Tube laser cutting machines are profoundly changing the way tubes are traditionally processed, thanks to their high accuracy, speed, versatility, waste reduction and automation. Choosing the right tube laser cutting machine is critical to optimizing productivity, reducing costs and improving product quality. This article will give you a reference for the right selection of laser tube cutting machine.

1. Confirm Tube Diameter and Length

Maximum Tube Diameter:

Make sure the machine’s chuck/frame can grip your largest tube size. The chuck diameter itself refers to the maximum tube size it can clamp, so choosing the chuck just above the tube’s max diameter is ideal.

For instance, a Φ220 mm chuck can hold up to 220 mm tubes, a Φ350 mm chuck up to 350 mm, etc. Processing tube wall thickness of up to 12mm, the maximum diameter of the pipe φ220mm, the longest pipe length of 5.5m, only need to be cut off, with no need for perforation engraving and other processes. Then according to this requirement, we can match to chuck diameter φ220mm, 6m long equipment. These data are just enough to meet the needs of customers.

Maximum Tube Length:

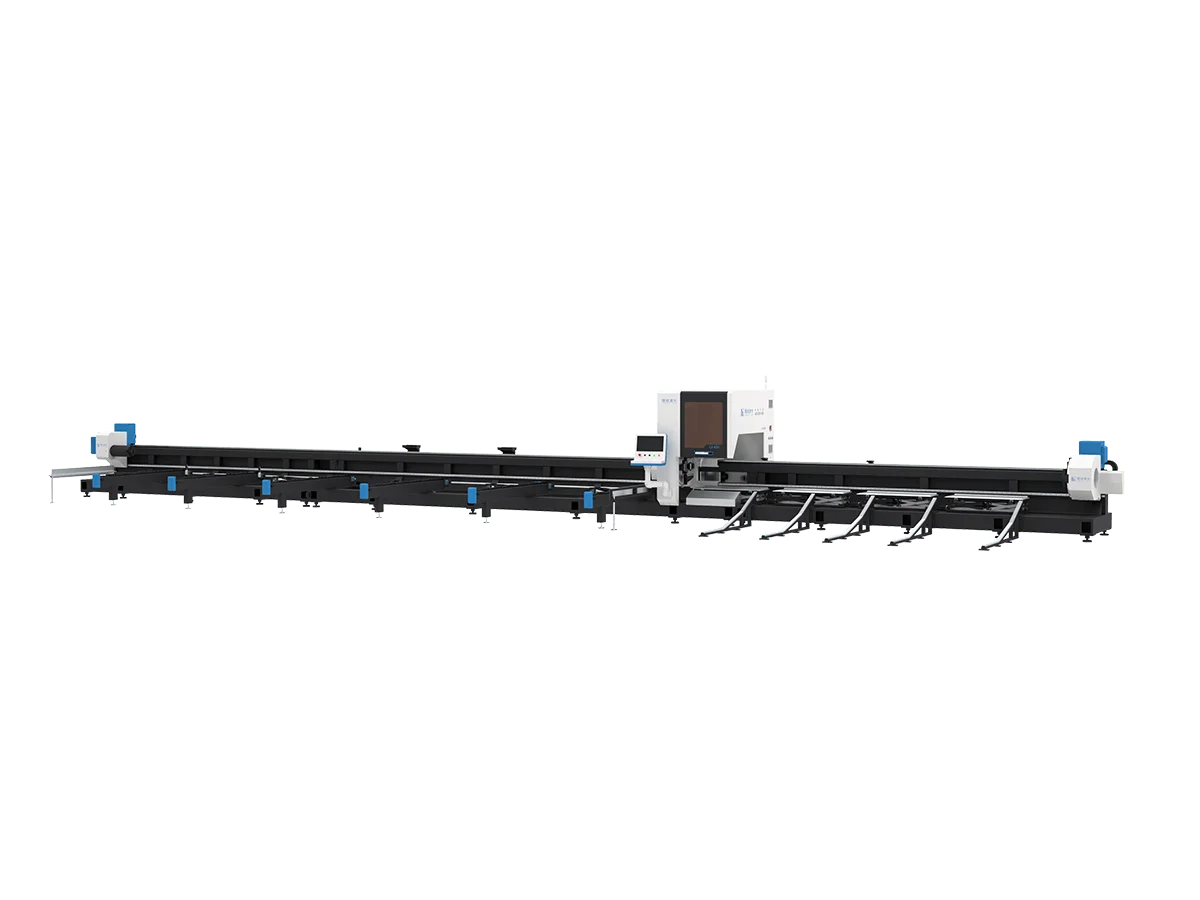

Check the tube laser cutting machine loader’s travel. Common models handle up to 6–12 m stocks. A longer bed machine with full feeding is ideal if you cut many short segments from longer stock.

The length of the tube also affects the feeding system of the laser tube cutting machine.

Adaptation of the feeding system

- Short tubes (<1 metre): suitable for manual feeding or simple automatic feeding systems.

- Medium length tubes (1-6 metres): need to be equipped with a standard automatic feeding and unloading system to increase productivity.

- Long length tubes (>6 metres): requires an enhanced automatic feeding system and supports to prevent the tube from bending or sagging during processing.

2. Confirm Tube Shape

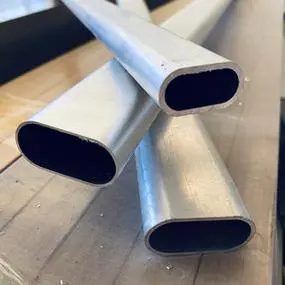

The cross-section shape of your tubes affects grip and cutting stability. Standard shapes – round, square, and rectangular – are easily handled by nearly all laser tube cutters.

