes, square tubes, rectangular tubes, elliptical/oval tubes, triangular tubes, trapezoidal tubes, hexagonal tubes, concave tubes, waist-type tubes, irregular/special-shaped tubes.

- Profile and structural shapes: L-shaped profiles (angle steel), c-shaped profiles (channel steel), u-shaped profiles, h-shaped profiles (h-beams), t-shaped profiles, i-beams (universal beams), pfc channels (parallel flange channels), rsa sections (rolled steel angles), wide flange beams.

What kind of metals can a laser tube cutter cut?

Tube diameter, length & weight capacity

Start by confirming the maximum tube diameter, length, and weight you need to process.

The chuck size determines the maximum clamping diameter, while the machine bed and feeding system define the supported tube length—typically ranging from 6 to 12 meters.

For heavy or long tubes, choose a machine equipped with follow-up or intelligent support systems to prevent sagging and vibration during rotation and feeding, ensuring consistent cutting accuracy.

Chuck design and clamping system

The chuck structure directly affects cutting accuracy and stability:

- Two-chuck machines are suitable for standard tube cutting tasks

- Three-chuck machines provide better support for long or heavy tubes and reduce tail material waste

- Automatic centering chucks improve efficiency and reduce setup time

For high-precision and batch production, a multi-chuck configuration is strongly recommended.

Processing requirements & optional functions

Beyond straight cutting, many applications require additional operations such as:

- Hole cutting and notching

- Bevel cutting for welding preparation

- Threading or tapping

If bevel cuts are needed, select a machine with a bevel cutting head (commonly up to ±45°).

For threaded holes or high-volume hole processing, optional drilling or tapping modules can significantly improve efficiency.