Advanced machines support these shapes well; for example, one model cuts rectangular pipes up to 250×150mm. If your parts include special profiles (e.g. elliptical tubes, U/C-channels, “T” or “L” shapes, or custom extrusions), you may need extra gripping.

In general, the more irregular the profile, the more chucks (or independent jaws) are beneficial. A 4-jaw (four-chuck) setup is often recommended for highly irregular shapes (it provides an extra clamp for custom profiles). For slightly non-circular shapes (ovals, polygons, angled tubes), a 3-jaw system usually suffices but pay attention to alignment.

Round/Rectangular/Square Tubes:

Standard tube lasers (with 2 or 3 chucks) handle these without issue. Just ensure the chuck jaws or collets match the tube form. Multi-faceted shapes like squares often have dedicated square adapters.

Irregular Profiles:

Elliptical or non-symmetric tubes are harder to center and cut. If you need to cut many such profiles, choose a machine with at least 3 chucks (for extra support) and ask if a 4th chuck option exists . The extra chuck grips the tube more firmly, improving accuracy on odd shapes.

Complex Open Sections:

Items like I-beams, channels, or “H” tubes should be checked case-by-case. Some tube lasers can be equipped with special clamps or rollers to hold open sections; discuss these with the supplier if needed.

3. Confirm Tube Processing Requirements

Beyond straight cutting, determine any additional machining your tubes need. Many applications require holes, notches, bevels, or threads on the tubes:

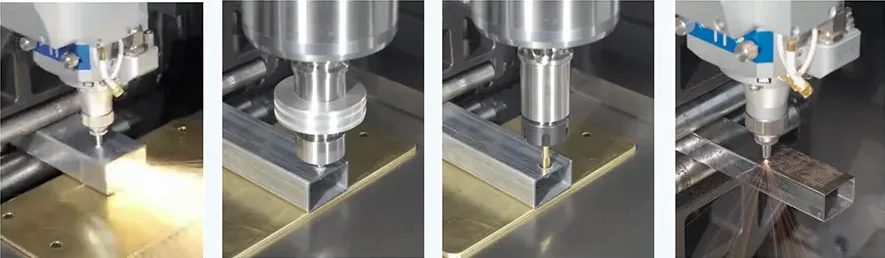

Hole Drilling/Punching:

Lasers can make holes by dwelling on a spot or using a high-power pulse, but this is slow. If you need many drilled holes or slots, see if the machine offers a drill/piercing attachment. Some tube lasers integrate a small CNC drill or punch for holes and notches, which can be much faster than pure laser drilling for large or long runs.

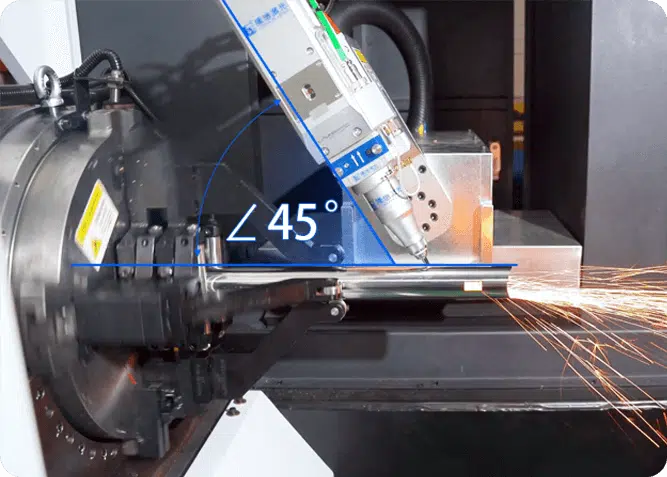

Bevel Cutting:

If the design needs angled ends (weld preparation), you should choose a machine with a bevel-head option (For example, LX-T16 Bevelling Laser Pipe Cutting Machine). A bevel head tilts the laser (commonly up to 45°) to produce angled cuts. This is an optional module on many machines. If you skip a bevel head, the machine will only make perpendicular cuts.

Tapping/Threading:

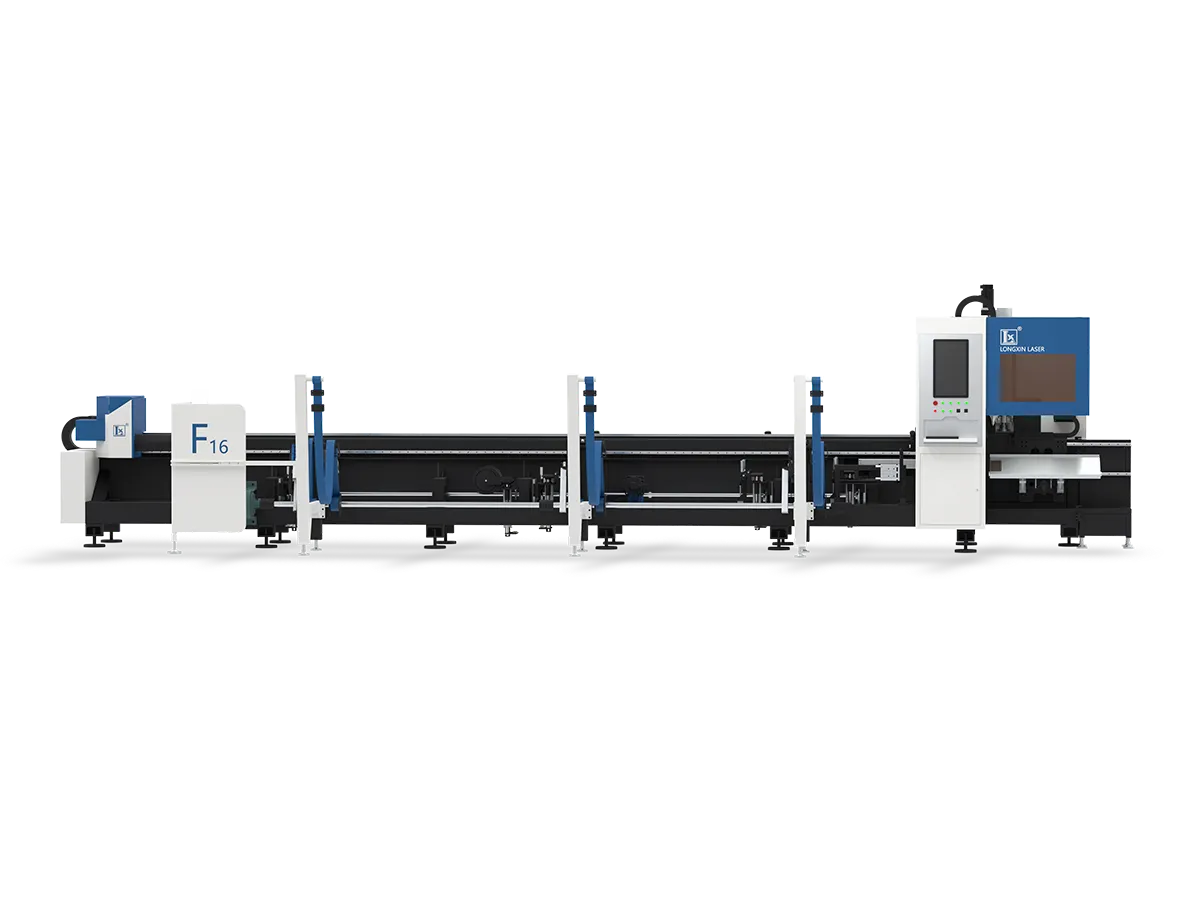

Standard lasers do not cut screw threads directly. Tapping is typically done with a mechanical tap or thread mill. Some advanced tube lasers (LX-F16) offer an optional automatic tapping or thread-milling tool that can be used in one setup. If your parts need threaded ends or holes, ask whether the machine can integrate a tapping unit or if tapping must be done separately after cutting.

4. Confirm Tube Weight and Stability

Heavy or long tubes require extra caution. A heavy-walled pipe or a very long bar can sag under its own weight, which affects cutting quality. When you are evaluating machines, please check:

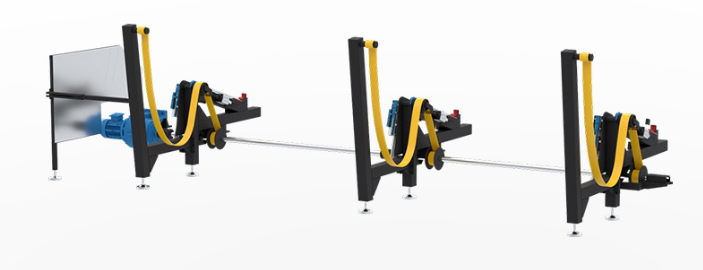

Support Systems:

A robust support system is vital. Many tube lasers use floating tail supports that move with the carriage. This “follow” support keeps the tube height constant as it is fed, preventing sag. With a floating support the loading and rotating process stays stable and tube sag is avoided.

Some vendors call advanced versions “intelligent support” – they automatically adjust to the tube’s contour or flex. Always pick a machine with supports spaced close to the cutting head for heavy work.

Weight Limits:

Verify the maximum tube weight the machine can handle. This is usually given as “max weight per meter” for a tube. Exceeding this can overload motors or cause misfeeds. If you work with very thick steel (heavy density) tubes, choose a machine designed for that load.

Loading Equipment:

For very heavy tubes, you may need a built-in loader or crane interface. Some machines include an integrated clamp table or automated lift for heavy pipes.

5. Confirm Chuck Configuration (2-chuck or more?)

You should have already decided on the size of the chuck according to the diameter of the tube and the length of the cut, and then you need to think about the stability of the laser cutting process, the accuracy and the tail waste. In general, the number of chucks (jaws) determines the stability of the machine’s pipe clamping as well as the tail waste.

2-Chuck Systems:

These have one fixed chuck at the head and one movable tailstock chuck. They are simpler and generally cheaper, suitable for straightforward round or square tubes. Two-chuck machines are common for small to medium work.

Ordinary two chuck laser tube cutters usually leave a long scrap tail (the part of the tube between the last cut and the end) because once the cut is within reach of the chuck, any remaining stump becomes scrap. In addition, with only two clamping points, very heavy or very long tubes are more likely to deform.