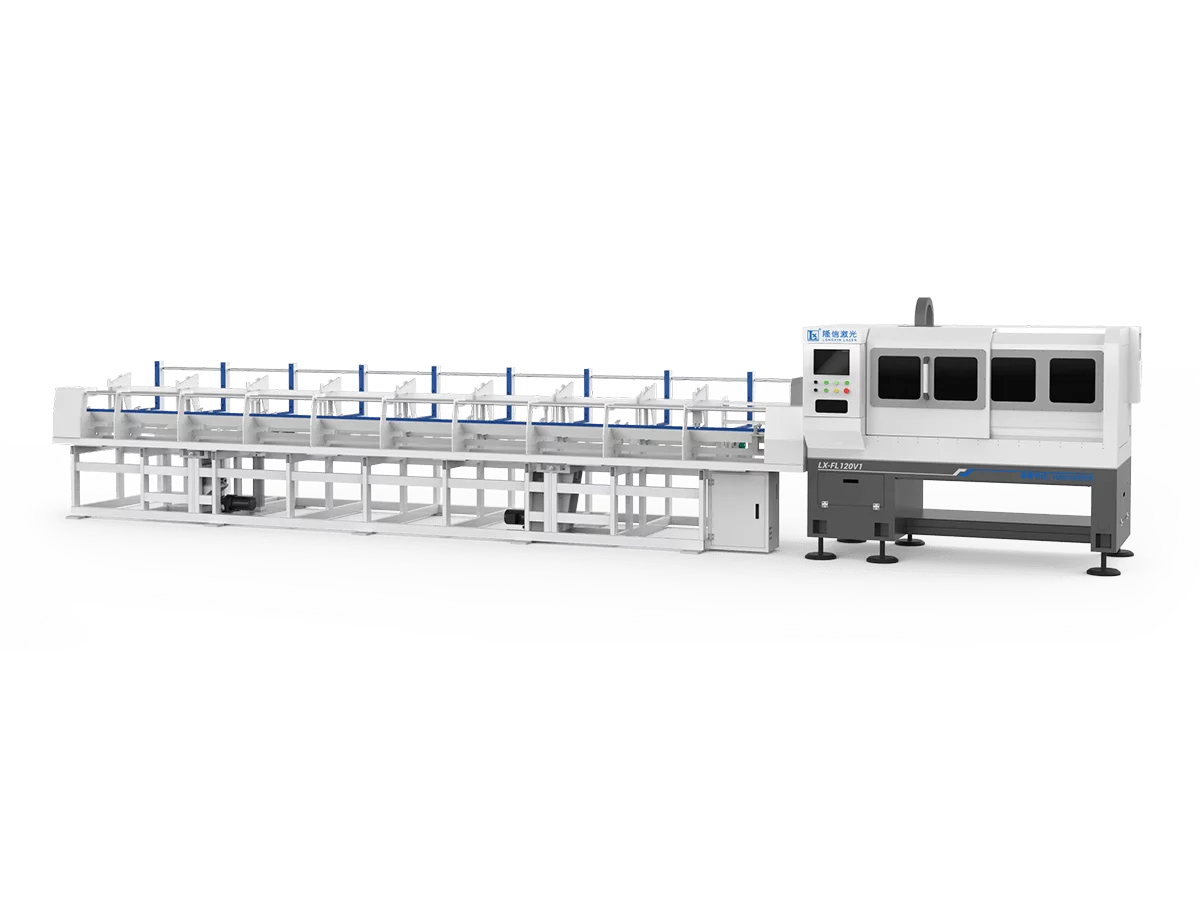

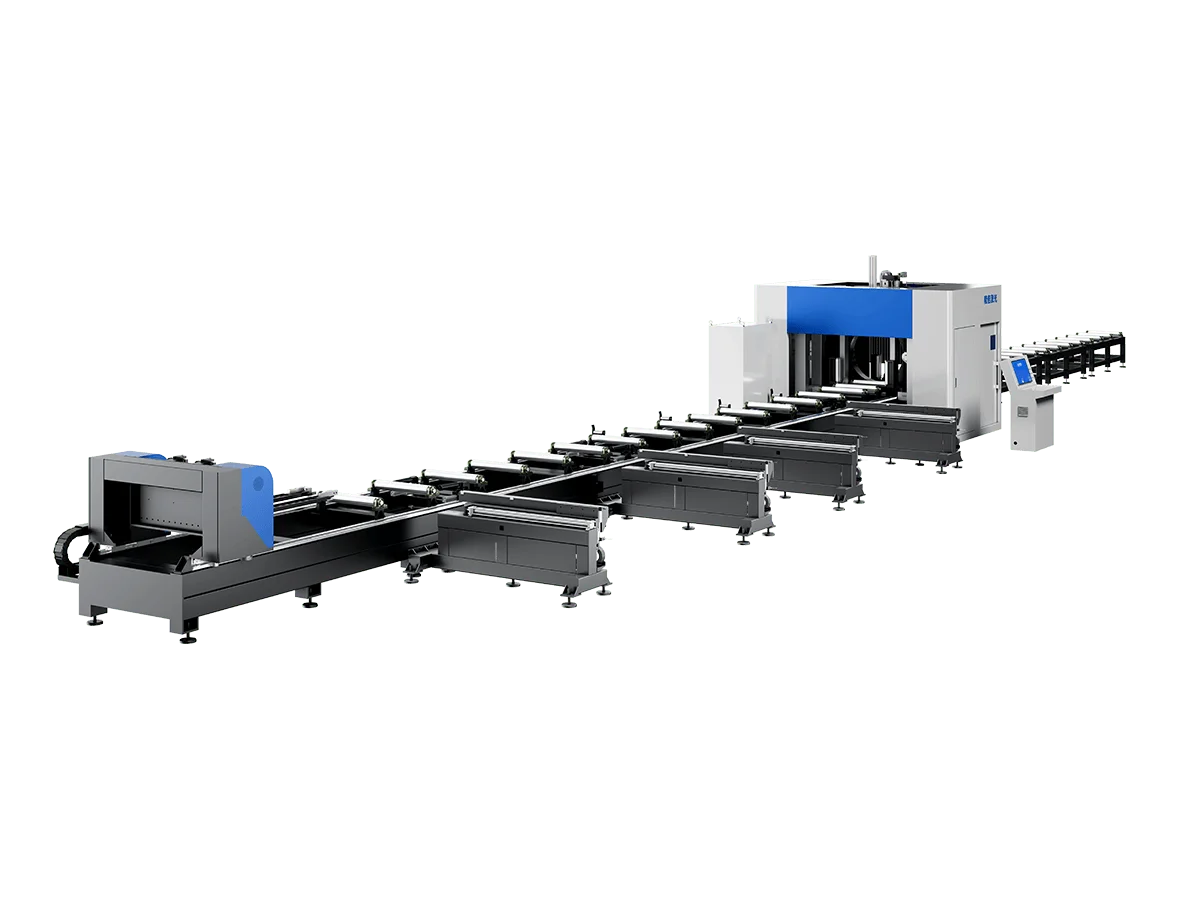

Automation and production efficiency

For manufacturers aiming to increase output and reduce labor costs, automation is a key factor:

- Automatic tube loading and unloading systems

- Servo-driven follow-up supports for long tubes

- Intelligent nesting and cutting software

An automated tube laser cutting machine can significantly improve productivity and consistency in mass production environments.

Blog

Learn more about laser tube cutting technology

Customer Cases