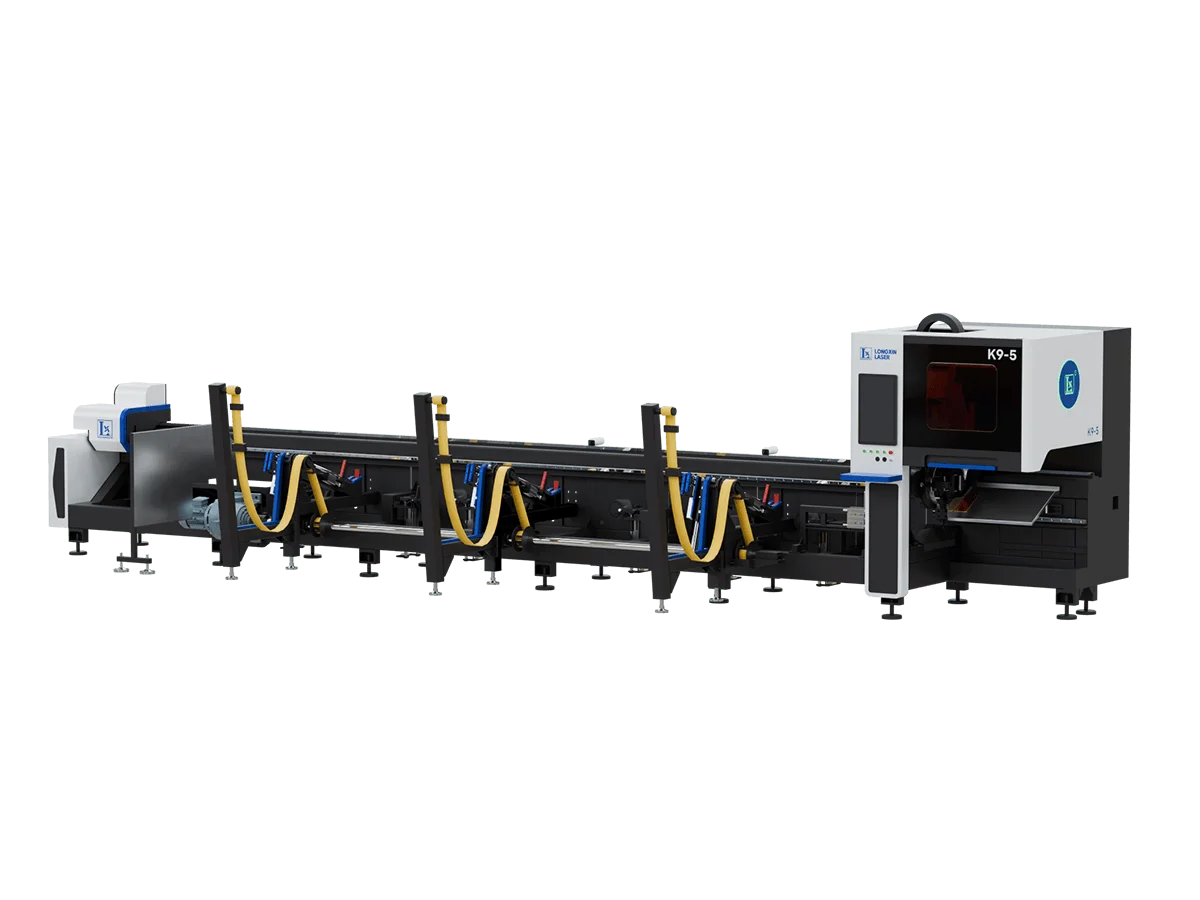

However, as the technology continues to iterate, in 2025 there are already laser tube cutting machine (LX-K9-5) that use only two chucks to achieve 0 ends, comparable to the results of three chucks. The technical principle is that before cutting the last part of the tube, the laser cutting head lifts up, allowing the front chuck to move forward and clamp the tube out of the rear carat, achieving 0-tail material processing at the end.

3-Chuck Systems:

Here, 2 chuck drive the tube and a third (usually fixed near the headstock) provides an extra clamp mid-length. This configuration locks the tube more firmly, which improves cutting accuracy on longer parts and reduces vibration. Importantly, a 3-chucks system can feed the tube fully, often achieving zero tail waste as the machine pushes the entire tube through.

Manufacturers note that 3-chuck laser tube cutters are versatile and cost-effective (cheaper than adding a whole extra head). The downside is slightly higher complexity and price than a 2-chuck machine, but with higher throughput and efficiency.

Choice Tip:

- If your tube work is primarily standard shape cutting and moderate lengths, a regular 2 chuck laser tube cutter will suffice.

- If you want to minimise tailing, a 2 chuck machine with front chuck avoidance, or a regular 3 chuck machine is more worth the investment.

- For complex profiles, high-precision, heavy-duty, and extra-long tubes, a customised laser tube cutting machine, possibly with 4 or more chucks, is required.

- More chucks are not always better. An increase in the number of chucks means a redesign of the mechanical structure, which can significantly increase the cost of the machinery and usually requires customisation, which is time-consuming.

6. Automation (Loading/Unloading) needs

For high-volume or heavy work, consider machines with automatic loading and unloading systems. These use conveyors or robotic arms to feed tubes into the laser and remove cut parts, drastically increasing throughput and reducing manual labor. Auto-loading is optional but valuable if you cut many similar tubes; it also improves safety (no manual lifting).

If budget is tight and volumes are low, you can load tubes by hand, but ensure you have means (like a clamp table) to manually secure them.

Support Systems (Follow/Intelligent)

Beyond the basic tailstock, modern machines offer enhanced tube support:

- Floating (Follow) Support: This support rolls on rails under the tube and moves along with the cutting head. It keeps supporting the end of the tube continuously as it feeds, preventing the rear from sagging or vibrating. This is essential for long or very flexible tubes.

- Fixed Tailstock: Older or simpler machines use a fixed tailstock that doesn’t move. This is fine for short lengths, but as soon as you cut away the tube end, the remaining part can droop once it’s only supported at one end.

- Intelligent Support: Some advanced cutters have sensors that detect tube curvature or deflection and automatically adjust the support height. This “smart” system maintains a constant focus-to-tube distance even on warped tubes. If you deal with bent or inconsistent material, ask about this feature.

7. Choose a Laser Tube Cutting Machine Based on Processing Accuracy

(1) High-Precision Applications (Medical Devices, Electronic Components)

Key Requirements: Cutting accuracy ≤±0.05mm, smooth cut surfaces, minimal heat-affected zones.

Equipment Configuration Requirements

| Component | Specifications |

| Laser Source | Fiber laser, 1500-3000W power, beam quality M²<1.1 |

| Beam Spot Diameter | ≤0.02mm (ultra-fine spot for thin materials) |

| Repeat Positioning Accuracy | X/Y-axis: ±0.03mm, Rotary axis: ±0.05° |

| Machine Rigidity | Cast iron bed + FEA-optimized structure, vibration resistance ≥50Hz |

| Cutting Head | Auto-focus cutting head with ceramic nozzle (1.0-1.5mm aperture) |

| Control System | Pulse cutting capability, process database, real-time monitoring |

| Auxiliary Systems | High-purity nitrogen (≥99.999%), water chiller (±0.5°C stability) |

Process Optimization

- Parameters: Speed 1-2m/min (1mm stainless steel), pulse frequency >2000Hz

- Gas Selection: Nitrogen for stainless steel (12-15bar), oxygen for carbon steel (8-10bar)

- Typical Applications: Surgical instrument brackets (0.5mm titanium alloy), micro-connectors (1mm copper alloy)

(2) Medium-Thick Material Batch Production (Construction, Heavy Machinery)

Key Requirements: Cutting thickness 8-20mm, high efficiency, continuous operation stability.

Equipment Configuration Requirements

| Component | Specifications |

| Laser Source | Fiber laser, 4000-12000W power, power fluctuation <±2% |

| Beam Spot Diameter | 0.05-0.1mm (balances speed and precision) |

| Repeat Positioning Accuracy | X/Y-axis: ±0.05mm, Rotary axis: ±0.1° |

| Machine Rigidity | Welded steel structure with cross-bracing, load capacity ≥2000kg |

| Cutting Head | Anti-reflection coating, quick-change nozzle design |

| Control System | Batch file processing, automatic nesting |

| Auxiliary Systems | Dual-pump water cooling (±1°C stability), dust removal ≥6000m³/h |

Process Optimization

- Parameters: Speed 0.5-1.5m/min (12mm carbon steel), oxygen assist (1.5-2MPa)

- Efficiency: Automatic loader integration, nozzle change time <10s

- Typical Applications: Bridge steel structures (16mm Q355), hydraulic cylinder tubes (10mm 45# steel)

(3) Special Material Processing (Titanium Alloy, Galvanized Steel)

Key Requirements: Handling reflective/oxidizable/high-melting-point materials.

Equipment Configuration Requirements

| Component | Specifications |

| Laser Source | Disk laser or anti-reflection fiber laser, ≥6000W power |

| Beam Spot Diameter | 0.03-0.06mm (high energy density) |

| Repeat Positioning Accuracy | X/Y-axis: ±0.04mm, Rotary axis: ±0.08° |

| Machine Rigidity | Fully enclosed splash-proof structure, corrosion-resistant coating |

| Cutting Head | Gold-coated mirrors + dual gas channels (independent inner/outer gas control) |

| Control System | Material database (pre-loaded parameters for titanium/galvanized steel) |

| Auxiliary Systems | Dual gas supply (nitrogen + compressed air), zinc fume filtration |

Process Optimization

- Titanium Cutting: Argon shielding (prevents oxidation), focus position offset -0.2~-0.5mm

- Galvanized Steel: Pre-purge mode removes zinc layer, 20% lower gas pressure

- Typical Applications: Aerospace titanium tubing (5mm TC4), HVAC ducts (3mm SGCC)

(4) General Metal Tube Processing (Furniture, Windows/Doors)

Key Requirements: Cutting thickness 1-6mm, cost-effectiveness, easy maintenance.

Equipment Configuration Requirements

| Component | Specifications |

| Laser Source | Fiber laser, 1000-2000W power, cost-optimized |

| Beam Spot Diameter | 0.05-0.1mm |

| Repeat Positioning Accuracy | X/Y-axis: ±0.1mm, Rotary axis: ±0.2° |

| Machine Rigidity | Lightweight welded structure, load capacity ≥500kg |

| Cutting Head | Manual focus adjustment, copper nozzle (200hr lifespan) |

| Control System | User-friendly interface, CAD direct import |

| Auxiliary Systems | Single-pump water chiller (±2°C), standard air compressor (0.8MPa) |

Process Optimization

- Parameters: Speed 2-4m/min (2mm carbon steel), oxygen assist (0.6-0.8MPa)

- Cost Control: Compressed air instead of nitrogen (acceptable for thin stainless steel)

- Typical Applications: Stainless steel railings (3mm 304), aluminum window frames (2mm 6061)

(5) Summary: Scenario-Based Selection Logic

| Scenario | Priority Order | Budget Allocation |

| High-Precision | Precision > Stability > Power | 60%+ on equipment |

| Medium-Thick Batch | Power > Efficiency > Maintenance | 50%+ on laser source |

| Special Materials | Specialization > Power > Safety | 40%+ on gas systems |

| General Processing | Cost > Usability > Basic Accuracy | 80%+ on base machine |

Note: Always request sample cutting tests to verify machine-material compatibility.

8. Optional Process Modules For Laser Tube Cutting Machine

Many tube lasers can add specialized modules. Consider these if your work demands:

(1) Beveling Head:

This tilts the laser head (commonly ±45° or more) to cut angled ends for weld joints. Specify the required maximum bevel angle. Not all machines include this by default.

(2) Drilling/Tapping Unit:

Some systems have an optional drill or tapping tool to make holes or threads. If you need threaded holes in tube walls, either a tap-up kit or a combined laser/tap machine is needed.

(3) Roll-Bending or Forming:

Occasionally, combined machines can also bend or form tubes. If so, these will be advertised as specialized multi-function units.

(4) Material Handling Attachments:

Options like bundle loaders (for multiple tubes at once), cross-cutting attachments, or stackers may be offered for higher automation levels.

Conclusion

List all your tube specs (sizes, shapes, materials, wall thicknesses, required operations) and go down this checklist. Compare suppliers’ machine data to ensure each critical attribute is covered. Choosing the right tube laser cutter involves balancing your tube characteristics against the machine’s features (diameter/length capacity, chuck type, supports, power, and optional modules) to find the best fit for your production needs.